SOLIDS CONTROL

advertisement

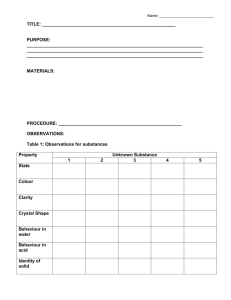

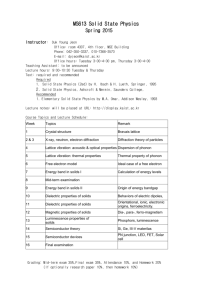

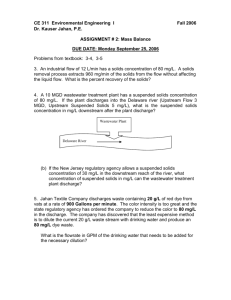

WASTE MANAGEMENT James M. Ebeling, Ph.D. Research Engineer Aquaculture Systems Technologies, LLC New Orleans, LA Solids Management Solids Capture – Quick Review • Effluent Treatment for: – – – – – Total Suspended Solids (TSS) Settleable Solids Biochemical oxygen demand (BOD5) Total Phosphorus (TP) Nitrogen • Total Ammonia Nitrogen (TAN) • Nitrate Nitrogen (NO3-N) – Pathogens Removed with solids Solids Capture – Quick Review • Gravity Separation • Settling Basins • Quiescent Zones • Off-line Settling Basins • Tube/Plate Settlers • Swirl Separators • Physical Filtration • Microscreen Filters (drum, disc, belt) • Granular Media Filters Solids Waste Characteristics Aquacultural Sludge Parameter Domestic Sludge Range Mean Range Typical Total Solids (%) 1.4–2.6 1.8 2.0–8.0 5.0 TVS (% of TS) 74.6–86.6 82.2 50–80 65 BOD5 (mg/L) 1,590–3,870 2,760 2,000–30,000 6,000 TAN (mg/L) 6.8–25.6 18.3 100–800 400 pH 6.0–7.2 6.7 5.0–8.0 6.0 Alkalinity 284–415 334 500–1,500 600 Solids Mass Balance Feed O2 CO2 Ammonia BOD, TSS, N, P Waste Management Overview • Treatment processes result in captured solids that must be managed: • Storage and Thickening • Thickening and Stabilization • Biosolids utilization and disposal • Stabilization of solids for pathogen destruction Solids Storage and Thickening Quiescent Zones Settling Basins Solids Storage and Thickening Earthen Ponds Solids Storage and Thickening • Slurrystore Tanks Engineered Storage Products Company Solids Thickening and Stabilization Captured solids require further dewatering: TSS Microscreen Filter Backwash 0.01-0.8% Quiescent Zone Siphon 3-5% Quiescent Zone Siphon 3-5% Solids Thickening • Solids must be thickened (dewatered) to reduce disposal costs/management. – Dewatering reduces sludge volume. – Sludge volume for 1,000 lb dry weight solids: – 12,000 gal – 2,400 gal – 1,200 gal – 800 gal 1% TSS 5% TSS 10% TSS 15% TSS Solids Thickening Methods • Processes to thicken clarifier/filter backwash solids: • offline settling basins (sludge thickening tanks) • wetlands or sand beds • coagulation/flocculation • belt filters • GeoTextile Bags Off-line Settling Basins • Designed for solids collection, thickening and storage • Intermittently loaded from – quiescent zone cleaning – filter backwashing – system cleaning Off-line Settling Basins Off-line Settling Tanks at Freshwater Institute Off-line Settling Basins Recirculating Aquaculture Systems Short Course Off-line Settling Basins LARGE structures with solids storage capacity Big Spring FCS (PA) Off-line Settling Basins Design Idaho DEQ (1998) design criteria for off-line settling basins: • • • • • • overflow rate of 0.0015 ft3/sec flow per ft2 surface area usually 3.5 ft deep usually built in pairs tank MUST capture 85% TSS TSS effluent CANNOT exceed 100 mg/L in 8 hr composite settleable solids effluent CANNOT exceed 1.0 ml/L in any sample Off-line Settling Basin Solids Removal • OPTION 1: Decant tank, harvest solids with backhoe or front end loader – Let solids dry for several days to 25% to 35% dry weight • OPTION 2: Sprinkler