4387 - Fisher College of Business

advertisement

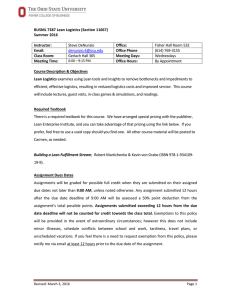

COURSE SYLLABUS BUSML 4387 – Lean Logistics Spring 2014 – Session 1 Instructor: Office: Office Hours: Primary Phone: E-mail: Thom Rogers Class Day & Time: Fisher Room 50 Location: By Appointment Credit Hours: 440-668-5172 rogers.1097@osu.edu Revised: December 30,2013 TR 7:05-8:25 PM (Session 1) Schoenbaum Room 200 1.5 Course Description & Prerequisites - Examines using Lean tools and insights to remove bottlenecks and impediments to efficient, effective logistics, resulting in reduced logistics costs and improved service. This course will include lectures, guest visits, in-class games & simulations, and readings. Prerequisites: BUSML 4380 Advanced Logistics Management; BUSMHR 2291 Applied Business Skills & Environment II Textbook – “Building a Lean Fulfillment Stream” by Robert Martichenko & Kevin von Grabe (ISBN 9781-934109-19-9). Sources: Your bookstores Architecture Library (1 copy) Amazon.com http://www.amazon.com/Building-Fulfillment-Stream-RobertMartichenko/dp/1934109193/ref=sr_1_1?ie=UTF8&qid=1364397246&sr=81&keywords=building+a+lean+fulfillment+stream Lean Enterprise Institute http://www.lean.org/BookStore/ProductDetails.cfm?SelectedProductId=272&ProductCategoryId=1 There will also be assigned readings from industry articles and journals, which will be posted on Carmen. Communication - OSU Carmen will be used as the primary source for class information and posting. Course Method - Classes will be conducted using an interactive format combining: class discussions, lectures, guest speakers, simulations/games, and text readings. Everyone is expected to participate in class and to prepare by reading the appropriate readings prior to the class meeting. Because of the participative nature of the class, attendance is critical and attendance will be taken. Excessive absences will be noted and will affect your participation grade. If you think you’ll miss class, please let instructor know in advance. Americans with Disabilities Act - If you have a disability, as defined by the Americans with Disabilities Act (ADA), which requires classroom/course accommodation or auxiliary aids, please inform me of your needs during the first week of class so that I can take appropriate action. Course Disclaimer - The schedule, policies, and assignments contained in this course syllabus or on the course website are subject to change in the event of extenuating circumstances, class progress, or by mutual agreement between the instructor and the students. General Course Instructions - All cellular phones, pagers and other electronic communication devices are to be turned off during class. Any electronic recording of the lecture or presentations is not authorized without prior approval by the instructor or guest speakers. The only exceptions will be those authorized in writing by the Office of Disability Services. Software and Industry Participants - When possible, we will be working with various companies to either learn about their processes, or to get hands-on experience with their software and tools. While all are leading commercial applications, the use of specific tools is for educational purposes and not meant as an endorsement of any one company or application. Likewise, statements made by guest speakers should not be construed as endorsements or opinions of The Ohio State University. Attendance Policy - Fisher College of Business strongly enforces University attendance policies. As per University rule 3335-8-33, any student may be disenrolled from a course for failure to attend by the first Friday of the term, or by the 3rd instructional day of the term, or by the second class meeting, whichever occurs first. For more on the rule, visit here: http://trustees.osu.edu/rules/university-rules/rules8/ru833.html Evaluation/Grading Criteria Final Exam – There will be a final exam, in our classroom, on the last day of our course. The exam will be composed of fifty (50) multiple choice questions, each worth six (6) points. The exam is worth a total of 300 points. Gemba Paper – Each student will pair up with another to prepare a paper. The two-person team must: Pick a business where a repeatable process is executed. Select a repeatable process on which to focus the paper. Observe, measure, and analyze the process and suggest improvements. The focal process can be industrial or routine. Complex processes are not essential. Rather, students should focus on a process that allows for direct observation, interviews with those performing the work, and measurement of inputs and outputs. Talk to/interview the people who execute the process; no one knows that process better than they do! A swim-lane process map must be used to capture the process work steps, and be included in the appendix. Swim-lane diagrams will be explained in class. Based on your observation and evaluation, offer suggestions on how the existing process might be made “leaner” and be improved, by eliminating waste. Feel free to share your findings with the people you interview. The paper will be at least two, and no more than four, pages in length (single-spaced, one-inch margins, 12-point font). An appendix consisting of tables and figures is permitted beyond the four-page maximum. This assignment is due at the start of class (in hard copy) on February 13. Should there be an odd number of students enrolled in the course, I will allow a very limited number of individuals to complete the paper assignment in trios or without a teammate. The bases for grading (and expectations) are the same for individuals as they are for team efforts. Also, should your partner drop the course, the remaining individual is responsible for the paper (unless we can identify another individual in the same situation and you wish to pair up). If you find you’re having trouble with your partner(s), let the instructor know as soon as possible; the day your paper is due is too late! The paper is worth 200 points. Class Participation – Class participation will be graded based on classroom and Carmen discussion, as well as quizzes if the instructor chooses to have any. Participation will be evaluated based on quality and frequency of participation. “Quality” is defined as factually correct, in-context and constructive. To encourage your participation each week, I will also review your activity on the discussion boards. Please note that participation in the discussion boards is not a substitute for class discussion, but it is a way to increase learning and dialogue around the reading and topics we discuss in class. Posting quality will be measured using the same guidelines as the class discussion. Your participation and performance on class quizzes (if any are given) will be combined for your class participation grade, with a maximum of 100 points possible for the course. Because class attendance and participation is important, missed quizzes (if any are given) may not be made up. Overall Grading Criteria & Scale Criteria Points Final Exam Gemba Paper Class Participation 300 200 100 600 Grading Scale Point Total 558 – 600 540 – 557 522 – 539 498 – 521 480 – 497 462 – 479 438 – 461 420 – 437 360 – 419 359 and Below Grade A AB+ B BC+ C CD E Schedule and Assignments (Subject to Change) Week Date Topic 1 1/7/14 1 2 1/9/14 1/14/14 Course Overview and Expectations Class Introductions The Lean Fulfillment Stream The Supply Chain Game, Part I 2 1/16/14 The Supply Chain Game, Part II 3 3 4 1/21/14 1/23/14 1/28/14 4 5 1/30/14 2/4/14 Getting Started and the Current State Envisioning the Future State Customer Collaboration & Outbound Logistics Case Study Lean In Action – A Real World Example 5 2/6/14 6 2/11/14 6 2/13/14 Shipping, Receiving, Trailer-Yard Management & Material Ordering Inbound Logistics & Supplier Collaboration Lean Logistics – Going Forward 7 2/18/14 Additional Lead Concepts 7 2/20/14 Final Exam – In Class NOTE: All guest speakers tentative and subject to change Guest Speaker (If Any) Assignment BLFS, Part 1 Eric Densmore – Senior Director, Lean Six Sigma, Bob Evans Foods Eric Densmore – Senior Director, Lean Six Sigma, Bob Evans Foods BLFS, Part 2 BLFS, Part 3 BLFS, Part 4 Case Study Eric Densmore and Scott Eder – Bob Evans Foods Rob Wright – Mast Global Logistics Doug Hartshorn – Roxane Labs BLFS, Part 5 BLFS, Part 6 BLFS, Part 7 Papers Due, Start of Class Dave Harry – Process Whisperer