Construction Management

advertisement

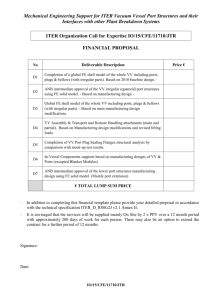

Assembly and Installation Industry Information Day Construction Management Contract by Ken Blackler 21 May 2015 Disclaimer: The views and opinions expressed herein do not necessarily reflect those of the ITER Organization Page 1 Table of Contents: 1. General 2. Scope of Services 3. Description of tasks 4. Interfaces with other contractors 5. Contract 6. Schedule Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 2 Contract Map ITER Organization Construction Manager-as-Agent Machine Assembly Works Mechanical & Piping Works Electrical, I&C Works Specialized Works Super Conducting Joints Domestic Agency Works Contractors Special Techniques MCP ASY Tokamak EIC CMA Lifting & Handling LFT Scaffolding SCF Access, Plant Hire APH Civils & Finishing CIV SPx Balance of Plant Works Contracts Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization Support Contracts IDM UID: XXXXXX Page 3 Construction Management Contract ITER Organization Construction Manager-as-Agent Machine Assembly Works Mechanical & Piping Works Electrical, I&C Works Specialized Works Super Conducting Joints Domestic Agency Works Contractors Special Techniques MCP ASY Tokamak EIC CMA Lifting & Handling LFT Scaffolding SCF Access, Plant Hire APH Civils & Finishing CIV SPx Balance of Plant Works Contracts Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization Support Contracts IDM UID: XXXXXX Page 4 1. General • Purpose: – • Define scope, mission and work activities of the Construction Management-as-Agent (CMA) Contractor. Background: – – – Large and complex worksite Many technical challenges that will arise during the construction Many different actors that must be coordinated in a safe and efficient manner Strong and effective management, combining Tokamak specific knowledge and industrial know-how is required in order to maintain schedule and minimize cost IO Construction Department is responsible to plan, manage and execute the construction works on site of the ITER Tokamak, plant equipment and facilities, and their start-up, testing and commissioning (excluding building construction). Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 5 1. General – ITER Specifics • In-kind Procurement – – • Machine Assembly – – – • Many components are provided ‘free-issue’ by the ITER Member countries through their Domestic Agencies IO-CT and IO-DA manage the supply chain through an integrated team Assembly of the Tokamak is a unique activity where IO has the greater knowledge and must bear the majority of the risks. IO must maintain a strong control of the Machine Assembly activities The CMA shall support IO by supplying the necessary industrial know how, processes and resources. Plant Installation – – – These are conventional works which follow significantly more standard processes CMA shall be involved to a greater extent IO maintains overall responsibility for the priorities and technical performance, management of outstanding issues and interfaces with DAs. Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 6 2. Scope of Services • Services included: – Management • Planning and Program Management • Works Contract Management – Worksite Coordination • Site Coordination • Occupational Health and Safety • Environmental Health and Safety • Material Management – Works Supervision • Supervision of the Works • Quality Control • Record Keeping – Completion Activities • Start-up and Testing • Maintenance Management The Construction Management Contractor shall not self-perform any works. The extent of involvement shall be different for the Tokamak and the Plant Systems. This is a summary only. The complete scope shall be defined in the tender specifications Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 7 3. Description of Services - Management • Planning and Program Management – – – – • Baseline management: Work breakdown structure, scope database, construction schedule and cost Detailed planning, cost estimates, risk analysis of works Report progress, using Earned Value, KPI etc. Administer Requests for Information, Field Changes, Non-Conformances Works Contract Management – – Engineer and/or Assistant to the Engineer for FIDIC contracts; Construction work packages e.g. materials list, drawings, specifications, procedures, equipment and tools, hold points, and quality control documents – Additionally For Tokamak Assembly Works • Field Installation Work Packages - based upon IO supplied Construction Processes, specifications and documentation; • Assembly drawings, based upon sequences, specifications, 3D models and engineering drawings provided by IO. – Additionally For Conventional Works: • Field Installation Work Packages and assignment to contractors This is a summary only. The complete scope shall be defined in the tender specifications Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 8 3. Description of Services – Worksite Coordination • Site Coordination – – – – – • Occupational Health and Safety – – • Support the IO in implementing a continuous improvement safety programme; Manage the Permit to Work system; Environmental Health and Safety – – • Site Rules and Regulations Manage and coordinate activities on the site, space utilisation, traffic, control of pollution and the environment; Access control requests for the worksite; Coordination, steering and planning meetings with IO, DA and works Contractors; Development and implementation of a “pro-rata” account; Ensure that materials used on site do not pose an undue risk to site personnel, nor endanger the environment; Identify and approve any hazardous materials coming onto the ITER site; Material Management – – – Expedite materials by interfacing with