application to adjacent fields – 0.2% solids dry weight (after mixing solids) • OPTION 3: Decant tank, then pump out manure – 12% avg. solids dry weight – 20% max. solids dry weight – pumping method influences % solids removed Wetlands – Sand Beds Created Wetlands drying beds: • combine solids dewatering and disposal • sand drying bed planted with reeds • plants facilitate dewatering • loading • 30-60 kg dry solids per year per m2 area • 7-10 cm sludge at 2% solids every 7-21 days • series of beds receive sequential batches • store solids for 10 years Coagulation/Flocculation Coagulation Process of decreasing or neutralizing the electric charge on suspended particles Flocculation Process of bringing together the microfloc particles to form large agglomerations by the binding action of flocculants Recirculating Aquaculture Systems Short Course Suspended Solids Removal (Alum, Ferric Chloride, AMD) Alum in wastewater yields the following reaction: Al2(SO4)314 H2O + 3Ca(HCO3)2 3Ca SO4 + 2Al(OH)3 + 6CO2+ 14H2O Insoluble aluminum hydroxide is a gelatinous floc Ferric Chloride in wastewater yield the following reaction: 2FeCl3 6H2O+ 3Ca(HCO3)2 3CaCl2 +2Fe(OH)3 + 6 CO2 + 12H2O Insoluble ferric hydroxide is a gelatinous floc Recirculating Aquaculture Systems Short Course Phosphorus Removal (Alum, Ferric Chloride, AMD) Basic reaction: Al+3 + HnPO43-n AlPO4 + nH+ Fe+3 + HnPO43-n FePO4 + nH+ Simplest form of reaction, bench-scale test required to establish actual removal rate Recirculating Aquaculture Systems Short Course Coagulation/Flocculation Aids (Polymers) • charge neutralization (low molecular weight polymers) neutralize negative charge on particle • bridging between particles (high molecular weight polymers) long loops and tail connect particles Recirculating Aquaculture Systems Short Course Coagulation/Flocculation Aids (Polymers) Advantages: High Molecular Weight Long-chain Polymers • lower dosages requirements • reduced sludge production • easier storage and mixing • MW and charge densities optimized “designer” aids • no pH adjustment required • polymers bridge many smaller particles • improved floc resistance to shear forces Recirculating Aquaculture Systems Short Course Evaluation: alum/polymers Total Suspended Solids (mg/L) Polymer Optimum Dosage Raw sample Treated sample % Removal LT 27 0.8 mg/L 557 7 LT 7995 6 mg/L 859 E 38 3 mg/L A-120 Reactive Phosphorus (mg/L P) Raw sample Treated sample % Removal 99% 10 0.17 98% 10 99% 17 0.26 98% 1566 20 98% 34.8 0.57 98% 0.8 mg/L 654 7 99% 11.4 0.16 98% CE 834 5 mg/L 719 4 99% 13.7 0.27 98% CE 1950 5 mg/L 958 10 99% 17.1 0.35 98% Recirculating Aquaculture Systems Short Course Synergetic Effect of alum/polymers Percent Removal Turbidity (NTU) Optimal Dosage polymer polymer 50 mg/L alum / polymer 50 mg/L alum / polymer Magnafloc LT 7990 No Effect 8 --- 95.2% Magnafloc LT 7991 20 mg/L† 8 86.4% 95.3% Magnafloc LT 7992 20 mg/L 4 91.6% 95.4% Magnafloc LT 7995 10 mg/L 6 85.1% 96.3% Magnafloc LT 20 No Effect 0.8 --- 88.1% Magnafloc LT 22S 1.0 mg/L† 0.3 67.8% 94.8% Magnafloc LT 26 No Effect 0.8 --- 94.4% Magnafloc E 38 1.0 mg/L 3 45.1% 95.8% Ciba Specialty Chemicals Recirculating Aquaculture Systems Short Course Other WQ Effects of alum/polymers TAN NO2-N NO3-N TN CBOD5 COD (mg/L N) (mg/L N) (mg/L N) (mg/L N) (mg/L) (mg/L) Initial Sample 0.75 0.430 10.8 34 437.7 719 LT 27 0.32 0.218 3.6 4.8 17.8 36 LT 7995 0.28 0.216 3.7 4.4 8.1 21 E 38 0.24 0.224 3.7 4.7 12.0 27 A-120 0.36 0.222 3.6 4.3 17.7 29 CE 834 0.19 0.191 2.7 3.5 7.7 20 CE 1950 0.24 0.219 3.6 4.5 8.9 21 Recirculating Aquaculture Systems Short Course Belt Filter Coagulation/Flocculation Tank Recirculating Aquaculture Systems Short Course Belt Filter Belt Filter Recirculating Aquaculture Systems Short Course Belt Filter-Sludge • Alum • 13.2% ± 1.1 • Polymer • 11.6% ± 2.2 • Alum/Polymer • 12.6% ± 1.4 Recirculating Aquaculture Systems Short Course What is a Geotube ®? • Geotubes are constructed of Mirafi® high strength woven geotextile • Geotube ® containers are custom fabricated with seaming techniques that resist pressures during pumping operations. • High flow rate allows liquid to dewater, while containing solids. Recirculating Aquaculture Systems Short Course Benefits of Geotube® Technology • • • • • • • • Effective high volume containment. Efficient dewatering & volume reduction. Cost effective. No special equipment required. Custom site specific fabrication. Lower equipment cost. Low maintenance. Low labor cost. Recirculating Aquaculture Systems Short Course Containment Containment Dewatering Disposal Recirculating Aquaculture Systems Short Course Applications for Aquaculture Freshwater Applications • Winter Storage of Biosolids • Composting Marine Applications Tested by Miratech • Marine benthic waste • Marine fresh cage waste • Hatchery recirculation and pass through waste • Processing plant blood water • Biofouling waste from cleaning shellfish cages • Biofouling toxic waste (copper) from salmon net cleaning Recirculating Aquaculture Systems Short Course Research – Large Geobags • Each of the three bags were operated at a mean hydraulic loading rate of 58.7 Liters/day/m2 geotextile material. • Solids pumped to the bags for 0.5 minutes each hour (24/7). Recirculating Aquaculture Systems Short Course Results of Study Bag Influent Bag Effluent % Removal 1875 ± 811 98 ± 25 93.0 ± 3 Total Phosphorus (mg/l) 40.6 ± 16 12.7 ± 4.1 65 ± 12 Dissolved Reactive P (mg/l) Total Nitrogen (mg/l) 1.1 ± 0.7 10.8 ± 3.2 63.8 ± 25 37.9 ± 12 -1145 ± 574 32 ± 24 TAN (mg/l) 1.7 ± 0.6 28.1 ± 9.9 -1587 ± 490 cBOD5 (mg/l) 517 ± 241 309 ± 80 47 ± 15 TSS (mg/l) 36 Samples over 3 months Recirculating Aquaculture Systems Short Course Biosolids Utilization/Disposal • Composting • Land Application – Slurry (<1% solids) – Thickened Sludge (>5% solids) • Contract hauling Composting Composting Bin Composting Bin Cantrell Creek Trout Farm (NC) Land Application • Liquid/Slurry Application – Solids are easily transferred and distributed when they are >1% solids – Designed as a Slow Rate Land Treatment (crop irrigation) • Thickened Sludge Application – Designed as a soil amendment or fertilizer (as part of a crop nutrient management plan) – Applied from tanker trucks: surface spreading, incorporation, direct injection Land Application When the solids content is less than 1%, solids and slurries are easily pumped and distributed Contract Hauling Questions?