The Global Economy

The Global Economy

Global Economy

• Common to buy clothing anywhere in US which has a tag labeled, ‘Made in Malaysia, China or

Sri Lanka’

• Simple observation reminds us that our consumption of goods has a strong international character

• Increasingly true to speak not only of national economies but a larger, highly inter-connected and interdependent- GLOBAL ECONOMY

• Before discussing basic mechanisms of industrialization and economic change within

Third World, important to look at the broader global industrial environment within which these nations are forced to compete

Setting the Stage: Origins of the Global

Economy

• Since 1970s world economy hit by turbulent forces

• Unemployment in western countries

• Traditional industries (iron and steel) have declined

• LDCs bearing huge financial debts which threaten drive for development

• Trading tensions have emerged between industrial countries and the newly industrializing countries

Causes of These Conditions?

• Some argue that continuing OPEC escalation of oil prices through limited production is root cause

• Had some effect but too simple an answer

• More profound changes in world economic structure were underway before this

• Increasingly growing consensus that world economy has become more volatile, complex and tightly connected

• Countries affected by what is happening abroad and at larger geographical scale

Internationalization of Trade and Labor

• As with Japanese autos, American computers and Taiwanese calculators there is an emergence of a “new international division of labor”

• Basically a change in geographical pattern of specialization at the global scaleconstantly changing and very dynamic

• Example: movement of textile and shoe production from Indonesia to China

International Division of Labor

• Division of labor has taken on spatial dimensions- some areas come to specialize in certain types of economic activity

• At broad scale : industrialized countries -- manufactured goods while non-industrialized countries -- raw materials

• However this simple pattern no longer exists

• Now much more complex structure involving fragmentation of many processes and their geographical relocation on a global scale

Forces Surrounding Global System of

Production

• These five factors are affecting production patterns:

• 1. Trans-national or multi-national corporations (MNCs)-firms that operate in many nations

• Increasingly these firms have local production points and suppliers that operate across national boundaries providing and securing labor, capital and other resources from a variety of places and which have become very powerful and important influences in the global economy

Sequential Model of TNC Development

• Stage I- Serve domestic market only

• Stage II- Export to overseas markets through independent channels (sales agents)

• Stage III- Establish sales outlets in overseas markets by acquiring local firm and/or setting up new facility

• Stage IV- Establish production facility overseas by acquiring local firm and/or setting up new facility

Geographical Growth of a Multinational

Corporation

1 2

Nation

Center

Factory

Distribution center

Representative

3 4

Forces Surrounding Global System of

Production

• 2. National governmentsthrough their industrial, trade and foreign policies especially liberalization policies

• Liberalization refers to the way in which policies facilitate transactions (trade and sales) of a variety of products and services

• Deregulation refers to the easing of taxation, entry and pricing of products or services dictated by government policy

• Privatization refers to the ownership of former public sector operations and firms by private corporations and enterprises

Forces Surrounding Global System of

Production

• 3. Enabling Technologiestransport, communications, production and organizational improvements

• Explosion of enhanced transport and communication services such as air cargo, integrators offering definite time delivery (FedEx and UPS), electronic mail and electronic data interchange (EDI)

• Advanced inventory management such (just-intime (JIT)) and new systems of distribution such as third party logistics (3PL)

Just-in-Time and its Logistic

Delivery units for parts

Production Unit

Delivery units for finished goods

Moving storage units

Old warehouse before

Just-in-Time

FACTORY

Assembly Line

Assembly and warehousing place

Moving storage units

25

20

15

10

5

0

50

45

40

35

30

% of Products Shipped for “Just-in-Time”

Manufacturing

1990 1994 1996 1998 2000

Forces Surrounding Global System of

Production

• 4. Shifts in Market Conditions and Demand

• Economic cycles affect markets and production, e.g. the Asian financial crisis

• Dramatic shifts in demand affect over time influence type of good being produced and production schedules

• Application of new technology can mean product obsolescence

• These changes can be described in part through product life cycle

Product Life Cycle

• Essence of PLC is that growth in sales of product follows systematic path, from initial introduction to market through development, growth, maturity, decline and obsolescence

Product Life Cycle

Competition Monopoly

Idea Promotion

Research and development

Stage 1

First competitors

Growth

Stage 2

Mass production

Maturity

Stage 3

Decline of production

Decline

Stage 4

Cellular Phones of Nokia

• Evolution of basic Cellular phones are an example of a product which is especially applicable to the notion of the product life cycle

• phone to color enhancement to camera and email device

Space

Time

Global Financial Centers

Telecommunications

Los Angeles

London

New York

Singapore

Tokyo

Hong Kong

Stock Market Opening Period

Global Production Chains and Networks

• Production Chain: Materials >

Procurement > Transformation >

Marketing and Sales >Distribution >

Service

• Definition : transactionally linked sequence of functions where each stage adds value to the process of goods and services production

• Two aspects important: coordination and regulation and geographical configuration

• Production chains may be very localized but increasingly are global in scale to take advantage of international division of labor

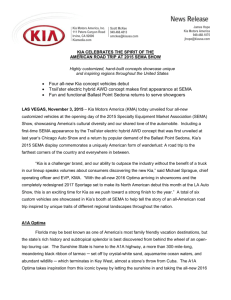

KIA Auto Parts Flow

• Assembled in S Korea KIA Sorrento clear example of global supply chain

• Uses 30K parts from all around world

• Parts shipped from places as diverse as

Wales and Mexico —but very risky

• War in Iraq and piracy in Malacca Straits

• Demonstrate surprising adaptability due to advance planning, multiple sourcing of parts and ability to shift routes on short notice

KIA Auto Parts Flow

• Communicates regularly with suppliers-at least once a week

• Order several months in advance

• If necessary use air freight instead of sea freight

• Greater demand forced KIA to air freight airbags from Swedish company which makes them in the U.S.

• Greater expense of trans-Pacific flight better than slowing down production line