Lean Repair & RL Strategic Trends

advertisement

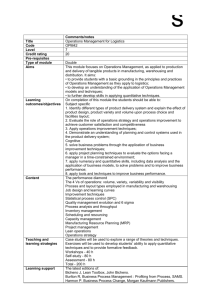

Lean Repair & RL Strategic Trends Workshop Amsterdam Gailen Vick President Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Welcome Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Today’s Presentation Trends in Reverse Logistics • Summary on forward logistics practices toward lean manufacturing Lean Repair • Why successful service providers will need to utilize lean practices • Summary of successful lean practices • Where to go from here • Getting Started in Lean Repair Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc What you should expect: Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Trends in Reverse Logistics Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Reverse Logistics is Really… Asset Management ! After-the-sale product management to maximize the product asset value and to minimize the cost of doing so. The aggressive management of assets or products. The objective is to make the fullest use of the product, to reduce the OEMs total program cost while ensuring the total satisfaction of the customer. Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Trend: Asset Management • OEMs are searching for companies that can manage overall product support cost reductions. • Introduce strategies to reduce warranty support inventory throughout the process. • Parts Harvesting reduces the cost of repair parts and warranty support. Sell / dispose of scrap. • End-of-Life product management, sales to secondary markets of White Label, refurbished or down-level products as an “add-on” service. Copyright © 2004 Reverse Logistics Trends, Inc. • Fulfillment capability is a plus. Copyright © 2008 Reverse Logistics Trends, Inc Trend: One-Stop Shop Reverse Logistics outsourcing will expand, while the number of companies will shrink. • OEMs are looking to reduce the number of 3PSPs they deal with. • “Turn-key” capabilities at the 3PSP provide a winning solution • Strategic alliances & partnerships with other 3PSPs, both Vertically and Horizontally. • Capability of “Supplier Management”. • Copyright © 2004 Reverse Logistics Trends, Inc. OEMs search 3PSPs that can manage “Closed Loop” processes and data sharing for process / product improvement. Copyright © 2008 Reverse Logistics Trends, Inc Trend: IT is critical • • • IT Capability and IT connectability will continue to grow in importance. Robust, Flexible IT services Prepare a 3-5 page overview of IT capabilities and reporting. • • • • Describe in-depth all current IT operations Describe IT Strategy with a 2-3 year plan Describe in ©detail the ITTrends, options available Copyright 2004 Reverse Logistics Inc. Provide sample reports. Copyright © 2008 Reverse Logistics Trends, Inc Trend: Repair Cost Squeeze • • • • With the decline of product cost repair activity will decline, screening activity will increase. OEMs will move screening “upstream” to reduce the logistics cost of moving good & bad product. Senior Management of OEMs push for quarterly cost reduction, RL is now being targeted. Continuously review of repair cost against: o o o o o Other Client programs Other regional vendors OEM cost of product Overall return costs (warranty mgt & logistics) © 2004 Reverse Logistics Trends, Inc. Offshore / Copyright Worldwide Vendors Copyright © 2008 Reverse Logistics Trends, Inc Trend: RFID–Changes Ahead • RFID usage is beginning to take hold. • Wal-mart, Department of Defense and NASA are leading the way in RFID usage. • Usage is only at the pallet or case level and only in forward logistics applications. • However, one-third of the US Retailers plan to invest in RFID technology in 2005. This includes investment ranging from preliminary investigation to hardware. • Zebra Technologies (printers) and SAP have jointly developed software and hardware for RFID. Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Trend: Electronics Everywhere • • • • Electronics/Storage Devices are finding new uses everywhere. Electronics will appear in devices where current service providers are not familiar with the technology. Field Service opportunities will expand, as well as local / regional repair & screening opportunities. Partnerships with unusual product service providers. Shorter life cycles of electronic devices will continue to accelerate – strong asset management will be required to support customer demanded warranties. Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Trend: Data Privacy “Data Privacy” concerns are coming to the forefront of the returns process for storage devices • End-of-Life requirement for the erasure of information on storage devices is coming from: • HIPAA( Health Insurance Portability and Accountability Act • State level (i.e.: Information Privacy Acts passed in North Dakota, Alaska, Connecticut, Illinois, Vermont, and California). • Public concern about Identity Theft • All parties must be concerned about the guarantees given Copyright © 2004 the Reverse methods Logistics Trends, Inc. to device owners and used in “sanitizing” a storage device. • Not all degaussers are created equal Copyright © 2008 Reverse Logistics Trends, Inc Trend: “Green Laws” • • • • • • Electronics recycling/disposal is coming to the forefront. The European Waste Electrical & Electronic