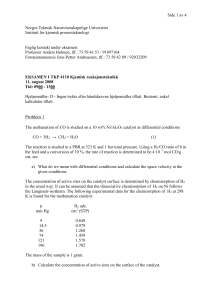

Lecture 10 (19th May 2004) - Hong Kong University of Science and

advertisement

Catalyst Design and Preparation Dr. King Lun Yeung Department of Chemical Engineering Hong Kong University of Science and Technology CENG 511 Lecture 3 Design of Catalyst (1) Stoichiometric analysis of target reaction (2) Thermodynamic analysis (3) Molecular mechanism (4) Surface mechanism (5) Reaction pathway (6) Catalyst properties (7) Catalytic materials (8) Propose a catalyst Case Study Methane Partial Oxidation to Formaldehyde CH4 + O2 CH2O + H2O DH = -76.8 kcal/mol DG = -70.9 kcal/mol Current Technology CH4 + H2O CO + 3H2 CO + 2H2 CH3OH CH3OH + 0.5 O2 CH2O + H2O Poor efficiency high energy and material cost Stoichiometric Analysis-1 (1) List all possible stoichiometric chemical equations (2) Calculate the DH and DG of reaction (3) Chemical bond changes Primary Reactants CH4 O2 Reactant Self-interactions 2CH4 C2H6 + H2 2CH4 C2H4 + 2H2 2CH4 C2H2 + 3H2 O2 = none DH DH DH DG = 8.5 kcal/mol DG = 12.8 kcal/mol DG = 22.2 kcal/mol Stoichiometric Analysis-2 Reactant Cross-interactions CH4 + 0.5 O2 CH3OH CH2O + H2 CO + 2H2 CH4 + O2 CH2O + H2O HCOOH + H2 CO + H2 + H2O CO2 + 2H2 CH4 + 1.5O2 CH2O + H2O2 HCOOH + H2O CO + 2H2O CO2 + H2 + H2O OI OI, DH OI, DH DG = -20.6 kcal/mol DG = -20.0 kcal/mol DG = -43.1 kcal/mol OI, DH, O OI, DH, O OI, DH, O OI, DH, O DG = -70.9 kcal/mol DG = -67.0 kcal/mol DG = -87.3 kcal/mol DG = -90.5 kcal/mol OI, DH, O OI, DH, O OI, DH, O OI, DH, O DG = -31.0 kcal/mol DG = -119.8 kcal/mol DG = -136.5 kcal/mol DG = -139.8 kcal/mol Stoichiometric Analysis-3 Reactant Cross-interactions CH4 + 2O2 HCOOH + H2O2 OI, DH, O CO + H2O2 + H2O OI, DH, O CO2 + 2H2O OI, DH, O DG = -98.6 kcal/mol DG = -118.7 kcal/mol DG = -189.5 kcal/mol Reactant-Product interactions CH4 + C2H6 C3H8 + H2 CH4 + C2H4 C3H8 CH4 + CH3OH C2H5OH + H2 DG = 16.6 kcal/mol DG = 4.5 kcal/mol DG = 10.5 kcal/mol etc. DH, A A DH, A Thermodynamic Analysis (1) Assess thermodynamic feasibility (rank by DG) (2) Rank and group reactions with common trend CH4 + 2O2 CO2 + 2H2O CH4 + O2 CH2O + H2O CH4 + O2 HCOOH + H2 CH4 + 0.5 O2 CH2O + H2 CH4 + 0.5 O2 CH3OH CH2O CO + H2 CH3OH CH2O + H2 OI, DH, O OI, DH, O OI, DH OI, DH OI DH DH DG = -189.5 kcal/mol DG = -70.9 kcal/mol DG = -67.0 kcal/mol DG = -20.0 kcal/mol DG = -20.6 kcal/mol DG = -17.0 kcal/mol DG = 2.0 kcal/mol Reaction Mechanism (1) Visualize molecular events leading to formation of desired product(s) (2) Eliminate non-plausible pathways CH4 + 0.5 O2 CH2O + H2 Surface Mechanism (1) Guess the most plausible surface mechanism that lead to the desired product(s) (2) Research known adsorption, molecular configurations of reactants and products CH4 CH3-S CH2-S O2 2O-S CH3OH CH2O, H2 Reaction Pathways (1) Based on the analysis of surface mechanism establish the desired reaction pathways for the reaction CH4 + 0.5 O2 CH2O + H2 DG = -20.0 kcal/mol OI, DH (1) Must promote oxygen insertion (OI) (2) Must be a mild dehydrogenation (DH) (3) Must prevent strong dehydrogenation (4) Must prevent oxidation O2 CH4 H CH3 CH2O O O CH3 H O Catalyst Properties (1) Identify the desired catalyst properties based on surface mechanism/reaction pathway (1) Oxygen adsorption site leading to dissociated and immobile oxygen species (2) Mild dehydrogenation to produce CH3 (3) Adjacent sites to facilitate final dehydrogenation O2 CH4 H CH3 CH2O O O CH3 H O Catalyst Selection (1) Based on knowledge of catalyst materials (1) Mild dehydrogenating