OPS-LB-NM-029 Trace Asphaltenes Test (TAT) for Deasphalted Oil

advertisement

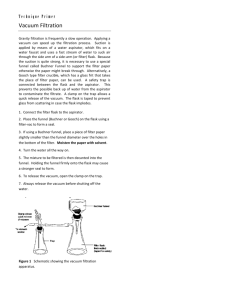

Trace Asphaltenes Test (TAT) for Deasphalted Oil Area 3 Job Hazards Unit Lab Yes Operating Procedure # OPS-LB-NM-029 Job Hazards Access and Egress Moving Parts Activities of Others Noise Adverse Weather Rail Movement Chemical Exposure Sharp Edges Electricity Slips, Trips, and Falls Fatigue Static Electricity Fire and Explosion Trip Injuries Ground Contamination Trapped Pressure Manual Handling Working at Height Certified by Revision # Date 09.20.2011 Scope / Objective Yes PPE Standard (SSP-0011) Page 1 of 1 Use Y Full Face Shield / Goggles Hood Clothing—Chemical Protection Gloves—Chemical Personal Fall Protection References / Documents Respirator / Filter Mask Supplied Air MSDS on gasoline. Unit Safe Upper & Lower Limits Spreadsheet Other: Equipment Materials and Reagents Special Instructions Environmental Trace Asphaltenes Test (TAT) for Deasphalted Oil 1 Place a pad of filter paper in an oven at about 105°C for 15 minutes. Cool in a desiccator and weigh to the nearest 0.1 mg. 2 For samples with results greater than 250 ppm of asphaltenes, the sample is to be hot filtered in inert atmosphere with a #40 Whatman filter paper (or equivalent) prior to the analysis. This will remove any extraneous materials that are not dissolved asphaltenes from the sample. 3 To the nearest 0.01 grams, weigh approximately 20 grams of DAO into the Erlenmeyer flask. Add 200 mls of n-Heptane and a magnetic stir bar to the flask. Attach the flask to the Allihn condenser and place on hot plate, start the stirrer. Turn the heat on so that the n-Heptane refluxes gently in the condenser. 4 Place the filter in the vacuum filtration apparatus and wet with 5 to 10 mls of n-heptane. When the DAO/n-heptane in the Erlenmeyer has refluxed for 20 minutes, stop the heat and stirring. Remove the stir bar and let the flask stand 10 minutes. 5 Filter the DAO/n-heptane through the vacuum filtration apparatus. While the flask is still warm, carefully wash the flask with two 20 ml washes of fresh n-heptane and filter the washings. Wash the filter with n-heptane until the washings are clear (usally three 10 ml washings are sufficient). It is very important that the filter be free of oil. 6 Place the filter in an oven at about 105°C for 15 minutes. Cool in a desiccator and weigh to the nearest 0.1 mg. Calculations: Calculate the amount of asphaltenes in the DAO as follows: Ppm wt. asphaltenes = (A-A’)/B X 1,000,000 wt% = (A – A’)/B X 100 Where: A is the filter weight after filtration. A’ is the filter weight prior to filtration. B is the weight of the sample. Report results to the nearest 1 ppm. Completed Date: Note: Prepared By: Approved By: This procedure is only valid at the time of printing. The control version can be found on the Meraux Refinery intranet.