IO, DA, suppliers, warehouse and global logistics service provider; Control materials, including receiving, preservation, quarantine and in-field traceability; Administration and operation of the SmartPlant Materials system; This is a summary only. The complete scope shall be defined in the tender specifications Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 9 Construction Worksite Teams Site Construction Manager CMA Overall Daily Site Coordination. Management of Interfaces Worksite Construction Team Worksite Construction Team Worksite Construction Team Worksite Construction Team Worksite Construction Team Worksite Construction Team CMA CMA CMA CMA CMA CMA Electrical Buildings Site Works and Coordination MA Contractor Machine Assembly Works Contractors Tokamak Complex Control Buildings Cooling Water and Cryogenic Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 10 3. Description of Services – Works Supervision • Supervision of the Works – – – – – – Issue instructions to Contractors (within delegated limits and which do not alter the cost of the project); Check applications for payment and assess them prior to IO payment; Manage field engineering processes and information exchange; Assess field change requests, deviation requests and non-conformities. Additionally For Tokamak Assembly Works • Support IO to supervise day works, report technical issues. • Provide independent assessment of field change requests, deviation requests and nonconformities. Additionally For Plant Installation: • Planning, supervision, testing and completion of works within a building, area or room. • manage interfaces, resolve disputes, solve on-site technical issues; • Provide field engineering support to contractors, with expert support from IO. This is a summary only. The complete scope shall be defined in the tender specifications Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 11 3. Description of Services – Works Supervision (2) • Quality Control – – – – – • Check compliance between execution drawings prepared by contractors and drawings and specifications prepared by IO; Assess Contractor’s quality plans and control plans (MIP); Verify conformance of completed works to requirements, specifications and contract deliverables, undertake inspections to confirm; Coordinate and supervise Inspections, Notification and Hold Points; Manage Measuring and Test Equipment including certification, calibration; Record Keeping – – – Manage information, records and documents related to construction within the IO IT environment, including document scanning, classification, filing, searching and printing; Check documentation and ‘as built’ drawings; Support the IO in maintaining complete and accurate records of all site activities. This is a summary only. The complete scope shall be defined in the tender specifications Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 12 3. Description of Services – Completion Activities • Start-up and Testing – – • Working with IO experts, confirm construction activities have been correctly performed. Manage testing performed by the Contractors, IO and DA, record the outcomes, prepare plans for rectification. Maintenance Management – – – Plan and regular, preventative and corrective maintenance for installed equipment; Keep all maintenance associated records; Manage any remedial, corrective and preventive actions. This is a summary only. The complete scope shall be defined in the tender specifications Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 13 4. Interfaces with other contractors • Construction Manager-as-Agent contractor shall interface strongly with all works contracts – – • Act as Engineer/Assistant to Engineer for FIDIC works contracts placed by IO Coordinate works performed by IO and DA contractors Three stages of site coordination – – – Preparation stage - ENGAGE coordination civil construction Early works managed by CMA with overall site coordination by EUDA contractor (ENGAGE) Main works with CMA site coordination Stage 1 • ENGAGE Coordination • No IO Works Stage 2 • ENGAGE Coordination • IO and DA Works Stage 3 • CMA Coordination • IO and DA Works Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 14 5. Information Systems • SmartPlant software suite implemented: – – – – Construction planning and management Materials management Testing Configuration control for construction • System integrated to ensure flow of data, documents from design tools and logistics systems • Customisation by IO to adapt to agreed ways of working (e.g. workflows) • IO will train-the-trainers in the awarded Construction Management contractor Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 15 6. Work Profile • Current schedule is ‘as early as possible’’ – – – – • Uneven profile in resources Logic driven by machine assembly sequences Machine assembly is back-end loaded (mandatory) Plant works early loaded and may be smoothed Work Packages - Not-levelled Tokamak Completion and Hook-ups Specialised works to be reallocated to plant or machine assembly works contracts – Machine Assembly Complete before tenders launched Optimisations will be key to workforce management Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 16 Time Distribution of Works by Domestic Agency Some works shall be transferred to IO for execution Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 17 Time Distribution of IO Works by Contract Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 18 Please send all questions to: assemblyinfoday@iter.org Replies to all questions received within 2 weeks shall be published on the ITER web site and notified to all attendees Assembly and Installation Information Day – 21st May 2015 © 2015, ITER Organization IDM UID: XXXXXX Page 19