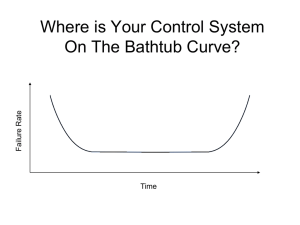

5.3 Dynamic Offset Test Bench

advertisement

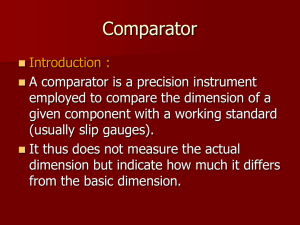

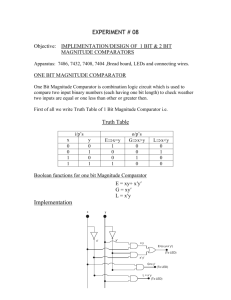

BEHAVIORAL MODELING OF A REGENERATIVE COMPARATOR USING VERILOG-AMS Pranav Kumar Cherupalli B.E., Osmania University, India, 2004 PROJECT Submitted in partial satisfaction of the requirements for the degree of MASTER OF SCIENCE in ELECTRICAL AND ELECTRONIC ENGINEERING at CALIFORNIA STATE UNIVERSITY, SACRAMENTO SPRING 2011 BEHAVIORAL MODELING OF A REGENERATIVE COMPARATOR USING VERILOG-AMS A Project by Pranav Kumar Cherupalli Approved by: __________________________________, Committee Chair Thomas W. Matthews, Ph.D. __________________________________, Second Reader Perry L. Heedley, Ph.D. ____________________________ Date ii Student: Pranav Kumar Cherupalli I certify that this student has met the requirements for format contained in the University format manual, and that this project is suitable for shelving in the Library and credit is to be awarded for the project. ______________________, Graduate Coordinator Preetham B. Kumar, Ph.D. Department of Electrical and Electronic Engineering iii ________________ Date Abstract of BEHAVIORAL MODELING OF A REGENERATIVE COMPARATOR USING VERILOG-AMS by Pranav Kumar Cherupalli Comparators are widely used in mixed-signal systems. They are an essential building block of any analog-to-digital converter architecture. Regenerative comparators are typically used in high-speed analog-to-digital convertor designs. This particular architecture has two main characteristics that make it differentiable from the other architectures. First is the positive feedback during the regenerative phase to achieve high gain and the second is the cancellation of the memory of previous comparison results during the reset phase. A behavioral model of any circuitry block is always helpful, before creating the actual design, to understand the tradeoffs during system design. Verilog-AMS provides an extended capability to model any analog or digital block, so as to seamlessly integrate the behavioral block into the actual design consisting of a combination of analog and digital blocks. A mapping between the analog and digital domains enhances the (re)usability of iv designs for mixed-signal blocks. Since Verilog-AMS actively supports the mixed-signal approach, the interchange of digital and analog blocks is straightforward. This work will result in a behavioral model for a regenerative comparator written in Verilog-AMS. The project presents the behavioral model of a regenerative comparator written in Verilog-AMS. The model is simulated using the time-windowing function to find the sensitivity of the comparator to pre- and post-clock inputs. The key specifications described in [3] by Thomas Matthews will be used to compare Verilog-AMS behavioral model circuit simulation results with analytical results. _______________________, Committee Chair Thomas W. Matthews, Ph.D. _______________________ Date v ACKNOWLEDGEMENTS Behind every achievement lies an unfathomable sea of gratitude to those who actuated it, without whom it would never have come into existence. It is with my deepest gratitude and honor that I convey my thanks to Dr. Thomas W. Matthews, for his exemplary guidance, unending support and for giving me an opportunity to work under his guidance. I am very indebted to Dr. Perry L. Heedley for patiently reviewing my work as the second reader and for providing his valuable support to make this project successful. I would like to extend my gratitude to Dr. Dennis Dahlquist for his guidance and contribution to the project. Special thanks go to Rajdeep Mukhopadhyay of National Semiconductor Corporation for his help during the initial phases of the project. I would like to thank my parents, Venugopal and Mallika, and brother, Hari, who have been a constant source of my energy. Last but not the least; I thank all my friends who implicitly or explicitly helped in the success of this project with their constructive criticism and encouragement. vi TABLE OF CONTENTS Page Acknowledgements ............................................................................................................ vi List of Tables ..................................................................................................................... ix List of Figures ..................................................................................................................... x Chapter 1. INTRODUCTION .......................................................................................................... 1 1.1 Motivation .......................................................................................................... 1 1.2 Regenerative Comparators ................................................................................. 2 1.3 A High-speed CMOS Comparator ..................................................................... 3 1.4 Project Objective ................................................................................................ 4 1.5 Report Organization ........................................................................................... 5 2. VERILOG-AMS MODELING ...................................................................................... 6 2.1 Introduction ........................................................................................................ 6 2.2 Language Basics ................................................................................................. 7 2.3 Model Descriptions ............................................................................................ 8 2.4 Test-bench Design Components ......................................................................... 9 2.4.1 Stimulus Generator ................................................................................ 10 2.4.2 Output Evaluator .................................................................................... 11 2.5 Analog Modeling Development ....................................................................... 11 3. COMPARATORS ........................................................................................................ 13 3.1 Comparators ..................................................................................................... 13 vii 3.2 Linear Model .................................................................................................... 13 3.3 Mathematical Model......................................................................................... 16 4. REGENERATIVE COMPARATOR VERILOG-AMS MODEL ............................... 22 4.1 Macro-Model .................................................................................................... 22 4.2 Voltage Limiting Diodes .................................................................................. 24 4.3 Voltage Controlled Current Source .................................................................. 25 4.4 Input Signal Limiting ....................................................................................... 26 4.5 Tweaking the Model ......................................................................................... 28 5. SIMULATION RESULTS ........................................................................................... 29 5.1 Introduction ...................................................................................................... 29 5.2 Simulation of the Comparator Model ............................................................... 29 5.3 Dynamic Offset Test Bench ............................................................................. 33 5.4 Servo Loop Test Using DOTB ......................................................................... 34 5.5 Simulating the Design ...................................................................................... 37 5.6 Automating the Simulation Environment......................................................... 38 5.7 Interpreting Simulation Results ........................................................................ 39 6. CONCLUSIONS .......................................................................................................... 51 6.1 Accomplishments ............................................................................................. 51 6.2 Future Work ..................................................................................................... 52 Appendix A Source Code for Behavioral Model and Test Bench ................................... 53 Appendix B Verilog-AMS Functions and Operators....................................................... 70 References ......................................................................................................................... 74 viii LIST OF TABLES Page 1. Table 1 Verilog-AMS Built-in Mathematical Functions ............................................ 70 2. Table 2 Verilog-AMS Mathematical Operators ......................................................... 72 3. Table 3 Verilog-AMS Built-in Analog Operators. ..................................................... 72 4. Table 4 Common Verilog-AMS Analog Event Types. .............................................. 73 ix LIST OF FIGURES Page 1. Figure 1.1 Block diagram of a typical Clocked Comparator ........................................ 3 2. Figure 1.2 Schematic of a high-speed CMOS Comparator [7]. The SR Latch is the circuitry on the right with outputs labeled Q and Q-bar. .............................................. 4 3. Figure 2.1 Reference Diode Model and Equation. ....................................................... 9 4. Figure 3.1 Schematic of a typical regenerative comparator. ...................................... 