Lead in Construction

advertisement

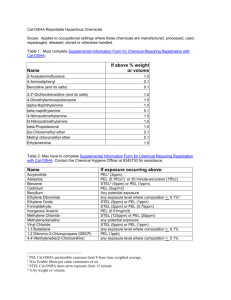

29 CFR 1910.1025 Lead in General Industry 1926.62 Lead in Construction Shaheen Safiullah ile, Compliance Officer Utah OSHA – (801)530Compliance Assistance Specialist 6901 Health Effects • Routes of Entry • Inhalation (breathing) • Ingestion (swallowing) Health Effects • Acute effects – – – – – – – – Abdominal pain Constipation Limb pain Hypertension Vomiting Coma Respiratory arrest Death Health Effects (contd) • Chronic effects – – – – – – Fatigue Weight loss Insomnia Shaking of arms Foot drop, wrist drop Blue line on gums Organs and systems affected • • • • Blood System (heme-synthesis inhibition) Nervous System Kidneys and Liver Reproductive System * Children and Lead Medical Expenses • Higher workers compensation premium – – – – – – – Liability Lawsuits Loss of Productivity Loss in earning power Lost time by supervision Lost time by fellow workers Cost of training new personnel Economic loss to injured worker’s family Exposure Limits • PEL (permissible exposure limit) – 50g/m3 (8-hour time weighted average) – OR, Allowable employee exposure in g/m3) = 400 divided by the number of hours worked in the day • AL (Action Level) – 30g/m3 (8 hour time weighted average) • Blood Lead Level (BLL) – 50 g/dl Exposure Assessment • Employers shall initially determine if any employee may be exposed to lead at or above the action level. Do not use the protection factor of respirators during exposure assessment. – Collect personal samples representative of a full shift • At least one sample for each job classification in each work area with the highest exposure – Exception: Any data obtained within the past 12 months under closely resembling work conditions such as processes, type of material, control methods, work practices, environmental conditions, is acceptable in place of personal air samples in the current workplace. Construction: Provide Protection During Exposure Assessment • Appropriate respiratory protection • Protective work clothing & equipment • Change areas • Handwashing facilities • Training • Initial medical surveillance: BLL Construction: Assumed Exposures >PEL but < 10X PEL • • • • Manual scraping/sanding Heat gun applications General clean up Power tool cleaning w/dust collection systems • Spray painting with lead-based paint Construction: Assumed Exposures >10X PEL but <50X PEL • Lead-containing mortar; lead burning • Rivet busting • Power tool cleaning w/out dust collection systems • Clean up of dry expendable abrasives • Abrasive blasting enclosure Construction: Assumed Exposures >50X PEL • Abrasive blasting • Welding • Cutting • Torch burning Basis of initial determination • Employer shall conduct initial monitoring based on the following observations: – Employee exposure monitoring results – Any information, observations or calculations which would indicate lead exposure – Previous monitoring – Employee complaints of symptoms related to lead exposure Initial determination exception • Objective data showing that a particular product containing lead or a process, operation or activity involving lead cannot result in employee exposure to lead at or above the action level during processing, use or handling, the employer may rely upon such data instead of implementing initial monitoring. – Maintain an accurate record documenting the nature and relevancy of objective data. This record must be maintained for 30 years. • Any data obtained within the past 12 months under closely resembling conditions. • Objective data cannot be used for exposure assessment during interim protection. Positive initial determination • If there is possibility of exposure above the action level then representative monitoring must be conducted. – If above the AL but below the PEL monitoring shall be done every 6 months – If above the PEL then every 3 months Additional Exposure Assessments Required When • Changes that may result in increased exposure: –Equipment –Process/new task –Control –Personnel (e) Methods of compliance Hierarchy of Controls • Goal: reduce exposures to PEL • Must institute engineering and work practice controls • May use administrative controls • May supplement with respiratory protection after achieving lowest feasible level Compliance Program • Required if PEL • Revised/updated every 6 months Compliance Program Components • Description of lead-emitting processes – Equipment, material, controls, crew size, job description, SOPs, maintenance procedures • How compliance will be achieved • Technology considered to achieve PEL • Air monitoring data documenting lead emission source • Schedule for implementation Compliance Program Components (cont’d) • Work practice program – Protective clothing – Housekeeping – Hygiene facilities – Work practices as described in App B where relevant Compliance Program Components (cont’d) • Administrative controls – Implement a job rotation schedule: • ID of employee • Duration and exposure levels of each job • Any other information useful in assessing reliability of administrative controls Compliance Program Components (cont’d) • Arrangements made among contractors on multi-contractor