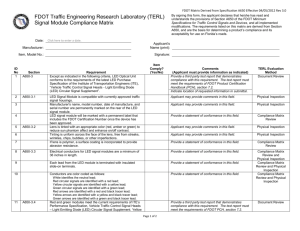

FDOT Matrix Derived from Specification A676 Effective 02/12/2013

advertisement