14 5. Figure 3.2 Two cross-coupled current sources represent the cross-coupled latch pair. ..................................................................................................................................... 15 6. Figure 3.3 Model used for practical comparator [3]. .................................................. 17 7. Figure 3.4 Difference-mode half-circuit (τ = RCp )................................................... 17 8. Figure 3.5 Comparator Impulse response and windowing function [3]. .................... 20 9. Figure 4.1 Initial Macro model of a regenerative comparator. ................................... 23 10. Figure 4.3 Regenerative comparator with differential voltage inputs. ....................... 26 11. Figure 4.4 Step response of the model at various clock edges ................................... 27 12. Figure 4.5 Updated Voltage Controlled Current Source (VCCS) schematic, by adding additional diodes and additional pull down resistance. This entire cell replaces the single gm-cell in the Figure 4.3. .................................................................................. 28 13. Figure 5.1 Circuit schematic used for simulation ....................................................... 30 14. Figure 5.2 Simulation of the comparator model with clock rate of 100MHz. ............ 31 15. Figure 5.3 Simulation of the comparator model with clock rate of 10MHz. .............. 32 16. Figure 5.4 Dynamic offset test-bench block diagram. ................................................ 34 17. Figure 5.6 Phase difference between inputs for servo loop test. ................................ 37 x 18. Figure 5.7 Servo loop test simulation reconstructed output after 60 runs. X axis is clock to input phase and Y axis is effective input voltage. ......................................... 38 19. Figure 5.8 Effective inputs at 1 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. ............................................................ 40 20. Figure 5.9 Effective inputs at 10 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. ............................................................ 41 21. Figure 5.10 Effective inputs at 25 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. ............................................................ 42 22. Figure 5.11 Effective inputs at 50 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. ............................................................ 43 23. Figure 5.12 Effective inputs at 80 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. ............................................................ 44 24. Figure 5.13 Effective inputs at 100 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. ...................................................... 45 25. Figure 5.14 Effective inputs at different frequencies obtained from the servo loop test. ..................................................................................................................................... 46 26. Figure 5.15 Magnitude plot using windowing function for the behavioral model. .... 48 27. Figure 5.16 Phase plot using windowing function for the behavioral model. ............ 49 28. Figure 5.17 Magnitude and Phase plots using windowing function for the mathematical model. ................................................................................................... 50 xi 1 Chapter 1 INTRODUCTION 1.1 Motivation Comparators are used in analog-to-digital converters (ADCs), data transmission applications, switching power regulators and many other applications [1]. They are critical components in analog-to-digital converters. Regenerative comparators in particular are important for many high-speed applications, especially Flash ADC’s, where their sampling speed and comparison time are key metrics. In many of these systems it would also be advantageous to simulate an analog system at higher levels of abstraction to understand the different realizations before undertaking the final IC design. Spice is a common computer-aided design tool used to simulate analog or RF circuits. There are three potential drawbacks of using spice in a mixed-signal application. First, a detailed circuit simulation is possible only after the entire circuit is specified. Second, it takes a longer time to simulate, if the circuit gets complex. The last one being, spice requires files specific to the technology being used to fabricate the circuitry that contain very specific information about device behavior. Therefore, the use of spice for circuit simulation requires detailed information that may not be available in the early stages of the design. Verilog-AMS can overcome these problems [2] and provide better design reuse capabilities over other modeling languages. 2 The usage of behavioral modeling for mixed-signal circuit designs has been a topic of research interest [4, 5] because complete transistor-level simulations are often not practical due to the enormous simulation time that would be required [6]. Usage of behavioral modeling lets designers easily explore different system-level architectures at the early design stages and thereby rapidly perform changes to the actual circuit designs. Hence the design of behavioral models reduces the time to market and helps to ensure that the design is likely to perform as desired on the first silicon produced. 1.2 Regenerative Comparators A conceptual block diagram of a clocked comparator is shown in Figure 1.1. A change in the clock state changes the first stage from a stable reset state to an unstable regenerative stage [7]. Hence the clock edge corresponding to the start of the regenerative state initiates the comparison. The digital output is updated and latched when the first stage output reaches a sufficient level to activate R-S latch. The output remains latched until the next comparison is made. If (VP –VN) >0, the output is high or a logical “1” and if (VP – VN) < 0, the output is low or logical 0. Regenerative comparators use positive feedback to accomplish the comparison of two signals. The regenerative comparator is also called the latch because it is bi-stable. The simplest form of latch consists of a cross-coupled MOSFETS with positive feedback, as will be shown in Section 1.3. The operation of latch can be broken down to two modes. The first mode disables the positive feedback and applies the input signals to the drains of 3 cross-coupled MOS devices. The second mode enables the positive feedback and depending on the relative values of inputs, one of the outputs will go high and the other will go low. A two-state clock is used to enable or disable the positive feedback. A second clock phase may be used [7] to control the connection of subsequent stages. The time domain response characteristics of the latch are important to understand the operating speed of the comparator. VN VP S Q R Qb CLK Figure 1.1 Block diagram of a typical Clocked Comparator 1.3 A High-speed CMOS Comparator A high-speed CMOS comparator [7] is shown in Figure 1.2. The comparator consists of three blocks, an input pre-amplifier stage, a regenerative latch stage and SR latch. The architecture uses two non overlapping clocks ф1 and ф2 for the reset and regenerative mode. During the reset mode, when ф2 is high, the transistor M12 is on and the nodes “a” and “b” are connected together by a positive resistance, of M12. During the regeneration mode, after falling edge of ф2, each output “a” and “b” nodes is pulled up to the positive supply or down towards the ground as the small difference established in reset mode 4 regenerates to a full scale voltage. At the end of the regeneration process the SR latch is driven to fully complementary digital outputs based on the regenerative outputs, and remains in that state during the subsequent reset mode. Figure 1.2 Schematic of a high-speed CMOS Comparator [7]. The SR Latch is the circuitry on the right with outputs labeled Q and Q-bar. 1.4 Project Objective The objective of this project is to develop a behavioral model for the regenerative comparator using Verilog-AMS. A model for the comparator will be developed and discussed, and its functionality is verified using the time-window function as presented by Matthews [3]. The implications of the time-windowing function in the frequency domain will be discussed. The model will be developed in Verilog-AMS using a 5 difference mode half-circuit model of regenerative comparator. The dynamic offset test bench [12] will be used to characterize the dynamic offset of the comparator model. The resulting offsets will be compared to an analytical model as a way to verify the performance of the comparator model. Mentor Graphics ® tools will be utilized to simulate the model. 1.5 Report Organization The project report is organized as follows: A brief introduction to Verilog-AMS modeling, followed by the detailed working of a Regenerative Comparator, there upon create a Verilog-AMS model for the regenerative comparator, and finally introducing the reader to Dynamic Offset Test Bench (DOTB) with simulations results using the DOTB and interpretation of simulation results. 