Titre de la présentation

advertisement

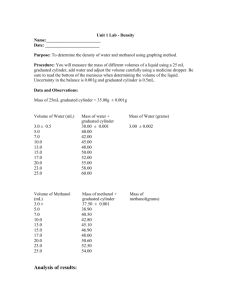

Mini-Methanol Plant Tata MESSIRI Senior Special Assistant (DTSG/OPTS Initiative) to Governor of Delta State, Nigeria Presentation format • • • • • • • • • • What is DTSG/OPTS Initiative? Why methanol? Why small scale methanol? Sustainability and sustainable development Economics of methanol production Methanol production process Small scale methanol plant parameters Multiplier effects associated with methanol Project Partners Next Steps DTSG/OPTS Initiative • DTSG-Delta State Government • OPTS-Oil Producers Trade Section of the Lagos Chambers of Commerce • INITIATIVE=To bring about sustained and sustainable livelihoods for the people in the Delta State Why Methanol? ESTIMATED CAPITAL COST, GAS INPUT AND REVENUE GENERATION FOR PROPOSED PRODUCTION UNITS IN INDUSTRIAL ESTATE CLOSE TO OIL FIELDS ANNUAL GAS INPUT S/ N 1 PLANT LPG Plant ESTIMATED PLANT COST ($ MILLION 25 QTY (BILLI ON SCF) bscf 20.00 COST OF GAS($/ SCF) 0.25 COST ($ MILLIO N) 5.000 ANNUAL OUTPUTS PRODUCTS LPG (12.17%) Dry gas (85.10%) Condensate (1.61%) UNIT PRODUCT UNIT COSTS ($) 142,930 tonnes 150 21.440 17,000,000 000scf 0.5 8.500 bbls 20 6.008 QTY 300,400 PRODUCT VALUE ($ MILLION) RATIO PRODUCT VALUE TO GAS INPUT 7 2 Methanol 20 1.13 0.50 0.565 Methanol 32,000 tonnes 180 5.760 10 3 Ammonia 25 1.05 0.50 0.525 Ammonia 32,000 tonnes 200 6.400 12 4 Ammonia/ Urea Complex 45 1.05 0.50 0.525 Urea 55,680 tonnes 200 11.136 21 Carbon black 40,000 tonnes 1,000 40.000 80 2.40 0.50 5 Carbon Black 1.200 Hydrogen 5 33 bscf Energy 6 7 8 9 Direct Reduced Iron (DRI) Bio proteins 225 45 6.73 0.90 Cassava Starch, ethanol, methanol Power generation (50 MW) 0.50 0.50 3.365 0.450 DRI 600,000 tonnes 120 72.000 10,000 tonnes 1,000 10.000 22 MWh 50 21.900 12 21 Off gases Bio proteins Cassava 0.50 25 3.74 0.50 - 1.870 Starch Electrical Power 438,000 Why small scale methanol? • It takes about 8years for permitting and construction of a large world scale methanol plant. A small scale methanol plant can be up and running in about 2 years. • The agitation and unrest in the Niger Delta will not wait to be resolved in 8years time. • Moreover, several small scale plants will employ more people than one large scale plant. • Small methanol plants are less sophisticated and therefore more appropriate for developing countries • However, there is a problem today for small oil fields in Delta (250 or more), some of which have to install gathering lines for associated natural gas at prohibitive cost. These fields with small natural gas (only 4mmSCFD) can support a 100tonne/day methanol production plant. • If a small plant were to have favorable financing and low-cost gas, it could in fact be competitive with the large plants in a local fuel market. Sustainability and Sustainable development • Sustainable Development – Helping mitigate CO2 emissions (global environment) – Improving health & standards of living, reducing poverty (social pillar) – Increasing local employment and productive use (economic pillar) – Reducing deforestation and improving indoor air quality (local environment) – Energy interacts with people’s lives in many different ways, from the basic survival activities to increasing productivity. – Productivity can be increased by extending the working day with lighting and by mechanization. – It can free up their time, improve their health and well-being, and open up opportunities. – Energy services can contribute in a number of ways to the efficient performance of healthcare delivery system, for example, through ensuring reliable heating, lighting, sterilization and refrigeration, as well as safe disposal of medical waste. – Use of biomass fuels for cooking and space heating creates indoor air pollution, which has been linked with increased rates of acute respiratory tract infection (ARI) in children • Why can methanol be the bridge to sustainability? – Methanol can be made at low cost from natural gas – There is enough flared gas in Nigeria to supply every family in Sub-Saharan Africa with methanol for cooking fuel. – Methanol is a splendid cooking fuel, and there has been in use for decades a very efficient stove in which to burn it. – Methanol can eventually be made from biomass by known technology when we learn to produce enough biomass sustainably at low cost. – Methanol is a nearly ideal fuel in internal combustion engines or for fuel cells, and an equally ideal fuel to replace the still enormous consumption of