Equipment (WEEE) Directive passed in 2003 will reach full effect in 2005 has major implications for Reverse Logistics companies and manufacturers. Reduction of Hazardous Substances (RoHS) European Member States will phase out identified Hazardous Substances by July 1, 2006. These European Directives have World Wide implications for OEMs and 3rd PSP’s. WEEE: • Effectively requires recycling; End-of–Life mgmt for OEMs. • OEMs seeking 3PSPs the can help solve the problem • Requires producers/third parties keep records on the mass of WEEE, components/materials/substances of products Copyright © 2004 Reverse Logistics Trends, Inc. ROHS: • Producers will be unable to sell non-compliant electronic products • Poor management may result in significant losses • “Lead-free” products is now impacting OEMs & 3PSPs Copyright © 2008 Reverse Logistics Trends, Inc Lean Repair Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Lean & the Repair Process The “Lean Manufacturing” concept comes from the attempt to conduct business with less human effort, floor space, materials, operation time and capital investment. One of the first books to describe Lean Manufacturing was “The Machine That Changed the World” (Womack, Jones, & Roos, 1990) Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Why Lean Repair? • Client pressure to reduce your price. • Focused on Client Needs • Reduces the Indirect Costs of Repair – Extra Inventory = Extra Cost (moving it) – Extra Inventory = Extra Space (storing it) • No Finished Goods (almost). • Reduces Process Times • Employee Involvement. Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Introducing Lean Repair At its highest level the Lean Process introduces the following elements into the business philosophy: – Value to the Customer – what processes add value to the product – Continuous Improvement – working towards the goal of “Perfection” – Focus on the Elimination of Waste – in all areas of the operation – Embodiment of JIT & Kanban practices Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Introducing Lean Repair The Main Tools of Lean Repair: • Pull / Kanban: Pull through, don’t push • Cellular Operations: don’t transport product • Quick Setup: Flexibility to meet demand • Value Stream Mapping: visualize change • Work Organization: process efficiency Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Lean Repair – Modern Mgmt. 8D Problem Solving Total Productive Maintenance Six Sigma Quick Setup “Jidoka” Problem Response Kaizen Blitz Teams Quality at the Supplier Value Stream Mapping Visual Controls Pull/ Kanban JIT Processes Work Organization Lean Repair 7 Wastes Cellular Process Copyright © 2004 Reverse Logistics Trends, Inc. Five Why’s Five S’s TAKT Time Copyright © 2008 Reverse Logistics Trends, Inc Balanced Flow One-Piece Flow Lean & the Repair Process Lean 7 Wastes: • Overproduction: producing more than is required or producing it before it is needed. • Waiting: during machine processing time. • Inventory or Work in Process (WIP): is material inbetween operations. • Process waste: asking why a specific processing step is needed • Material Handling: it should be minimized or eliminated Copyright © 2004 Reverse Logistics Trends, Inc. • Motion: (excessive) time to locate tools and parts • Making defective products: is a complete waste. Copyright © 2008 Reverse Logistics Trends, Inc Lean & the Repair Process The 5S philosophy: • Seiri - Sorting - Eliminating materials that do not need to be on the production floor • Seiton - Storage - Eliminating the time spent looking for things, locating tools, materials, and supplies in defined places • Seiso - Shining/Cleaning religiously maintain the work area and inspect tools & machinery while cleaning • Seiketsu - Standardize the work areas, so items out of place are obvious.Copyright © 2004 Reverse Logistics Trends, Inc. • Shitsuke – Make the above the normal routine. Copyright © 2008 Reverse Logistics Trends, Inc Lean & the Repair Process Kaizen Blitz Teams • 6-10 Members for 2-5 days focused on a specific area or process • Fast & Direct action creating immediate improvements and Lean momentum • Requires all levels of employees to be involved – assemblers, mgt., engineers • Teams need Champions to remove roadblocks to accomplishing objectives Copyright © 2004 Reverse Logistics Trends, Inc. • Produces intermediate steps to a long-term, overall Lean solution Copyright © 2008 Reverse Logistics Trends, Inc Batch Process vs. One-Piece Flow Transport time 12 minutes Step One 5 min. process/unit One Lot = 60 min. Step Two 5 min. process/unit One Lot = 60 min. Unit Time Total Time First Unit Processed Copyright © 2004 Reverse Logistics Trends, Inc. Batch 17 min 3h 24m 2h 29m Copyright © 2008 Reverse Logistics Trends, Inc Transport time 12 minutes Step Three 5 min. process/unit One Lot = 60 min. Batch Process vs. One-Piece Flow Step One Step Two Step Three 5 min. process/unit/step One Lot = 70 min. Unit Time Total Time First Unit Processed Batch 17 min 3h 24m 2h 29m Lean 15 min 70 min 15 min Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Less Material Less Handling FG Shippable Sooner Cellular Manufacturing Standard Plant Layout: Disassembly Disassembly occurs at first location • Operations laid out by operations specialty - “Classical” layout • Physical