6 Chapter 2 VERILOG-AMS MODELING 2.1 Introduction Analog behavioral modeling deals with creating and simulating models based on a desired external circuit behavior. Models can be as complex as necessary to provide the designer with the necessary information on which to base architectural and circuit-level design decisions. Before starting to write a behavioral model, it is important to decide which parameters to model so that the block is not too complicated and yet is useful to evaluate the design tradeoffs. One of the biggest advantages of using modeling is the simulation speed gained by removing transistor-level circuit blocks that are slow to simulate and replacing them with behavioral models that are simpler. Verilog-AMS is the upcoming modeling language for analog and mixed-signal system in this front. AMS stand for Analog and Mixed Signal. Verilog-AMS is the extension of two languages, Verilog-HDL and Verilog-A. It combines the capability of these two languages and adds additional capability to allow the description of mixed-signal components. Hence it’s a true mixed-signal language, interacting with the analog and digital sections by an Application Program Interface (API) between the analog and digital simulators [9]. Verilog-AMS substantially provides strong event-driven constructs and features to create behavioral models for mixed-signal blocks. This is very important, because most of the analog and mixed-signal models used in high level simulations are naturally written using 7 event-driven constructs. Unlike the Verilog digital language, the Verilog-AMS language cannot be used for synthesize analog blocks and will predominantly be used for modeling and verification only. 2.2 Language Basics It is important to understand some of the Verilog-AMS language basics before understanding the modeling features. Verilog-AMS has ability to model a variety of disciplines, the most common of which are electrical, magnetic, thermal, kinetic and rotational [10]. Integrated circuit modeling primarily uses electrical discipline, which is expressed as voltages and currents. The disciplines are defined in a file called “disciplines.vams” which is included during simulation. Apart from the disciplines, there are three basic modeling styles: Conservative, Signal-Flow and Event. Conservative modeling uses both voltage and current to model a system. The Signal-Flow modeling utilizes only voltage (potential) to model systems, typically for high-level modeling where there is no need to express the functionality using current. The third style is Event based modeling, which only evaluates based on events. Verilog-AMS allows any combination of these modeling styles. For this project, we will be utilizing a combination of Conservative and Event modeling style. The syntax of the model file starts with a module declaration with a module name and pin names. Parameter declarations follow, which can be passed from module to module without editing the model file. A branch statement can be used to provide a name to each 8 branch where components share the same nodes. The “analog begin” line is where the analog behavior begins. This is the section where the voltages and currents from outside pins are sensed, checked for signal crossings, mathematically conditioned, then pushed out of the circuit or stored in a file. The Verilog-AMS simulator utilizes a continuoustime kernel to evaluate the analog signals. Practically, this means that every analog signal in the “analog begin” block is executed at every time-step of the simulator, and stops the simulation time until the execution of the step is completed. This limits the language from the usage of ‘delay’ and ‘wait’ statements. The event statements, defined by using ‘@’, have been modified to remove any blocking compared to Verilog-D HDL event statement. 2.3 Model Descriptions The analog behavioral descriptions are mathematical mappings which relate the input signals of the module to the output signals in terms of large-signal, time domain or frequency domain behavioral descriptions. These descriptions use the “contribution operator” <+ to assign values to analog signals [9, 10]. It is important to note that the contribution operator is a concise description of the behavior of the element in terms of its terminal voltages and currents. This simple way of representing the behavior of a nonlinear complex system, is shown for a diode in Figure 2.1. 9 The behavior of the diode can be defined in the Verilog-AMS language as shown in Equation (1), where $vt() is the Verilog-AMS system task that returns the thermal voltage. 𝑖𝑑 = 𝑖𝑠𝑎𝑡 (exp ( 𝑉(𝑛1, 𝑛2) ) − 1.0) 𝑉𝑡 Figure 2.1 Reference Diode Model and Equation. 𝐼(𝑛1, 𝑛2) < + 𝑖𝑠𝑎𝑡 ∗ (exp ( 𝑉(𝑛1, 𝑛2)/$𝑣𝑡() )– 1.0); (1) 2.4 Test-bench Design Components This project also required the development of a test-bench, also using Verilog-AMS components to test the comparator behavioral model. The basic components required to develop any such test-bench are the stimulus generator, the design under test, and the output evaluator. The stimulus generators consist of signal generators, voltage sources, currents sources, resistors and capacitors. The design under test would be the regenerative comparator. The output evaluator would be a model that extracts the needed information from the output node of the design under test and make appropriate changes to the input or flag the user about the output generated. The functionality and purpose of the specific test-bench for this project is further explained in Chapter 5. The design of various blocks 10 that are used in the test-bench, excluding the design under test, will be outlined in the following sections. 2.4.1 Stimulus Generator The stimulus is merely a variable dependent on time, frequency or some other domain depending on the type of design under test being tested. Verilog-AMS stimuli are always a function of time because the Verilog-AMS compiler divides the signal constructed in time steps. The stimulus generators used for this project were a sine wave generator and a clock signal generator. The sine wave generator uses the simple sine wave equation shown in Equation (2). 𝜐 = 𝐴 ∗ 𝑠𝑖𝑛(𝜔 𝑡 + 𝜑 ) (2) Furthermore, to be used as signals in Verilog-AMS, the math function outputs must be passed as voltages or currents to variables that are declared as type electrical. Hence, the Verilog-AMS code for the sine wave generator would look as shown in Equation (3). The equation has variables: “ampl”, “freq”, and “phase”. The equation also has `M_TWO_PI which is a constant value defined with a value equivalent to 2*π, and $abstime is a simulator internal task to define the current simulation time. 𝑉(𝑜𝑢𝑡𝑝𝑢𝑡, 𝐺𝑛𝑑) < + 𝑎𝑚𝑝𝑙 ∗ sin( (`𝑀_𝑇𝑊𝑂_𝑃𝐼 ∗ 𝑓𝑟𝑒𝑞 ∗ $𝑎𝑏𝑠𝑡𝑖𝑚𝑒) + 𝑝ℎ𝑎𝑠𝑒) (3) 11 The clock generator for the test-bench uses a Verilog-D code to generate an always running clock with a parameter value to change the frequency of the clock. Verilog-AMS has several math functions that can be used to easily implement the stimuli. The list of these math functions are presented in APPENDIX B. 2.4.2 Output Evaluator The output evaluator monitors the input and output of the device under test and modifies the input to the device under test when put under a closed loop. The evaluator can also just function as an output information storing point. The output evaluator in the project is a combination of integrator and difference circuit, further discussed in Chapter 5. 2.5 Analog Modeling Development The process of developing a Verilog-AMS behavioral modeling requires a good consideration of how the analog simulator will interpret the model and intuitive understanding of the model. The analog simulators essentially use Newton-Raphson method to solve for non-linear electrical components. If the equations used in the model are not continuous, the simulator may not converge on to a solution. These discontinuities should be anticipated and avoided to minimize non-convergence. When modeling an ideal discontinuity, it is easy to block the regions of discontinuity using the $discontinuity() simulator function. Common desired analog effects such as continuous and smoothly shaped signals can be achieved by carefully studying what is needed and 12 then taking a macro-model approach to creating a model [11]. Modeling can start from a simple top-down functional model to a detailed bottom-up model that closely resembles the transistor circuit. It is also important to consider the limit of simulator time-step and frequency where there are fast transitions (<1pS), or high pole frequencies (>100 GHz). It is possible that just one circuit block with a high frequency oscillation can have a dramatic impact of slowing down the complete simulation. The model should be carefully analyzed and the time-step should be controlled for each block using the $bound_step() simulator function. Threshold detection and time window controls help improving the wave-shaping accuracy. The above said are some of the specifics which caused some trouble in the initial stages of the project. Adding common analog effects like input offsets, delay, rise time, fall time, slew rate, small-signal frequency response, input and output impedance, and signal clipping can help fine-tune to track the output response of the real circuit to that of the model. In addition effects such as Noise, PSRR, Temperature and Process Variation can greatly help the model in various stages during the design phase. But, with complexity, there are simulation time and other tradeoffs. These complexities are not present in this project. 13 Chapter 3 COMPARATORS 3.1 Comparators Comparators essentially compare two analog input voltages, and output a single digital bit that is high or low depending on the relative values of the two input voltages. They can be classified into two major groups, clocked comparators and continuous–time comparators. Continuous-time comparators have no clock input and are essentially high gain differential amplifiers. A clocked comparator, often regenerative in nature, is often used in high-speed data conversion systems. The clock edge corresponding to the start of regeneration is considered to be effectively the time at which the comparator samples the input. It is important to understand, however, that pre- and post-clock inputs do have some effect on the comparator’s output. Rather than sampling at an instant, the comparator is influenced by the input signal during a time window. The comparators time windowing function is determined by its regeneration time constant and its reset time constant [3]. 