wood as a cooking fuel in developing countries. – Its use will eliminate the smoke and soot produced in the household when wood is burned, and will reduce household CO2 and greenhouse gas (GHG) production by about 5/6 when compared to using non-replaced forests for fuel. – It is also very attractive as a replacement for the more expensive and valuable kerosene, which has enormous liabilities as a household fuel. – It is handled as a liquid but burns as a gas – It does not require expensive cylinders and regulators to be deployed. Biomass vs. Commercial Energy in Nigerian and Sub Saharan Africa Biomass(mtoe) Oil Products(mtoe) Electricity(mtoe) Biomass(%) O ilProducts(%) Electricity(%) Nigeria 60,212 866 834 Sub Saharan Africa (12) 114,043 2,016 1,710 Source: IEA: Energy Statistics and Balances of Non-OECD Countries, 1997 (1999 Edition) 97.3 96.8 1.4 1.7 1.3 1.5 Economics of Methanol production Projected Plant Price for Current 5000 tpd Plants Under Construction Capital Battery limits ($233/annual ton) $384,000,000 Off Sites (58/annual ton) 96,000,000 Total ($291/annual ton) $480,000,000 Plant Price $/ton Capital charge Feed and Fuel Plant operating and maint. Selling & Admin Total Plant Price ¢/gal 50.6 8.3 16.7 1.7 77.3 ¢/liter 15.2 2.5 5.0 0.5 23.2 4.0 0.66 1.32 .13 6.11 This plant price assumes 330 days per year operation at full capacity. Capital charges are based on 30% equity, 70% loan at 10% interest per annum payable over 10 years (usual commercial rates). A more likely scenario would be 80% of the above assumed capacity This raises the plant price to $94 per ton (28 cents/gal, or 7.4 cents/liter). This is at the plant gate. If cognizance is taken for transportation from far from small users and repackaging into small lots, we arrive at cost closer to twice this amount say 56¢ and over per liter. This costs we already have where refined petroleum products are costing 2 – 3 times in the riverine areas what it costs in the urban centers. Projected cost for methanol from modular plants ¢/gallon ¢/liter Salaries 2.0 0.5 Feed and Fuel 3.1 0.8 Purchased Power 0.1 0.0 Catalyst and Chemicals 0.9 0.2 Maintenance on Plant 4.9 1.3 Raw Water 0.1 0.0 Insurance and Taxes 1.7 0.5 Capital Charges 23.8 6.3 Total 36.6 $/ton 6.7 10.3 0.3 3.0 16.3 0.3 5.7 79.3 122.0 Small scale plant is built on a modular skid mounted basis and so does not obey the 0.67 capacity factor rule but is in fact about 67% of what using the 0.67 factor rule would have cost. Capital charges assume 30% equity, 70% loan at 8% interest per annum payable over 15 years. This is a leveraged loan through multilateral aid organizations, GGFR or other mechanism. Even at this capital charges are still about 150% that for a large scale plant. When transportation fees and lower than100% capacity utilization is taken into consideration, price to consumer would be between 40¢ and 70¢ per gallon or 10¢ to 18¢ per liter. Methanol Production Process • 25-100 TPD Hydrocarbon Feed Feed Pretreatment Steam Reforming and Heat Recovery Methanol Product Methanol Distillation Methanol Synthesis Cooling and Compression Small scale methanol plant parameters • Process – Desulfurization of natural gas – Catalytic Steam/Hydrocarbon Reforming – Heat Recovery from Process Gas – Synthesis Gas Compression – Synthesis Gas Loop – Methanol Distillation • Units – Reforming System and Heat Recovery – Methanol Synthesis Loop – Methanol Distillation – Offsites • Feed – Natural gas composition – – – – Methane Sulfur LHV HHV 79.62%(v) approx. 10ppm(v) max 9,104kcal/ncm 10,054kcal/ncm • Product – methanol composition – Methanol 99.85%(wt) min. – Water content 0.5%(wt) max. – Specific gravity 0.7885 max • Utilities requirements – – – – Natural gas 1,008 ncm/mt Raw water 2,069 kg/mt Nitrogen(startup)75ncm/hr for 8hrs Electrical power 552 kwh/mt Methanol fuelled absorption cooling Methanol fuelled lantern Methanol fuelled cookstove Methanol fuelled microturbine Deforestation can be arrested by the use of methanol cookstoves Flaring reduced from conversion of associated gas to methanol Power generation can be fuelled with readily available methanol Agro-processing can be increased from availability of commercial energy Methanol in our lives Desirability of small scale methanol processing for oil producing areas in Nigeria • • • • • • • Methanol can be in made in small scale modular plants from stranded flared gas that would be difficult or uneconomical to transport for processing to LNG or other facilities by pipeline thereby