catalysts Usually oxide catalysts, metals are strong DH catalyst Cu2+, Ni2+, Fe3+, Mn2+, V3+, V5+, Ti4+ (2) Mild oxidation catalysts Sc3+, Ti4+, V3+, Cr3+, Fe2+, Zn2+, Zr3+, Nb3+, Mo6+ (3) Low mobility Co3O4 > MnO2 > NiO > CuO > Fe2O3 > Cr2O3 > V2O5 > MoO3 (4) Hard to reduce CoAl2O4, NiAl2O4, ZnTiO4 Bond G.C. Catalysis by Metals, Academic Press (1962) Krylov O.V. Catalysis by Non-metals, Academic Press (1970) Propose a Catalyst Mild DH Fe3+ V3+ V5+ Ti4+ Mild OI Sc3+ V3+ Ti4+ Fe2+ Zn2+ Zr3+ Nb3+ Mo6+ Possible Catalysts Single TiO2, V2O3 Mixed TiO2 + MoO3 V2O3 + ZnO Complex Fe2O3 Zn TiO3 Catalyst Preparation (1) Unsupported Catalyst are typically usually very active catalyst that do not require high surface area e.g., Iron catalyst for ammonia production are usually used for high temperature applications e.g., refractory aluminates for catalytic combustion intrinsically have a large surface area e.g., gamma alumina catalyst for isomerization clay catalyst for hydrogenation (2) Supported Catalyst requires a high surface area support to disperse the primary catalyst, the support may also act as a co-catalyst or secondary catalyst for the reaction Unsupported Catalyst Typical preparation methods Unsupported Catalyst Required preparation steps Unsupported Catalyst Typical preparation methods (1) Fusion Method Unsupported Catalyst Typical preparation methods (2) Precipitation and Co-precipitation Methods Unsupported Catalyst (2) Precipitation and Co-precipitation Methods Unsupported Catalyst (2) Precipitation and Co-precipitation Methods Preparation of aluminum oxide Unsupported Catalyst Typical preparation methods (3) Sol-gel synthesis Unsupported Catalyst Typical preparation methods (3) Sol-gel synthesis Silica-alumina acid catalyst Unsupported Catalyst Sol-gel Chemistry 1. 2. 3. 4. 5. 6. 7. 8. Synthesis pH Temperature Reaction time Reagent concentration Nature and amount of catalyst H2O/M ratio Aging temperature and time Drying conditions Sol-gel Chemistry Hydrolysis 1. Synthesis pH Nucleophilic attack Sol-gel Chemistry Hydrolysis 2. Nature and Amount of Catalyst Acid Catalysts Strong Acids: Mineral Acids (HCl) Weak Acids: Organic Acids (Acetic Acid) Rate of Hydrolysis [Acid] Sol-gel Chemistry Hydrolysis 2. Nature and Amount of Catalyst Base Catalysts Strong Bases: Mineral Bases (NH3) Weak Bases: Organic Bases (Amines) Rate of Hydrolysis [Acid]1 or 2 Sol-gel Chemistry Hydrolysis 3. H2O/Si Ratio Acid Catalysts Rate of Hydrolysis [Water]1 Basic Catalysts Rate of Hydrolysis [Water]0 Sol-gel Chemistry Condensation 1. Synthesis pH Sol-gel Chemistry Condensation 2. Nature and Amount of Catalyst Unsupported Catalyst Typical preparation methods (4) Frame Pyrolysis Fumed silica (a) vaporizer (b) mixing chamber (c) burner (d) cooling section (e) separation (f) deacidification (g) hopper (h) compactor Frame Pyrolysis (Fumed Silica) (a) 380 m2g-1 (b) 300 (c) 200 (d) 90 Supported Catalyst Maintains large catalyst surface area and prevents sintering during high temperature operation Supported Catalyst Typical support materials Support Materials Metal Ion Distribution in Support Pellet Supported Catalyst Weak Interaction Interaction Catalyst-Support Interactions Supported phase-support interaction (transition layer attachment) Monolayer formation Bilayer formation Catalyst-Support Interactions Formation of solid solution Formation of new compounds Grafted catalyst Supported Catalyst Typical preparation methods (1) Precipitation method Precipitation Method