3.2 Linear Model A Schematic of the first stage of a typical regenerative comparator is shown in Figure 3.1. The MOS latch is composed of n-channel devices M2 and M4, and an n-channel switch M3, for resetting, and a source-coupled pair M5 and M6. The operation of the 14 regenerative comparator is divided into the reset phase and the regeneration phase. In both clock phases, the transistor pair M2-M4 causes a negative resistance from VD1 to ground and VD2 to ground. Equivalently, this can be expressed as a negative resistance between nodes “VD1” and “VD2” [3]. In reset phase, the CLK signal is held high which connects the nodes VD1 and VD2 through a low-resistance path (M3) and results in a net positive resistance between the nodes VD1 and VD2. In the regeneration phase, the CLK signal is held low which leaves only a negative resistance between nodes VD1 and VD2. As a result, any difference in voltage between the nodes VD1 and VD2 at the start of regeneration will be exponentially amplified causing one of these nodes to go high and other to go low. I M5 M6 Vinn Vinp CLK M3 VD1 VD2 M2 M4 Figure 3.1 Schematic of a typical regenerative comparator. The input applied to a source-coupled pair M5-M6 controls the balance of signal currents going to the cross-coupled pair. The MOS devices M4 and M2 can be represented using 15 two voltage-controlled current sources as in Figure 3.2. The parasitic capacitance at each node VD1 and VD2 is shown as (CP). The MOS device M3 is used to reset the comparator using the CLK signal. When the CLK signal is high, the MOS device M3 acts as a resistor between the nodes VD1 and VD2 with a resistance of 2RRST. In the difference-mode half circuit, this will result in a resistance of RRST from node VD1 to ground and from node VD2 to ground. The reset resistance is very high during the regeneration phase and relatively low during the reset phase. Due to the positive feedback from the cross-coupled pair M2-M4, a negative resistance RRGN seen from node VD1 to ground and from node VD2 to ground (some authors [3] define this resistance from node VD1 to node VD2). Hence during the reset phase the resistance to ground from each side is (RRST|| RRGN) and during the regeneration phase the resistance is simply RRGN. The mathematical analysis of the comparator model will be done, in section 3.3, using a difference-mode half-circuit as the cross-coupled pair circuit is symmetric. VD 2 VD1 RRST CP g m 2VD 2 g m 4VD1 CP RRST Figure 3.2 Two cross-coupled current sources represent the cross-coupled latch pair. 16 3.3 MathematicalModel In order to validate the Verilog-AMS regenerative comparator model the dynamic response of the model needs to be compared with that of an analytical model. The dynamic response of an analytical model is pretty much its response to time-varying inputs. The results of the comparison depend on the analog inputs a little before and a little after the clock edge that starts the comparison. The analytical model of the practical comparator can be modeled using an idealized comparator, with ideal sampling accuracy, preceded by a time-window function [3]. Figure 3.3 shows the block diagram of the model used for a practical comparator. The time window function has an impulse response of 𝑤(𝑡). The input of the idealized comparator is sampled at t = 0 and the slicer amplifies the sampled value to a full scale output. As the model uses an idealized comparator and slicer, the model lacks the time delays for the outputs to regenerate to full-scale values, compared to practical comparators. The function 𝑤(𝑡) is due to the time constants at the nodes VD1 and VD2, in Figure 3.1, during the reset and the regeneration modes. The function 𝑤(𝑡) expresses the sensitivity of the comparator to pre- and postclock inputs, an analytical result for 𝑤(𝑡) will now be presented [3]. The response of the comparator to time-varying inputs can be analyzed using the smallsignal difference mode half circuit in Figure 3.4. The input current is represented by 𝑖𝑖𝑛 . The value of capacitance, parasitic capacitance of the MOS device, is Cp and resistance 17 will be R1 in reset mode and R2 in regeneration mode. The resistance has a positive value during the reset mode, and switches to a negative values during the regeneration mode. Figure 3.3 Model used for practical comparator [3]. Figure 3.4 Difference-mode half-circuit (τ = 𝑅𝐶𝑝 ). These values are given by: 𝑅1 = (𝑅𝑅𝑆𝑇 | |𝑅𝑅𝐺𝑁 ) and 𝑅2 = 𝑅𝑅𝐺𝑁 (4) The time constants during the reset mode will be called τ1 and the time constant during the regeneration mode will be called τ2. Accordingly, τ1 has a positive value and τ2 has a negative value. Assume the comparator as a linear and time-invariant system, to be in reset mode for 𝑡 <0, and in regeneration mode for 𝑡 >0 and the circuit switches instantaneously from reset to regeneration mode at time 𝑡=0 [3]. The following analysis will consider the system as two time-invariant systems, first one while 𝑡<0 and second 18 one for 𝑡 >0. The capacitor voltage, 𝑣𝑜 is the only state of the system, will be kept constant across the discontinuity at 𝑡=0. The total response will be found by adding the zero-state response and the zero-input response. In the reset mode, 𝑡 <0, the comparator is a linear time-invariant system and the voltage 𝑣𝑜 , voltage across the capacitor Cp, can therefore be represented as: 𝑣𝑜 (𝑡) = 𝑖𝑖𝑛 (𝑡) ∗ ℎ (𝑡) (5) Where ∗ denotes convolution, 𝑖𝑖𝑛 (𝑡) is the input signal and ℎ(𝑡) the impulse response. If ℎ1 (𝑡) is the impulse response of the circuit in reset mode and ℎ2 (𝑡) the impulse response in the regeneration mode, then these can be represented as follows, where 𝑢(𝑡) is the unit step function: 𝑅 t ℎ1 (𝑡) = ( 𝜏 1) exp( − τ ) 𝑢(t) 1 𝑅 1 t ℎ2 (𝑡) = ( 𝜏 2 ) exp( − τ ) 𝑢(t) 2 2 (6) (7) To find the zero-input response, 𝑣1 (𝑡), evaluate 𝑣𝑜 at t=0 using (5) and then multiply it by t the natural response of regeneration mode, where exp( − τ ) is the natural response. 2 𝑣𝑜 (0) = 𝑅1 𝜏1 0 𝜆 ∫−∞ 𝑖𝑖𝑛 (𝜆) exp (𝜏 ) 𝑑𝜆 1 (8) 19 𝑡 𝑅 0 𝜆 𝑣1 (𝑡) = exp(− 𝜏 ) 𝜏 1 ∫−∞ 𝑖𝑖𝑛 (𝜆) exp (𝜏 ) 𝑑𝜆 2 1 (9) 1 Where λ is the time index of convolution. Similarly, the zero-state response of the circuit for the regeneration mode can be found by convolution of input current with the corresponding impulse response of the circuit. Finally the zero-input and zero-state responses are added together and simplified. The resulting expression is given by [3]: 𝑡 𝑣𝑜 (𝑡) = exp (− 𝜏 ) 2 0 𝜆 ∫ 𝑖 (𝜆) exp (𝜏 ) 𝑑𝜆 𝜏1 −∞ 𝑖𝑛 1 𝑅1 𝑅2 + 𝜏2 ∞ 𝜆−𝑡 ∫0 𝑖𝑖𝑛 (𝜆) exp ( 𝜏 ) 𝑑𝜆 2 (10) 𝑡 The expression in (10) can be simplified by factoring exp ( − 𝜏 ) out of the integral 2 resulting in: 𝑡 𝑉𝑜 (𝑡) = [ exp (− 𝜏 )] [𝑖𝑖𝑛 (𝑡) ∗ 𝑤(𝑡)] (11) 2 𝑡 The factor exp (− 𝜏 ) is the natural response of the comparator in the regenerative mode 2 and the impulse response 𝑤(𝑡) is given by: 𝑅 𝑡 𝑅 𝑡 𝑤(𝑡) = ( 𝜏 1 ) exp (− 𝜏 ) 𝑢(𝑡) + ( 𝜏 2) exp (− 𝜏 ) 𝑢(−𝑡) 1 1 2 2 (12) It should be noted that the negative time constant 𝜏2 implies that the corresponding comparators output will move towards saturation exponentially. This behavior of exponential saturation when building a practical model is discussed in Chapter 4. 20 The important consequence of (11) is that the practical comparator considered here can be modeled as an idealized comparator proceeded by convolution with 𝑤(𝑡). It should be noted that 𝑤(𝑡) is similar to impulse response, but is non-causal. This is because the input signals after 𝑡=0 have an effect on the eventual output. The ideal comparator acts on only the instantaneous input value at 𝑡 = 0. However for a practical comparator, the comparison depends on values before 𝑡 = 0 and after 𝑡 = 0. For such a comparator Figure 3.5 shows the graph of the function 𝑤(𝑡) and the corresponding regions for the regeneration and reset. The weighted values for 𝑡 > 0 are present on the left side and 𝑡 < 0 are present on the right side in the Figure 3.5. The Figure 3.5 can be visualized as reverse of time windowing function used to determine the effective input at 𝑡 = 0. w(t ) t exp 2 t exp 1 t 0 time Regeneration Reset Time-windowing function is w(t ) Figure 3.5 Comparator Impulse response and windowing function [3]. 21 To compare the simulation results of Verilog-AMS comparator models output to that of the mathematical model, we need to examine 𝑤(𝑡) in frequency domain. Taking the Fourier transform of 𝑤(𝑡) leads to: 𝑊(ϳ𝜔) = 1 Cp (1+ ϳω(τ τ1 −τ2 ) 2 1 + τ2 )−ω τ1 τ2 (13) Looking at (11), it can be understood that a smaller 𝜏2 will create a full-scale output sooner. Hence the value of regeneration constant is almost always as minimized as presented in [3]. 𝑊(ϳ𝜔) = g m2 (1+ ϳω(τ R1 −R2 ) 2 1 + τ2 )−ω τ1 τ2 (14) If we simply add the transconductance, gm2, of the input source-coupled pair M5 and M6 then (13) can be written as in (14). This implies that the DC gain at reset is gm2 (R1- R2). Also the implication is that the different gains in the reset mode may have an effect on performance, so minimizing 𝜏2 and varying 𝜏1 will create different 𝑊(ϳ𝜔). The implications and results of 𝑊(ϳ𝜔) are further discussed in [3], which will be used here to compare the results obtained from simulation of the Verilog-AMS comparator model in Chapter 5. 