Slides

Minerals and Resources

Minerals Versus Rocks

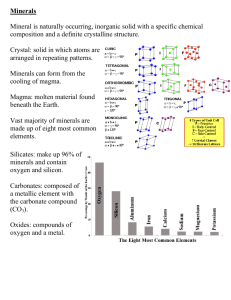

Mineral - any naturally formed, solid chemical element or compound that has a definite composition and crystalline structure

Rock - any natural, solid aggregate material, usually made of minerals

All minerals are rocks, but not all rocks are made of minerals

Quartz Granite

Mineral Properties

•Chemical composition

•Crystalline shape

•Hardness

•Color

•Streak

•Luster

•Cleavage

•Fracture

•Specific Gravity

•Magnetism

These properties are used to identify different minerals

Chemical Composition

Extremely important for the minerals industry. Often want an element or compound in mineral, and not necessarily the mineral itself

Ex.: iron and sulfur from iron pyrite (FeS

2

)

Identifying a mineral by chemical composition requires submitting a sample for chemical analysis; can be time consuming and expensive

Crystalline Shape

Useful for identification; of little use for industry, as crystalline shape can be replicated in lab

Shape normally determined by chemical formula

Jewelry about the only use for this property; even then, the fact that crystals can be artificially created means that their value is artificial, as well

Hope Diamond

Hardness

Mho’s Scale

1 = Talc

2 = Gypsum

3 = Calcite

4 = Fluorite

5 = Apatite

6 = Orthoclase

7 = Quartz

8 = Topaz

9 = Corundum

10 = Diamond

Relative scale based upon what mineral will scratch what mineral

Ex. Orthoclase will scratch apatite, but quartz will scratch orthoclase

Fingernail is about a 2.5; steel nail = 5.5

Diamond is hardest, which means that it does have some industrial application

Hardness does not relate to elemental scarcity or value

Color and Streak

Color - what color unmolested mineral appears to be

Streak - color of ground mineral

These two can be radically different.

Ex.: Iron pyrite color is gold (fool’s gold); streak is black

Hematite is black/gray; streak is red-brown

Color is unreliable as identifier since impurities can change it; streak is more reliable

Other Properties

Depending upon mineral, will use a variety of other identifiers

Magnetism - used to identify iron ores

Cleavage - used to identify minerals like mica and gypsum that form crystals that loosely bond together

Fracture - helps to identify minerals with crystalline shapes that do not cleave

Mineral Types

Based upon the key elements in the chemical composition, minerals are grouped into subcategories

•Silicates (feldspars, garnets, micas, olivine, quartz, clay minerals)

•Native Elements (diamond, sulfur, gold)

•Sulfides (galena, pyrite, millerite, sphalerite)

•Sulfates (barite, celestite, gypsum, secondary sulfates)

•Oxides (goethite, hematite, ilmenite, limonite, uranium minerals)

•Carbonates (calcite, dolomite, other iron-carbonate and others)

•Phosphates (apatite, vivianite, pyromorphite)

•Halides (fluorite, halite)

Silicates

The largest group of minerals (30% of all minerals; 90% of whole crust); defined by having SiO

4 tetrahedra

Includes some gemstones such as tourmaline and topaz

Also has useful minerals such as talc, kaolin, and mica

Rocks made from silicates very useful for road and building materials

Native Elements

Contains all of the metals (gold, silver, copper, etc.) and metal alloys

Also includes diamonds and graphite (carbon)

Rare to find elements in their natural state; oftentimes, a primary method of metal extractions is from some other class

Ex. Copper and lead from sulfide minerals

Strategic Resources

Defn. - resources that a country uses, but cannot produce enough to meet demand

If cannot guarantee supply, economy could be hurt if supplies cut; Ex. OPEC oil embargo of 1973

Wealthy nations try to stockpile surplus to act as buffer against outside forces affecting economy

Vulcan Materials pit mine, Kennesaw, GA, 1993

Mining

Hollywood image of old man with mule, pick axe, and dynamite all but disappeared

Most economic mining done on huge scale with big equipment

•Open pit - dig deep into the ground, exposing new rock to surface

•Stripmining - shallow mine over large area

•Underground mining - tunnels

Open Pit

Mineral ore dug from deep hole created in the surface.

Walls of pit have roads built into them for cranes, trucks, etc. to be able to get to bottom

Economics of recovery have to constantly be re-evaluated, as hole must get wider as go deeper (walls are the road system)

Stripmine

Differs from open pit in horizontal extant

Stripmines are going after near horizontal seam of materials that are near the surface

Overburden is stripped from seam, and then mineral is extracted

Once mineral removed, overburden put back on top

Federal law now requires remediation

Underground Mining

Pickaxe and dynamite have been replaced by large tunneling equipment that does the job safer and faster

Must leave some pillars of material behind, lest a cave-in ensue

Most dangerous form of mining

Miner safety in jeopardy from cave-ins and dust (black lung disease)

Other Techniques

Hydraulic mining - sediments are blasted from hillside with water jets; sediment is sent through sluice boxes; not done much in U.S., but is done many other places (South America)

Dredging - similar to hydraulic mining, with the exception being that the sediment is scooped out of the ground instead of being blasted out with water

Mining Pollution

•Water passing through mine leaches toxic chemicals

•Tailings piles and ponds erode and contain toxics

•Processing chemicals are toxic and sometimes released

•Land slumpage when cave-ins occur

•Underground fires can burn for decades

•Many mines are abandoned when economics fail

•Energy used for entire process is large

Pictures from Berkeley Pit in Butte Montana

Superfund Sites

Processing

Some rocks and minerals take very little processing

Ex: crushed rock for roads and construction material

Others take an incredible amount of energy and produce great quantities of waste

Smelting - heating metal ores to extreme temperature to release metal; gaseous vapors are toxic and often acidic

Leach extraction - pour acid or base on crushed piles of ore, extract metal from leachate by electrolysis; crushed ore is left to contaminate water supply when finished, with acid or base still present

Recycling

•Besides saving environmental damage for extraction and processing, can save huge quantities of energy

•Recycling aluminum saves 95%

•Recycling glass saves 25%

•Recycling steel saves between 60-75%

•Recycling plastic saves 33% of the energy needed to make them from virgin materials

Recycling just one aluminum can will save enough energy to run a 100W lightbulb for 20 hours