sites (1926.16) • Provisions for frequent and regular inspections of job sites, materials and equipment by a competent person • Revise the program at least every six months No Apparent Controls for Lead Exposure Engineering Control Isolation / Containment Engineering Controls Shrouded Tools w/HEPA vacuum Other Engineering & Work Practice Controls • Substitution • Ventilation • Processes than minimize dust generation – Chemical paint strippers – Wet methods Chemical Paint Removers (f) Respiratory Protection Implement a written respiratory protection program (29 CFR 1910.134) Air-Purifying Respirator (APR) Cleanses the contaminated atmosphere Can’t be worn: in unknown/IDLH atmospheres where prohibited Powered Air-Purifying Respirator (PAPR) An air-purifying respirator that uses a blower to force the ambient air through air-purifying elements to the inlet covering. Atmosphere-Supplying Respirators • Supplies breathing air • Includes: – Supplied air respirators – SCBA – Combination SAR / SCBA units Two Basic Classes of Contaminants • Aerosols/particulates –Airborne solid or liquid particles –Dusts, fumes, mists, fog, smoke, fibers • Gases/Vapors High Efficiency Particulate Air Filter (HEPA) Filter that is at least 99.97% efficient in removing monodisperse particles of 0.3 micrometers in diameter. Equivalent NIOSH 42 CFR 84 particulate filters are the N100, R100, and P100 filters. Medical Evaluations • Before fit testing and use • Performed by PLHCP –medical questionnaire - 1910.134 Appendix C –an initial medical examination Fit Testing Assess respirator fit prior to use Use of Respirators Facepiece Seal Protection • No facial hair or any condition that interferes with the face-to-facepiece seal or valve function • Corrective glasses or goggles or other PPE must be worn in a manner that does not interfere with the face-to-facepiece seal • User seal check each time User Seal Check An action conducted by the respirator user to determine if the respirator is properly seated to the face. Positive Pressure Check Negative Pressure Check Maintenance and Care • Clean and disinfect • Storage – Cartridges/filters separately – Plastic bags or coffee cans Respirator Selection • Based on exposure level • Select using Table 1 • PAPRs must be provided if –Employee chooses and –Provides adequate protection (g) Protective Work Clothing and Equipment Provision and Use • Prevent employee contamination • Provide and maintain at no cost when – > PEL – Skin/eye irritation – Interim protection • Ensure use Cleaning & Replacement • Clean at least weekly; daily if >200g/m3 • Remove PPE in change areas only • Put into closed, labeled containers • Inform cleaning personnel in writing (h) Housekeeping – for all exposures! • Keep all surfaces free from lead • Use HEPA filter when vacuuming • Shoveling, dry or wet sweeping used only where vacuuming or an equal method is not effective • Compressed air not allowed unless used with exhaust ventilation system (i) Hygiene Facilities & Practices Lead on Hands & Blood Lead Levels • Positive correlation between lead on hand tested and blood lead levels Hygiene Facilities & Practices • Required when exposure > PEL • No food, drinks, cigs, cosmetics – Wash hands/face prior • Eating facilities/areas: provide – Free from lead – Enter after removing surface Pb dust Signs Required in Areas >PEL Hygiene Facilities & Practices cont • Provide clean change rooms – Separate work and street clothes – Ensure workers don’t wear PPE home • Showers: provide and ensure use when > PEL – If unfeasible, handwashing facilities – Provide cleansing agents and Hygiene Facilities & Practices cont D-Lead Cleaning Products Lead Check Swabs D-Lead Lead Test Kits Spray Solution 1, then Solution 2 Yellow means lead is present (j) Medical Surveillance Medical Surveillance • Biological Monitoring when = or >AL –Blood lead levels (BLL) –Zinc Protoporphyrin (ZPP) • Medical Examinations by licensed physician Medical Surveillance – cont • When =/ > AL for more than 30 days in any consecutive 12 months • No cost to employees, reasonable time and place • Requirements vary according to – Workplace type – Exposure level – BLL level (k) Medical Removal Protection (MRP) 50 g/dl whole blood Temporary Removals • Final medical determination: Any medical finding that the employee has a medical condition increasing risk of material impairment to health from exposure to lead Temporary Removals - cont • Remove from Pb exposures 50 g/dl • Return when two consecutive BLL tests are 40 g/dl whole blood MRP Benefits • Maintain –Normal earnings –Seniority –Other rights and benefits • Benefits continue for up to 18 mos on each occasion (l) Training Requirements • Prior to start of job • At least annually • Extent of training depends on exposure (m) Recordkeeping • Keep for at least 40 years or duration of employment + 20 years (30 yrs construction) – Exposure assessment data – Objective data for monitoring exemption – Medical surveillance ( duration of employment + 30 years, construction) OSHA website • Federal OSHA: Www.osha.gov – Click on “Technical Links” under the outreach section • Utah OSHA: www.uosh.utah.gov • NIOSH: www.cdc.gov/niosh