22 Chapter 4 REGENERATIVE COMPARATOR VERILOG-AMS MODEL 4.1 Macro Model The Regenerative comparator analyzed in the Chapter 3 is modeled using the VerilogAMS macro-model approach that will be presented in this chapter. This approach requires the regenerative comparator to be modeled using primitive elements. The start point to model the comparator is the difference-mode half circuit shown in Figure 3.4. The model needs to switch from regenerative mode to reset mode at negative and positive edges of a clock respectively. To accommodate this behavior in the model, for a continuous operation, a switch can be used controlled by a clock input. Figure 4.1 shows the schematic of the regenerative comparator model that will be built using VerilogAMS. The operation of this model will be analogous to the difference-mode half circuit. When the switch, SW1, is closed the total resistance will be 𝑅1 = (𝑅𝑅𝑆𝑇 | |𝑅𝑅𝐺𝑁 ) and when open 𝑅2 = 𝑅𝑅𝐺𝑁 . The clock edge controls the switch, SW1, in the macro model circuit. The differential input voltage that is converted to single-ended current represented by iin, is loaded by resistance (RRST || RRGN) when the switch is closed. The resistance (RRST || RRGN) will be coded in Verilog-AMS model as positive resistance, similar to the actual circuit behavior, 23 as explained in section 3.2. When the switch is open the resistance is just RRGN, which is negative. The time constants for the model in Figure 4.1 are as follows: a) when the switch is closed: 𝜏1 = ((𝑅𝑅𝐺𝑁 || R RST )CP ) (15) b) when the switch is open: 𝜏2 = 𝑅𝑅𝐺𝑁 𝐶𝑃 (16) SW1 iin RRST RRGN Cp Figure 4.1 Initial Macro model of a regenerative comparator. The regenerative comparator model user can set these time constant parameters along with the parasitic capacitance to control the reset and regeneration resistances of the model or vice-versa. In the above model when a small positive input current iin is applied, with the switch open, the output voltage across the capacitor increases exponentially with a time constant of 𝐶𝑃 (𝑅𝑅𝐺𝑁 ). The problem being the absence of no limiting circuit for this exponential 24 rise in the voltage value causes the simulator to crash with a very huge negative voltage value. Similarly when a small negative input current -iin is applied, the simulator crashes with a huge positive value. 4.2 Voltage Limiting Diodes The problem with the simulator crash can be solved by adding voltage limiting diodes on either sides of the circuit. The diodes need to be ideal diodes; hence any capacitive effective of the normal diodes must be removed from the diode models. When the voltage at the input of the diode, Vout, is higher than VDD by Von the model limits the output to VDD. When the voltage at the input of the diode is less than VDD a very huge OFF resistance is used to create smoother outputs. The new circuit with the diodes is shown in the Figure 4.2. VDD Vout SW1 iin RRST RRGN Cp VSS Figure 4.2 Regenerative comparator model with limiting diodes. 25 4.3 Voltage Controlled Current Source The input of the regenerative comparator model is desired to have a differential voltage input. The model converts this voltage to current by using a voltage controlled current source (VCCS), for two main reasons: 1) This models the inputs source-coupled pair of the actual comparator, and 2) the ideal VCCS is unilateral, so the voltage resulting from the regeneration does not kick back into the inputs of the comparator model. The voltage controlled current source (VCCS) block takes differential voltage as input and current as the output. The VCCS block typically has a gain value (gm) to control the output current with respect to input voltage. The reset gain is 𝑔𝑚 (𝑅𝑅𝑆𝑇 || 𝑅𝑅𝐺𝑁 ). The reset gain should not be so high that the comparator will activate the swing-limiting diodes in the reset mode for normal inputs. Voltage gain of 1 or 2 is typical. Figure 4.3 shows the modified model schematic. The 𝑔𝑚 cell provides a single ended current of 𝑣𝑖𝑛 𝑔𝑚 to the half-circuit having RRST, RRGN and CP. Where as in a physical comparator, all the circuitry is differential and the source-coupled pair supplies currents of 𝑣𝑖𝑛 𝑔𝑚 /2 and – 𝑣𝑖𝑛 𝑔𝑚 /2 to a differential regenerative transistor pair. Therefore the 𝑔𝑚 in Figure 4.3 has to be set to half of the 𝑔𝑚 of the input transistors of the actual comparator. The input of the comparator is explicitly differential in order to offer the user the same input connectivity as the physical comparator. A step response of the regenerative comparator model is shown in Figure 4.4, by stepping positive node voltage from 0v to 100mv, setting negative node voltage at 0v, time 26 constants at 1ns and –1ns and at clock frequency of 100 MHz. The output response of the comparator model shown in Figure 4.4 points out that at the positive edge of the clock, when the switch SW1 is open, the output starts increasing to 5.5v and at negative edge of the clock, when the switch SW1 is closed, and the output starts resetting back to 0v. This response continues with the changing clock until there is a change in the input. It should be noted that the output is measured with respect to VSS. VDD Vout SW1 gm RRST RRGN Cp VSS Figure 4.3 Regenerative comparator with differential voltage inputs. 4.4 Input Signal Limiting The input of the regenerative comparator can have huge input values swinging between VDD and VSS. These huge input values can cause large amounts of current to flow into the circuit. A real comparator needs a few millvolts difference at input to make a decision and also has a source-coupled pair as the input stage which predominantly has a limitation for the maximum sinkable current. So to limit the amount of voltage and current that can flow into the RC circuit, an additional current swing minimizing circuit 27 and limiting circuit needs be added. To limit the current, the VCCS in Figure 4.3 is replaced with the circuit of Figure 4.5 to make a current-limited. The VCCS gain is now gm1 R1 gm2, and the output current limit is V1 gm2. The parameter V1 value can be set by the user. Figure 4.4 Step response of the model at various clock edges 28 V1 iOUT vID gm2 g m1 R1 V1 Figure 4.5 Updated Voltage Controlled Current Source (VCCS) schematic, by adding additional diodes and additional pull down resistance. This entire cell replaces the single gm-cell in the Figure 4.3. 4.5 Tweaking the Model The regenerative comparator model developed using Verilog-AMS is provided with parameters to tweak the operation of the model. The various parameters included for the end user to tweak the model are: 1)Reset Tau (τ1) 2)Regeneration Tau (τ2) 3)Parasitic Capacitance (CP) 4)Reset gain of the VCCS model 5)Cut-off voltage (V1) for the input signal limiting diode 6)Operating Voltage for the model, i.e. VDD and VSS. The reset and regeneration time constants given calculate the ratio of the resistors. The capacitance determines the resistance values using the time constants. Once the resistor values are known, and a reset gain is given, the value of the 𝑔𝑚 is determined. The Verilog-AMS code for the model can be found in APPENDIX A for further details. 29 Chapter 5 SIMULATION RESULTS 5.1 Introduction The regenerative comparator model was developed using Verilog-AMS as explained in the chapter 4. This chapter deals with simulation of the model with simple inputs, design of Dynamic Offset Test Bench (DOTB) [12] and finally testing the model using the Dynamic Offset Test Bench. The model is simulated using Mentor Graphics® ADMS tool. The outputs of the simulation are analyzed using the EZ-wave® waveform viewer tool. The design of the DOTB is done using Verilog-AMS to increase the simulation speed. 5.2 Simulation of the Comparator Model The regenerative comparator basically compares the inputs provided and gives the corresponding output based on the input. If the input of the comparator is 𝑣𝑃 − 𝑣𝑁 > 0, then the output is pulled high. If the input of the comparator is 𝑣𝑃 − 𝑣𝑁 < 0 then the output is pulled low. The positive edge of the clock, to the comparator, starts the comparison and negative edge of the clock reset the comparator to be used for the next comparison. The simulation of the comparator is done by setting VDD to 5v and VSS to -5v. This causes the output of the comparator model to swing to either VDD or VSS values. To make the simulation inputs easier, one of the inputs of the comparator is fixed 30 to GND, i.e. 0v, and the second input is connected to a piecewise waveform generator. The circuit schematic is shown in Figure 5.1. VDD Waveform Generator SW1 VCCS RRST dataout RRGN Cp datain1 VSS Figure 5.1 Circuit schematic used for simulation Figure 5.2 shows the output response of the comparator model for various inputs. In the Figure 5.2, when the input is below 0v, the comparator pulls the dataout node to (VDD + Vdiode_cutoff) on the positive edge of the clock. When the input of the comparator is above 0v the comparator pulls the dataout node to (VSS – Vdiode_cutoff) on the positive edge of the clock. It should be noted that the comparator resets its output on the negative edge of the clock. The clock rate defined for this simulation is 100MHz and Vdiode_cutoff was set to 0.6v. At lower clock rates, i.e. 10MHz, the comparator output is held to the same values until the model detects a negative clock edge as shown in Figure 5.3. A RS latch is attached to the output stage to above model hold the outputs to either high or low, so that it appears as digital value for either 100 MHz or 10MHz comparator outputs. 31 Figure 5.2 Simulation of the comparator model with clock rate of 100MHz. 32 Figure 5.3 Simulation of the comparator model with clock rate of 10MHz. 33 5.3 Dynamic Offset Test Bench Comparators used in high speed ADC’s have a decision threshold ideally at zero. This decision threshold can shift due to component mismatches and other non-ideal conditions. The amount by which the threshold shifts is called the input offset voltage. Simulations to determine the input offset voltage of the comparator are difficult, as the designer must try different inputs in order to find the actual input offset voltage and can be a time consuming process. A simulation technique presented by [12], dynamic offset test-bench (DOTB), will be utilized to understand the DC offset and other parasitic mismatches caused by varying the reset and regeneration tau for the comparator model. The results from the DOTB can also be used to understand the effective sampling time accuracy of the comparator for various time constants for the model. The technique presented by [12] uses idealized components to test the comparator. The components for the DOTB are created using Verilog-AMS for faster simulation. Figure 5.4 shows the schematic of the DOTB created to test the comparator. The dynamic offset test-bench consists of a latch circuit, an integrator, a sinusoidal wave generator and the comparator under test. The output of the comparator model designed using Verilog-AMS swings from VDD to VSS, i.e. 5v to -5v. These outputs have to be readjusted to be used by the SR latch to be applicable for the DOTB. The voltage adjustor model shifts the output of the comparator to limit between 0 to 5v. The voltage adjuster model combined with SR latch model works similar to a normal SR latch combined to real comparator. Second waveform in the Figure 5.5 shows the output of the integrator. The output of the 34 integrator Vout_integrator peak value depends on the integrator gain. A smaller peak-to-peak variation in Vout_integrator leads to greater accuracy, but will also increase the simulation time. For the DOTB simulations described below, the integrator output was about 50mV peak-to-peak. Comparator VDD CLK LATCH dataout SW1 VCCS RRST Waveform Generator RRGN datain S Q R Qb Voltage Adjustor Cp VSS Integrator Vout_integrator Unity Gain Differential Buffer Figure 5.4 Dynamic offset test-bench block diagram. 