separation of process steps Transportation: time & headcount Assembly BGA Insertion BGA removed & replaced on PCBA at a second location Copyright © 2004 Reverse Logistics Trends, Inc. Final assembly occurs at Third location Copyright © 2008 Reverse Logistics Trends, Inc Cellular Manufacturing Disassembly BGA Insertion Disassembly occurs at first location BGA removed & replaced on PCBA at a second location Assembly Final assembly occurs at Third location Disassembly Disassembly occurs at first location Disassembly Assembly BGA Insertion BGA removed & replaced on PCBA at a second location Final assembly occurs at Third location Assembly Copyright © 2004 Reverse Logistics Trends, Inc. Disassembly occurs at first location Final assembly occurs at Third location Copyright © 2008 Reverse Logistics Trends, Inc Cellular Manufacturing Disassembly Assembly Disassembly BGA Insertion BGA removed & replaced on PCBA at a second location Disassembly Copyright © 2004 Reverse Logistics Trends, Inc. Disassembly Copyright © 2008 Reverse Logistics Trends, Inc Similar Products in Assembly Process Assembly Similar Products in Assembly Process Getting Started in Lean Repair Plan for Lean Repair • Form a Core Team • Study about Lean Manufacturing • Train the Core Team on Lean Manufacturing tools and processes • Research current conditions and processes • Determine target processes (for pilot runs) • Develop a roll-out plan & initial steps • Communicate the plan and get buy-in Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Getting Started in Lean Repair Roll-out of Pilot Projects • • • • • • • Intense preparation for initial projects Determine objectives and success metrics Communicate the plan to all Start with the 5S’s, mindful of the 7 Wastes Insert additional Lean elements as possible Analyze the results of the effort Adjust process for future projects Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Getting Started in Lean Repair Full Application of Lean Repair • • • • • • Review improved implementation plan Train more personnel in Lean techniques Target complete processes for Lean Repair Communicate to all personnel Initiate Lean Repair throughout the plant Take second look at work previously done, begin second phase of improvement • Analyze the results Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Getting Started in Lean Repair Lean Repair On-going • Educate and Involve all Employees • Continue to add “Layers” of Lean Repair methodology and techniques, like 6 Sigma, TPM and smaller Kanbans • Push JIT and On-demand requirements out to suppliers and service providers • Formally Analyze results and improve strategy – with all participating Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Getting Started in Lean Repair Communicate Often & Celebrate Successes Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Getting Started in Lean Repair Consider beginning with: • The 5Ss • Kaizen teams • Value Stream Mapping • Demand/Pull Systems • Visual Management of the work flow And a well thought out plan with ALL levels of employees involved. Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Lean Repair Flow Highly Variable Incoming Stock to Level: Tag & Box remainder Kanban Products enter into Continuous Flow Process Continuous Flow Pull Signal Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Min/Max Kanban to signal movement into Continuous Flow FG Ship Final Notes Traditional Lean Result Batch Process or Process all to Finished Goods One-Piece Flow – meeting customer requirements Potential loss of Revenue, but increase in productivity Central Planning – all stages of production Decentralized/ Pull Demand More responsiveness, “automatic” planning Order variation managed at the Finished Goods level Order variations managed at the process level Smaller FG, less rework, flexible process Process Simplification, localized knowledge Process Enhancement, cross-departmental teams Knowledgeable, involved work force, investment in training Copyright © 2004 Reverse Logistics Trends, Inc. Supplier Controlled Materials Delivery Process Controlled Materials Delivery Copyright © 2008 Reverse Logistics Trends, Inc Reduced inventory, expenditure, Up-to-date revisions Final Notes • Lean manufacturing forces the mfg team to address issues (defects, no parts, etc.) that might otherwise be hidden by batch manufacturing. • Consigned Parts: Client may appreciate a “leaner” approach to inventory (cost reduction). • Pick Pilot projects to prove the theory. It may take 6 months to years to implement. • Set up metrics to measure the before and after contributing costs before beginning a project. • Employee involvement must be carefully considered at each step of Lean implementation. Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc Final Notes – The Math Value of Lean Repair: + + + + + $$$+ In-Process Inventory Unit Reduction Process Time Reduced Reduction of Non-Value Adding Steps Reduction in Planning Requirements Less Investment in Old Products/Process Training and Startup Costs New Setup, Fixtures, Equipment Costs Copyright © 2004 Reverse Logistics Trends, Inc. Significant On-going Savings Copyright © 2008 Reverse Logistics Trends, Inc Thank You Copyright © 2004 Reverse Logistics Trends, Inc. Copyright © 2008 Reverse Logistics Trends, Inc