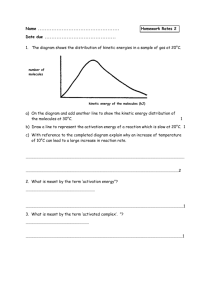

Kinetic model

advertisement

Data Update ---------------Transesterification of triglyceride with methanol at different temperatures Shuli Yan 20080205 1 Outline Introduction Homogenous catalysis Heterogeneous catalysis Experiment Catalyst structure Effect of temperature on methyl esters formation Kinetics of soybean oil to methyl esters 2 Introduction Transesterification of vegetable oil with alcohol for biodiesel production Homogeneous catalysis Strong acid or alkaline catalysts such as HCl, NaOH Heterogeneous catalysis 3 Introduction Kinetics of transesterification catalyzed by homogenous catalysts Dufek studied the kinetics of acid-catalyzed transesterication of 9(10)carboxystearic acid and its mono- and di-methyl esters. Freedman et al. firstly reported transesterication reaction of soybean oil and other vegetable oils with alcohols, and examined in their study were the effects of the type of alcohol, molar ratio, type and amount of catalyst and reaction temperature on rate constants and kinetic order. Noureddin and Zhu studied the effects of mixing of soybean oil with methanol on its kinetics model of transesterication. 4 Introduction Kinetics of transesterification catalyzed by heterogonous catalysts very little information concerning the kinetics of heterogeneously catalytic transesterification Our goal: 1. studying the use of the heterogeneously ZnxLayOz catalyzed transesterification reaction in batch stirred tank reactors for biodiesel production 2. developing a kinetic model based on a three step ‘Eley–Rideal’ type mechanism to simulate the transesetrification process. 5 Experiments Catalyst preparation and characterization Homogeneous-coprecipitation method using urea as precipitant 1. Prepare a mixture solution of Zn(NO3)2 , La(NO3)3 and urea 2. Heat to 100 oC and hold for 6 hr 3. Stirred with magnetic stirrer 4. Filter/unfilter 5. Dry at 150 oC for 8 hr 6. Use step-rise calcination method at 250 (2hr), 300 (2hr), 350 (2hr), 400 (2hr), 450 oC (8hr), SEM/EDS 6 Experiments Transesterification Molar ratio of methanol to soybean oil-----------------42:1 Catalyst dosage---------------------2.3 %(wt) Stir speed-----------------------------490 rpm 7 Catalyst structure SEM/EDS 8 Catalyst structure SEM/EDS 9 10 Catalyst structure SEM/EDS 11 Catalyst structure SEM/EDS 12 Effect of temperature on methyl esters formation Reaction conditions: 50 ZnxLayOz Yield of FAME % 40 ZnxLayOz, catalyst dosage is 2.3% (wt), 30 20 Blank 10 Molar ratio of methanol to oil is 42:1, Stir speed is about 490 rpm 0 120 140 160 180 Temperature 200 220 240 o C Fig. 5 Methyl esters yield at different temperature Temperature was raised by step method. And when getting to the at target temperature point, it 13 was hold for 1min Effect of temperature on methyl esters formation 100 Reaction conditions: 80 ZnxLayOz, catalyst dosage is 2.3% (wt), 60 o 210 C o Molar ratio of methanol to oil is 42:1, 200 C 40 o 190 C o 180 C 20 stir speed is about 490 rpm. 0 0 100 200 300 400 Time min Fig. 6 Effect the temperature on the methyl esters formation 14 Kinetic model Assumptions: 1. The slurry batch reactor was perfectly mixed 2. Only methanol molecule adsorb on the surface of catalyst — pKa (Methanol: 15.54 Natural oil: 3.55 ) — Molecular size (Methanol: 0.33 nm Natural oil: 2 nm) 3. Surface chemical reaction is the rate-determing step — Heterolytically dissociate 15 Kinetic model Fig. 7 Transesterification reaction 16 Fig. 8 Methanol dissociates heterolytically on acid and base sites of ZnO surface. Kinetic model Eley-Rideal bimolecular surface reactions CA An adsorbed molecule may react directly with an impinging molecule by a collisional mechanism A AB CB B RDS QA khet fast Fig. 9 Eley-Rideal mechanism 17 Kinetic model Elementary reactions based on Eley-Ridealtype mechanism 1. Adsorption A S AS Where A is methanol molecule and S is an adsorption site on the surface N A bAC A N0 (1) Where N A is methanol molecule concentration on the surface of catalyst, bA is the adsorption coefficient, N is the fraction of surface empty sites, CA is the concentration of methanol. 0 18 Kinetic model Elementary reactions based on Eley-Ridealtype mechanism 2. Surface reaction AS B DS C Where B is tri-, di-, and mono-glyceride molecule, DS is an adsorpted di-, and mono-glyceride molecule on catalyst surface, r k2 N A CB k2 N D CC (2) Where k2 and k-2 is the reaction rate constants, Cc is the concentration of FAME 19 Kinetic model Elementary reactions based on Eley-Ridealtype mechanism 3. Desorption DS D S Di-, mono-glyceride and glycerin desorbs from catalyst surface N D bDC D N0 (3) Where N D is di-, mono-glycerie and glycerine molecule concentration on the surface of catalyst, bD is the adsorption coefficient, CD is the concentration of di-, mono-glycerie and glycerine . 20 Kinetic model According to steps 1 , 2 and 3, we can get r k2bAC ACB N 0 k2CC bDCD N 0 Because of Then (4) N S N 0 N A N D N 0 N S 1 bAC A bD C D (5) k 2 N S bAC AC B k 2 N S bD CC C D r 1 bAC A bD C D 21 Kinetic model 1 k C AC B CC C D KP r 1 bAC A bD C D Where k k 2 N S bA (6) KP k 2bA k 2 bD Because tri-, di- mono-glyceride and glycerin have low adsorption, bA C A Then >> bD C D 1 k C AC B CC C D KP r 1 bAC A (7) 22 Kinetic model Because the final product glycerine will separate from reaction mixture, we assume that step 2 is unreversible. r kCA CB 1 bAC A k 2 N S bA CB 1 bA CA (8) When methanol concentration is kept constant, r k r CB Where kr k 2 N S b A 1 bA C (9) 23 Kinetic model The rate constant of transesterification reaction Table 1 the reaction rate constant of transesetrification Reaction condition Temperature oC k(s-1) Pressure Psi 180 ~ 330 0.01299 190 ~ 410 0.01806 200 ~ 450 0.05000 210 ~ 580 0.05220 24 Kinetic model Arrhenius equation E ln k ln A RT -2.7 -3.0 -3.3 Ln k E = 16.4 KJ/mol -3.6 -3.9 -4.2 -4.5 0.0044 0.0046 0.0048 0.0050 0.0052 1/T K 0.0054 0.0056 0.0058 0.0060 -1 Fig. 10 The temperature dependency of the reaction rate constants 25 ZnO ZnOx + ZnOx + O (1) CH3OH Zn(CH 3O) 2 + O H2C O C R1 O HC O C R2 O + O H3 C O CH3 O O Zn CH3 Zn O CH3 (3) HC O C R2 O H2C O C R3 H2C O C - H2C O C R1 O H2C O C R3 R1 (2) H2O O Zn O CH3 (4) O O CH3 + HC O C R2 O H2C O C R3 H 2C O H H2C O Zn O CH3 O H3C OH + HC O C R2 O H 2C O C R 3 O H3 C O O Zn CH3 + (5) HC O C R2 O H 2C O C R 3 Fig. 11 Mechanism of ZnO-catalyzed transesterification of triglyceride with methanol 26 Conclusion A multiporous catalyst 170 oC A kinetic model was developed based on a three-step E-R type of mechanism. First order reaction as a function of the concentration of triglyceride E = 16.37KJ/mol 27 Future work Investigate the influence of some kinetic parameters on transesterification such as molar ratio of methanol to oil, catalyst amount 28 Thank you! 29