5.4 Servo Loop Test Using DOTB The regenerative comparator model is tested using the servo loop test using dynamic offset test-bench as described in [3] and [12]. A sinusoidal signal generator is used as one of the inputs to the comparator and the other input is connected to the output of the 35 integrator. The input sine wave signal is phase shifted by an amount 𝜑 = 6° relative to input clock, as shown in Figure 5.6. The servo loop is allowed to settle, then the process is repeated for an increased phase shift between the sine wave and the clock, for total of 60 values of φ. The servo loop is run for 60 incremental values of φ, i.e. 360° of sine wave, for various frequencies between 1 MHz to 100 MHz to study the effective input magnitude and phase as frequency increases. 36 Average of peak-to-peak values Figure 5.5 Outputs of various blocks in the servo loop test. 37 Figure 5.6 Phase difference between inputs for servo loop test. 5.5 Simulating the design The output of these 60 simulations is used to understand the frequency response of the comparator and the effective sampling time-window of the comparator. It should be observed that the ideal comparator samples the sine wave on the positive edge of the clock for each of the 60 simulations. To understand the sampling accuracy of the comparator we took the peak-to-peak average of the integrator output once the loop settles, as shown in Figure 5.5. These average values from the servo loop test, for all of the 60 runs, if reconstructed, form a single sine waveform as shown in Figure 5.7. The reconstructed sine waveform represents the effective input of the comparator, and makes evident the magnitude and phase shift corresponding to W(jω). For different comparator time constants, there is a different W(jω). 38 Figure 5.7 Servo loop test simulation reconstructed output after 60 runs. X axis is clock to input phase and Y axis is effective input voltage. 5.6 Automating the Simulation Environment A major hurdle in the servo loop test is to get the average values of the integrator output over several complete cycles after the loop has reached steady-state. The starting peak time of the integrator output varies for different values of regeneration tau, reset tau and clock frequencies. Also the peak value changes for every run for any given set of regeneration tau and rest tau values. The best possible way to get the average value for the run is by observing the SR latch outputs. Figure 5.5 waveforms show that the integrator shifts it direction based on the SR latch output change. It can be observed that SR latch output does not change after the first two positive edges. Starting with the third positive edge of the SR latch output to a total of 17 edges, both positive and negative SR latch output swing combined gives a total of 8 peak-to-peak values of the integrator, 39 which will provide the average value needed from the integrator output. This average value represents the input sampled value of the sine wave by the comparator. These values have to be obtained for each of the 60 runs to reconstruct the sine wave shown in Figure 5.7. The simulation results obtained by varying the time constants for different frequencies can be seen in Figures 5.8, 5.9, 5.10, 5.11, 5.12, 5.13. The following automation code is used to measure the average values for various time constant corners: .meas tran vcomp_start TRIG AT=0 TARG V(Q_out) val=2.5v cross=2 .meas tran vcomp_stop TRIG AT=0 TARG V(Q_out) val=2.5v cross=17 .meas tran vint_avg AVG v(Vout_intgrtr) FROM=vcomp_start TO=vcomp_stop 5.7 Interpreting Simulation Results The analysis done in chapter 3 can be used to interpret the simulation results obtained from the DOTB for various clock frequencies. The reset tau has been kept at a constant 1.0ns for all the simulations. It can be observed that as value of regeneration tau drifts away from the reset tau, there is a certain amount of phase shift seen in the sine wave. Also a smaller regeneration tau increases the magnitude of the effective comparator input at higher frequencies as seen from Equation (12). It can be observed that if the phase shift is not well-controlled, the effective sampling time of the comparator for certain fast changing sinusoids may be uncertain. Clearly, as stated by [3] and results from the DOTB simulations suggest that for minimal phase shift, i.e. for a comparator to have sampling accuracy at the zero crossing of the input, it’s desirable to set τ2 = - τ1. 40 Figure 5.8 Effective inputs at 1 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. 41 Figure 5.9 Effective inputs at 10 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. 42 Figure 5.10 Effective inputs at 25 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. 43 Figure 5.11 Effective inputs at 50 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. 44 Figure 5.12 Effective inputs at 80 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. 45 Figure 5.13 Effective inputs at 100 MHz for reset tau value of 1ns and regeneration tau values of 0.3, 0.8, 1.0 and 1.2ns respectively. 46 Figure 5.14 Effective inputs at different frequencies obtained from the servo loop test. The phase shift at value 0 in Figure 5.14 has been observed to change to be from -131mV to 49.5mv. This indicates the phase shift across the various frequencies using different time constants. The amplitude can be seen to change from 494mv to 404mv, with input signal amplitude of 500mv. The magnitude and phase plots of the behavioral model for various frequencies and various τ1 (reset) values, keeping τ2 (regeneration) constant to a value of -1ns, as shown in Figure 5.15 and Figure 5.16. These values appear to be 47 consistent with results obtained by [3] as shown in Figure 5.17. The results from the graphs suggest that if the excessive phase shift is not well controlled, the effective sampling time of the comparator for sinusoids may be uncertain. Clearly, for minimal phase shift the option of τ1 = - τ2 is desirable. The plots in the Figure 5.15 and Figure 5.16 were obtained by simulating the comparator model at only a handful of frequencies. This resulted in the sharp kinks seen in both the curves. The plot in Figure 5.17 was generated using MATLAB code by [3] resulting in continuous waveforms. The plots in Figure 5.15 and Figure 5.16 shows the magnitude and phase plots of W(jω) as a function of frequency. It was been seen in Figure 5.15 that a smaller τ1 increases the magnitude of the effective comparator input at high frequencies. Also it can be noted from Figure 5.16 that a smaller τ1 increases the phase shift of the effective comparator input at high frequencies. 48 Figure 5.15 Magnitude plot using windowing function for the behavioral model. 49 Figure 5.16 Phase plot using windowing function for the behavioral model. 50 00 -5 1 0.3ns 10-10 W ( j ) -15 (dB) 20-20 0.7ns 1.0ns . ns 1.2ns 2 10 -25 30-30 -35 6 10 6 10 4040 W ( j ) 7 10 7 8 10 8 10 10 Frequency, Hz. 9 10 9 10 1 0.3ns 3030 0.7ns 1.0ns Phase, 2020 1.2ns Deg . 1010 . ns 2 10 00 -10 -10 6 10 10 6 7 10 7 8 10 8 10 10 Frequency, Hz. 9 10 10 9 Figure 5.17 Magnitude and Phase plots using windowing function for the mathematical model. 51 Chapter 6 CONCLUSIONS 6.1 Accomplishments This project report has detailed the development of a behavioral model for a regenerative comparator using Verilog-AMS. The model has been parameterized to control the values of time constants, τ1 and τ2, parasitic capacitance Cp and operational voltage of the model VDD. The model has been parameterized such that it can be embedded into other designs with minor modification to the parameter values. The developed model has been verified for its functionality at different frequencies and with different combinations of time constants. The testing of the model was done utilizing the time-windowing function of the comparator. The results obtained from the analysis of the comparator showed that the desirable minimal phase shift is obtained for the option τ1 = -τ2. Hence a well-controlled reset transistor in the actual design is optimal. The project also outlined the development of Dynamic Offset Test Bench (DOTB) for testing the comparator using Verilog-AMS with minor enhancements. The results obtained from the DOTB matched that of the mathematical analysis results. The project report also detailed various problems faced in the development of the model and how to overcome such scenarios. 52 A Shell script was also developed as part of the test-bench to automate the data collection process during the simulation. This script proved as an essential part of the simulation as it helped to decrease the amount of time required to process the output data. The complete code has been automated and parameterized to make the behavioral model reusable across various designs. 