achieving faster flare down Methanol burns as efficiently as a liquefied petroleum gas Methanol would be cheaper to produce and is more available than kerosene Methanol is soluble in water and therefore easy to extinguish in households Methanol is easier to transport and market than liquefied petroleum gas; and does not require pipeline infrastructure like natural gas Methanol will therefore act as a replacement for both wood and liquefied petroleum gas Methanol can be mixed with ethanol to achieve the ongoing Federal Government initiative to link rural development to the energy sector • • • • • • • • 100t/d methanol plant will provide cooking energy for 125,000 families Each 100t/d methanol plant will mop up 4mmcfd of flared gas 100t/d methanol plant will prevent the cutting of 500t/day of wood, replace about 100t/day of kerosene or liquefied petroleum gas. Methanol availability and use will improve productivity in the rural areas where over 70% of our population live. Methanol use as a household fuel will improve indoor air quality, reduce deforestation and reduce flaring. Nigeria with a population in excess of 120 million can accommodate 200 nos 100t/d plants. There are over 250 small oilfields in the Niger Delta and this is an opportunity to generate economic activity and employment in these communities. The fuel methanol industry will improve power availability through micro and mini power generation Methanol availability will jumpstart the chemical industry based on methanolformaldehyde, synthetic glues, acetic acid, vinyl acetate, etc. Project Partners • Delta State Government, through its Ministry of Power and Energy • Bayelsa State Government • Centre for Household Energy and Environment (CEHEEN), a Delta region NGO specializing in stoves and household energy • Local business interests – – – – – Methanol production Stove production Lantern production Refrigerator production Internal combustion engine modification • Dometic AB, a Swedish company, alcohol stove and appliance manufacturer • HydroChem, a Division of Linde AG and producer of small-scale gas synthesis equipment • SASOL Chemicals, a producer of synthetic ethanol and methanol in South Africa • The United States Environmental Protection Agency (USEPA) "Partners for Clean Indoor Air" (PCIA) • United Statas Agency for International Development (US AID) Preliminary indications from pilot study • LOW-/MEDIUM-INCOME SECTORS – Kerosene will be displaced because it is more expensive, less efficient, indoor air quality is impaired when used, etc. – Fuel wood will also be displaced because of its convenience, better indoor air quality. – Price of the stove and fuel will be a deterrent. – Use of micro-credit could offset this deterrent. – CERs can play a decisive role and it would be innovative with consumers being the actual beneficiaries of their savings to the climate • HIGH INCOME SECTOR – LPG will be displaced because of unavailability of product and disadvantages associated with packaging in heavy pressurized cylinders. – Electric cookers will also be displaced because of regular and unpredictable power outages. – Cost is not an issue. – If a CDM methodology can be developed CERs due from the project can be applied for the purchase of stoves for low income users. Next Steps: • The GGFR Initiative should support WIN-WIN scenarios related to the 3 pillars of sustainable development – economic, social, environment. • Developing small-scale use of methanol at local / regional level will take advantage from use of flared gas, – helping mitigate CO2 emissions (global environment) while – improving health & standards of living, reducing poverty (social pillar) – increasing local employment and productive use (economic pillar) – reducing deforestation and indoor air pollution (local environment) • Economic empowerment of the oil producing communities will reduce the unrest and restiveness thereby improving operating profits and image of IOCs and government • Sign MOU with all Methanol Alliance parties • Carry out detailed feasibility studies and business plan • Identify stranded associated gas fields • Put in place political and other necessary risk guarantees • Match local and international investors and partners • Develop a CDM Methodology for the project • Develop a micro-credit scheme for the financing of purchase of the stoves • Need support from GGFR partners active in Nigeria – – – – Federal Government of Nigeria Shell Petroleum Development Co. ChevronTexaco World Bank/IFC