6.2 Future Work Although a behavioral model has been developed in Verilog-AMS and has been tested using Verilog-AMS test-bench, its capabilities were not tested in a mixed circuit simulation with other SPICE circuit simulations. Also further investigations into other non-linear aspects of the model can be done and incorporated to get some complex behavior of the model, like full reset functionality, spline functions based curve fitting and adding noise models. 53 APPENDIX A Source Code for Behavioral Model and Test Bench // Library.va // Various simple components used to build test-bench and DUT. // Created by Pranav Cherupalli `ifndef __DEFINES__ `define __DEFINES__ `include "disciplines.vams" `include "constants.vams" `endif `timescale 1ns/1ps //Capacitor Block module cap1(p, n); inout p, n; electrical p, n; parameter real c=1 from [0:inf); analog begin I(p,n) <+ c*ddt(V(p,n)); end endmodule //Simple Resistor Block module resistor(p, n); inout p, n; electrical p,n; parameter real res=1 from [0:inf); analog begin V(p,n) <+ res*I(p,n); end endmodule 54 //Clock generator Block module clk_gen(clk); output clk; reg clk; parameter real clk_period = 400; initial begin clk = 0; forever clk =#(clk_period/2) ~clk; end endmodule //Ideal Diode Block, changed the parameters to suite the design module DIODEideal(p,n); inout p,n; electrical p,n; parameter real Vg = 0.6; parameter real rD = 1.0 from (1.0e-6:inf]; parameter real rDOFF = 1.0e8 from (1.0e-6:inf]; // Cut-in voltage of diode // ON resistance of diode // OFF resistance of diode analog begin if (V(p,n) < Vg) I(p,n) <+ V(p,n)/rDOFF; else I(p,n) <+ (V(p,n) - Vg)/rD + Vg/rDOFF; end endmodule //Integrator Block designed out of the transfer function equation module my_integrator( vout, vip, vin); input vip, vin; output vout; electrical vout, vin, vip; electrical input_vol; parameter real RC_Val = 0.0001 exclude 0; 55 parameter real DC_Val = 0; real Inv_RC_Val; analog begin @(initial_step) Inv_RC_Val = -1/RC_Val; V(input_vol) <+ (V(vip) - V(vin)); V(vout) <+ Inv_RC_Val * idt(V(input_vol), DC_Val); $bound_step(0.00001); end endmodule //RS Latch Block to be used after the comparator. module my_rs_latch ( Q, Qb, datain); input datain; output Q, Qb; electrical datain; electrical Q, Qb, Set, Reset; parameter real Vth_pos = 4.6 from (-5:5); parameter real Vth_neg = -4.6 from (-5:5); parameter real VDD = 5 from (-10:10); parameter real AGND = 0 from (-10:10); parameter real SR = 1.0e12 from (0:inf); real set; real reset; real q; real qb; real VQ; real VQb; analog begin @(cross(V(datain) - Vth_pos, +1)) begin set = 1; reset = 0; end 56 @(cross(V(datain) - Vth_neg, -1)) begin set = 0; reset = 1; end if(V(datain) > 4.9) begin set = 1; reset = 0; end if(V(datain) < -4.9) begin reset = 1; set = 0; end q = V(Q); qb = V(Qb); V(Set) <+ set; V(Reset) <+ reset; if(set) begin VQ = VDD; VQb = AGND; end else if (reset) begin VQb = VDD; VQ = AGND; end else begin VQ = q; VQb = qb; end V(Q) <+ slew (VQ, SR, -1*SR); V(Qb) <+ slew (VQb, SR, -1*SR); $bound_step(0.001/100); end endmodule 57 //Block to Sample the input signal on the posedge of clock module my_sampler (clk, inpwave, outsignal); input clk, inpwave; output outsignal; electrical inpwave, outsignal; real outVal; wire clk; analog begin @(initial_step) begin outVal = 0; end @(posedge clk) begin outVal = V(inpwave); //$display("Outval is %f", outVal); end V(outsignal) <+ outVal; end endmodule //SineWave generator Block module my_sine(outp); output outp; electrical outp,gnd; ground gnd; parameter real freq = 10e3 exclude 0; parameter real phase = 0; parameter real amplitude = 1.0 exclude 0; analog begin V(outp,gnd) <+ amplitude*sin((`M_TWO_PI*freq*$abstime) + phase); end endmodule 58 //PWL block in Verilog_AMS for different time steps and voltages module my_vsrc (outp); output outp; electrical outp; //Initially the parameters are fixed to 0v, so that there is no Signal parameter real t0 = 0n from [0:inf); parameter real Vt0 = 0.000 from (-5.1:5.1); parameter real t1 = 1n from [0:inf); parameter real Vt1 = Vt0 from (-5.1:5.1); parameter real t2 = 2n from [0:inf); parameter real Vt2 = Vt1 from (-5.1:5.1); parameter real t3 = 3n from [0:inf); parameter real Vt3 = Vt2 from (-5.1:5.1); parameter real t4 = 4n from [0:inf); parameter real Vt4 = Vt3 from (-5.1:5.1); parameter real t5 = 5n from [0:inf); parameter real Vt5 = Vt4 from (-5.1:5.1); parameter real t6 = 6n from [0:inf); parameter real Vt6 = Vt5 from (-5.1:5.1); parameter real t7 = 7n from [0:inf); parameter real Vt7 = Vt6 from (-5.1:5.1); real outp_volt; analog begin @(timer(t0)) outp_volt = Vt0; @(timer(t1)) outp_volt = Vt1; @(timer(t2)) outp_volt = Vt2; @(timer(t3)) outp_volt = Vt3; @(timer(t4)) outp_volt = Vt4; @(timer(t5)) outp_volt = Vt5; @(timer(t6)) outp_volt = Vt6; @(timer(t7)) outp_volt = Vt7; V(outp) <+ transition(outp_volt,0,0,0); end endmodule 59 //This block generates difference signal on the output module signal(diffinp, diffinn, outp); inout diffinp, diffinn; output outp; electrical diffinp, diffinn; electrical outp; real val_diffp; real val_diffn; analog begin val_diffp = V(diffinp); val_diffn = V(diffinn); V(outp) <+ transition((val_diffp - val_diffn),0,0,0); end endmodule //Ideal Switch block, taken from Ken Kundurts book module my_switch (p,n, pcntrl, ncntrl); input pcntrl, ncntrl; output p, n; electrical p, n, pcntrl, ncntrl; parameter real thresh = 0; analog begin @(cross(V(pcntrl, ncntrl) - thresh, 0)) ; if(V(pcntrl, ncntrl) > thresh) V(p,n) <+ 0; else I(p,n) <+ 0; end endmodule 60 //Ideal Voltage Controlled Current Source module vccs (p,n,ps,ns); parameter real reset_gain = 1; output p,n; input ps,ns; electrical p,n,ps,ns; analog I(p,n) <+ reset_gain*V(ps,ns); endmodule //Ideal Voltage Controlled Voltage Source module vcvs (p, n, ps, ns); input ps, ns; output p, n; electrical p, n, ps, ns; parameter real gain = 1; analog V(p,n) <+ gain*V(ps,ns); endmodule 61 // Regenerative Comparator Block (RCbloc.va) // Uses library.va components //Created by Pranav Cherupalli `include "disciplines.vams" `include "constants.vams" module rcblock ( datain, clk, dataout, gnd); input clk; input datain; output dataout; electrical datain, dataout, gnd; electrical datain1; ground gnd; wire clk; electrical VDD_volt; //For Diode electrical VSS_volt; //For Diode electrical midpoint; parameter real reset_tau = 1e-8 from (-inf:inf); parameter real regen_tau = -1e-8 from (-inf:inf); parameter real reset_gain1 = 0.0001 from (0:inf); parameter real reset_gain2 = 0.0001 from (0:inf); parameter real resistor1 = 1000 exclude 0; parameter real cap = 0.1n from (-inf:inf); parameter real VDD = 5 from (-50:50); parameter real VSS = -5 from (-50:50); parameter real gain2 = (reset_gain2 * cap) / (reset_tau * reset_gain1); parameter real gain1 = 1; //* resistor1/10; //Internal real params real negRes; real posRes; real changeResis; real mid_val; real VL; //Voltage controlled current source 1 //vccs #(.reset_gain(gain1)) CS1(.n(datain1), .p(gnd), .ps(datain), .ns(gnd)); //Resistor to ground for the first gm stage. 62 resistor #(.res(resistor1)) R1(.p(datain1), .n(datain)); //clamper to limit the dataout1 value DIODEideal #(.Vg(0.1)) DA1(datain1, gnd); DIODEideal #(.Vg(0.1)) DA2(gnd, datain1); //Clamper Diodes DIODEideal #(.Vg(0.0)) D1(dataout, VDD_volt); DIODEideal #(.Vg(0.0)) D3(VSS_volt, dataout); //Voltage Controller Current Source 2 vccs #(.reset_gain(gain2)) CS2(.p(dataout), .n(gnd), .ps(datain1), .ns(gnd)); //Simple Capacitor cap1 #(.c(cap)) C1(.p(dataout),.n(gnd)); analog begin @(initial_step) begin negRes = regen_tau/cap; posRes = ((negRes*reset_tau)/((negRes*cap)-reset_tau)); $display("Values of Reset_tau=%14.12f, Regen_tau=%14.12f, Reset_gain=%f",reset_tau, regen_tau, reset_gain2); $display("Value of PosRes=%f, negRes=%f", posRes, negRes); changeResis = posRes; end //additional code to hold the Diode value to constant. V(VDD_volt) <+ (VDD); V(VSS_volt) <+ (VSS); @(posedge clk) begin changeResis = negRes; end @(negedge clk) begin changeResis = 1/((1/posRes)+(1/negRes)); end V(dataout, gnd) <+ (changeResis) * I(dataout, gnd); end endmodule 63 // Testbench for the comparator (tb_comp.va) // Created by Pranav Cherupalli `ifndef __DEFINES__ `define __DEFINES__ `include "discipline.vams" `include "constants.h" `endif `include "library.va" `include "rcblock.va" `timescale 1ns/1ps module tb_comp; electrical step_in; electrical dataout; electrical gnd; electrical posnode, negnode; electrical Q_out, Qb_out; electrical Vout_intgrtr; electrical wave; electrical VIN; ground gnd; wire clk; //frequency relative to clkCycle parameter real sineWaveAmp = $param("sinewaveampl"); parameter real sineWaveFreq = $param("sinewavefreq"); parameter real sineWavePhase = $param("sinewavephase"); //360°= 2*pi, 6°= 0.1466 parameter real clkCycle = $param("clockcycle"); parameter real posThresh = $param("posThresh"); parameter real negThresh = $param("negThresh"); parameter real RCVal = $param("Intgrtr_RCval"); parameter real initialDCVal = 0; //parameters of RC block parameter real reset_tau = $param("reset_tau"); parameter real regen_tau = $param("regen_tau"); parameter real reset_gain1 = $param("reset_gain1"); parameter real reset_gain2 = $param("reset_gain2"); parameter real cap = $param("capacitance"); 64 parameter real VDD = 5 from (-50:50); parameter real VSS = -5 from (-50:50); //Sinusoidal Input source my_sine #(.freq(sineWaveFreq), .phase(sineWavePhase), .amplitude(sineWaveAmp)) vsine(.outp(wave)); //Signal Difference ckt with clock frequency as parameter signal sig1 (.diffinp(wave), .diffinn(Vout_intgrtr),.outp(step_in)); //Clock Generator Block clk_gen #(.clk_period(clkCycle)) clkgen (.clk(clk)); //Comparator block Implementation rcblock #(.reset_tau(reset_tau), .regen_tau(regen_tau), .reset_gain1(reset_gain1),.reset_gain2 (reset_gain2), .cap(cap), .VDD(VDD), .VSS(VSS)) comp1 (.datain(step_in), .clk(clk), .dataout(dataout), .gnd(gnd)); // Modified RS Latch my_rs_latch #(.Vth_pos(posThresh),.Vth_neg(negThresh)) rs_l1 (.Q(Q_out), .Qb(Qb_out), .datain(dataout)); //Integrator Block my_integrator #(.RC_Val(RCVal),.DC_Val(initialDCVal)) testIntg (.vout (Vout_intgrtr), .vip(Q_out), .vin(Qb_out)); //Dummy Test logic here analog begin V(VIN) <+ 0.1; end endmodule 65 * The Following code is ELDO Simulator Script. * It does not consist of any Verilog-AMS code. *************************************************** * Created by Pranav Cherupalli * Updated Date Feb 21st, 2010, 12:59 AM *************************************************** ********************************** *Setup Conditions for simulator ********************************** .width out=120 ! .option ingold=2 ! .option numdgt=10 ! .option notrclib ! .option noascii ! .option nowarn=100 ! .option probe ! .option captab ! .option tuning=vhigh ! .option itl1=1000 ! .option itl6=1000 ! .option hmin=1e-10 .option trap .option eps=5e-5 .option aex ! Set number of columns in .chi file (text output) Set output format for numbers to Spice 2G6 default Set number of digits for .op and .meas numerical outputs Suppress printing of models/subckts from .lib in .chi file Suppress printing of print/plot outputs in .chi file Suppress printing of warning 100 in .chi file Add only requested outputs to .wdb file (graphical output) Print capacitance table in .chi file Set simulation to high accuracy Set limit for max number of DC iterations (default=100) Transient timestep contol option (see Eldo_ur.pdf) Print measure outputs in .aex file ********************************** * Measurement commands ********************************** .meas tran vcomp_start TRIG AT=0 TARG V(Q_out) val=2.5v cross=2 .meas tran vcomp_stop TRIG AT=0 TARG V(Q_out) val=2.5v cross=17 .meas tran vint_avg AVG v(Vout_intgrtr) FROM=vcomp_start TO=vcomp_stop ********************************* * Simulation specific parameters ********************************* .param sinewaveampl=(0.5) .param sinewavephase=(0.0) .param sinewavefreq=(100000000) ! 100Mhz .param clockcycle=10 ! 10 ns 66 .param posThresh=4.5 .param negThresh=-4.5 .param Intgrtr_RCval=2.7e-5 ********************************* * RC Model specific parameters ********************************* .param reset_tau = 1e-9; .param regen_tau = -1e-9; .param reset_gain1 = 1.0; .param reset_gain2 = 1.0; .param capacitance = 0.1n; .op .tran 0.01n 50.0us ********************************** .alter .param sinewavephase=((0.104720)) .alter .param sinewavephase=((0.209440)) .alter .param sinewavephase=((0.314159)) .alter .param sinewavephase=((0.418879)) .alter .param sinewavephase=((0.523599)) .alter .param sinewavephase=((0.628319)) .alter .param sinewavephase=((0.733038)) .alter .param sinewavephase=((0.837758)) .alter .param sinewavephase=((0.942478)) .alter .param sinewavephase=((1.047198)) .alter .param sinewavephase=((1.151917)) .alter .param sinewavephase=((1.256637)) .alter .param sinewavephase=((1.361357)) .alter 67 .param sinewavephase=((1.466077)) .alter .param sinewavephase=((1.570796)) .alter .param sinewavephase=((1.675516)) .alter .param sinewavephase=((1.780236)) .alter .param sinewavephase=((1.884956)) .alter .param sinewavephase=((1.989675)) .alter .param sinewavephase=((2.094395)) .alter .param sinewavephase=((2.199115)) .alter .param sinewavephase=((2.303835)) .alter .param sinewavephase=((2.408555)) .alter .param sinewavephase=((2.513274)) .alter .param sinewavephase=((2.617994)) .alter .param sinewavephase=((2.722714)) .alter .param sinewavephase=((2.827434)) .alter .param sinewavephase=((2.932153)) .alter .param sinewavephase=((3.036873)) .alter .param sinewavephase=((3.141593)) .alter .param sinewavephase=((3.246313)) .alter .param sinewavephase=((3.351032)) .alter .param sinewavephase=((3.455752)) .alter .param sinewavephase=((3.560472)) .alter 68 .param sinewavephase=((3.665192)) .alter .param sinewavephase=((3.769911)) .alter .param sinewavephase=((3.874631)) .alter .param sinewavephase=((3.979351)) .alter .param sinewavephase=((4.084071)) .alter .param sinewavephase=((4.188790)) .alter .param sinewavephase=((4.293510)) .alter .param sinewavephase=((4.398230)) .alter .param sinewavephase=((4.502950)) .alter .param sinewavephase=((4.607669)) .alter .param sinewavephase=((4.712389)) .alter .param sinewavephase=((4.817109)) .alter .param sinewavephase=((4.921829)) .alter .param sinewavephase=((5.026548)) .alter .param sinewavephase=((5.131268)) .alter .param sinewavephase=((5.235988)) .alter .param sinewavephase=((5.340708)) .alter .param sinewavephase=((5.445427)) .alter .param sinewavephase=((5.550147)) .alter .param sinewavephase=((5.654867)) .alter .param sinewavephase=((5.759587)) .alter 69 .param sinewavephase=((5.864306)) .alter .param sinewavephase=((5.969026)) .alter .param sinewavephase=((6.073746)) .alter .param sinewavephase=((6.178466)) ********************************** .end 70 APPENDIX B Verilog-AMS Functions and Operators B.1 Mathematical Functions Table 1 Verilog-AMS Built-in Mathematical Functions Function Description Domain ln(x) Natural log x>0 log(x) Decimal log x>0 exp(x) Exponential x<80 sqrt(x) Square root x>=0 min(x,y) Minimum All x, all y max(x,y) Maximum All x, all y abs(x) Absolute All x floor(x) Floor All x ceil(x) Ceiling All x sin(x) Sine All x 71 cos(x) Cosine(x) All x tan(x) Tangent x !=n(π/2), n is odd asin(x) Arc-sine -1 <=x<=1 acons(x) Arc-cosine -1 <=x<=1 atan(x) Arc-tangent All x atan2(x,y) Arc-tangent x/y All x, y, except 0 hypot(x) Sqrt(x2+y2) All x, y sinh(x) Hyperbolic sine All x cosh(x) Hyperbolic cosine All x tanh(x) Hyperbolic tan All x asinh(x) a-hyperbolic sin All x acosh(x) a-hperbolic cos x >= 1 atanh(x) a-hperbolic tan -1<=x<=1 pow(x,y) Power xy If x>=0, all y, else int(y) 72 Table 2 Verilog-AMS Mathematical Operators Operator Description + , - , *, /, % Plus, minus, multiply, divide, modulus < , > , <= , >= , != =, = = =, != , = = Equality operators. (?:) ternary operator &&, ||, ~, &, |, ^, ^~ , ~^ Logical and bit-wise operators >>, << Shift operators B.2 Analog Operators Table 3 Verilog-AMS Built-in Analog Operators. Analog Operator ddt(x) Description Time Derivative of its argument. Usage y = ddt(x); idt(x) Time Integral of its argument. Usage y = idt(x) + c; Time Integral of its argument, passed through a modulus operation. It’s a periodic Integration. Time delay operator. Linear time delay for continuous waveforms Used for transmission line modeling. Last zero crossing. Returns time of last crossing of expr. idtmod(x) last_crossing(expr) transition(inp_sig, td, rt, ft) delay(expr, dt) Analog Transition filter. Filters piecewise constant waveforms to piecewise linear. Adds delay, rise time and fall time. 73 slew(inp_sig, slw_pos, slw_neg) laplace_zp(expr, num, dnom) laplace_zd(expr, num, dnom) laplace_np(expr, num, dnom) laplace_nd(expr, num, dnom) zi_zp(expr, num, dnom, T, trf, t0) zi_zd(expr, num, dnom, T, trf, t0) zi_np(expr, num, dnom, T, trf, t0) zi_nd(expr, num, dnom, T, trf, t0) Slew Filter. Used for smoothly varying signals. Bounds the signal rate-of-change to the output. Laplace filter Laplace analog operators provide different variants on specifying the filter coefficients to work in frequency domain. Use fixed poles and zeros. Z transform operator. These filters implement linear discrete-time filters using zeros and poles. T specifies the period of the filter. trf and t0 are optional transition times. B.3 Analog Event Driven Modeling The analog behavior of the module can be controlled using analog events. These events differ from the standard control flow constructs like if-else or case. Table 4 list the most common event commands that are be used. Event is called using the “@ (event)” syntax. Table 4 Common Verilog-AMS Analog Event Types. Analog Event Types cross (expr, dir) above(expr) Description Used for threshold and signal crossing. Signal low to high crossing. timer(time, delta-time) Used for periodicity or specific times. initial_step Event at the beginning of the simulation. final_step Event at the end of the simulation. 74 REFERENCES 1. Ken Martin, David Johns, “Analog Integrated Circuit Design,” John Wiley & sons, 1997. 2. Cheng, K., and JOU, K. F., “2.4GHz CMOS VCO Design with Verilog-AMS,” ICM 2003, pp 98-101, December 2003. 3. Thomas W Matthews, “On the effective sampling time of regenerative comparators,” IEEE International Midwest symposium on Circuits and systems, August 2008, pp. 638-641, vol. 1. 4. R. Sommer et. Al., “From System Specification to Layout: Seamless Top-Down Design Methods for Analog and Mixed-Signal Applications,” IEEE Proc. 2002 Design, Automation and Test, Europe, Conference and Exhibition. 5. Ken Kundert, “Principles of Top-Down Mixed Signal Design,” The Designers Guide community, www.designers-guide.org, 2003. 6. M. Wang, H. Maramis, D. Telian, and K. Chung, “New Techniques for Designing and Analyzing Multi-Giga Hertz Serial Links,” DesignCon 2005. 7. G. M. Yin, F. O. Eynde, and W. Sansen, "A high-speed CMOS comparator with 8-b resolution," IEEE Journal of Solid-State Circuits, vol. 27, pp. 208 - 211, February 1992. 8. Phillip E. Allen and Douglas R. Holberg, “CMOS Analog Circuit Design,” OXFORD, Second Edition, 2004. 75 9. Kenneth S. Kundert, Olaf Zinke, “Designers Guide for Verilog-AMS,” Kluwer Academic publishers, 2004. 10. Dan FitzPatrick, Ira Miller, “Analog Behavioral Modeling with the Verilog-A Language,” Kluwer Academic Publishers, Boston, Massachusetts. 1998. 11. Creating Analog Behavioral Models, Cadence, 2003. 12. Thomas W. Matthews and Perry L. Heedley, “A simulation Method for Accurately Determining DC and Dynamic Offsets in Comparators,” IEEE International Midwest Symposium on Circuits and Systems, 2005, pp. 1815-1818, vol. 2. 13. Thomas W. Matthew and Perry L. Heedley, private communication.