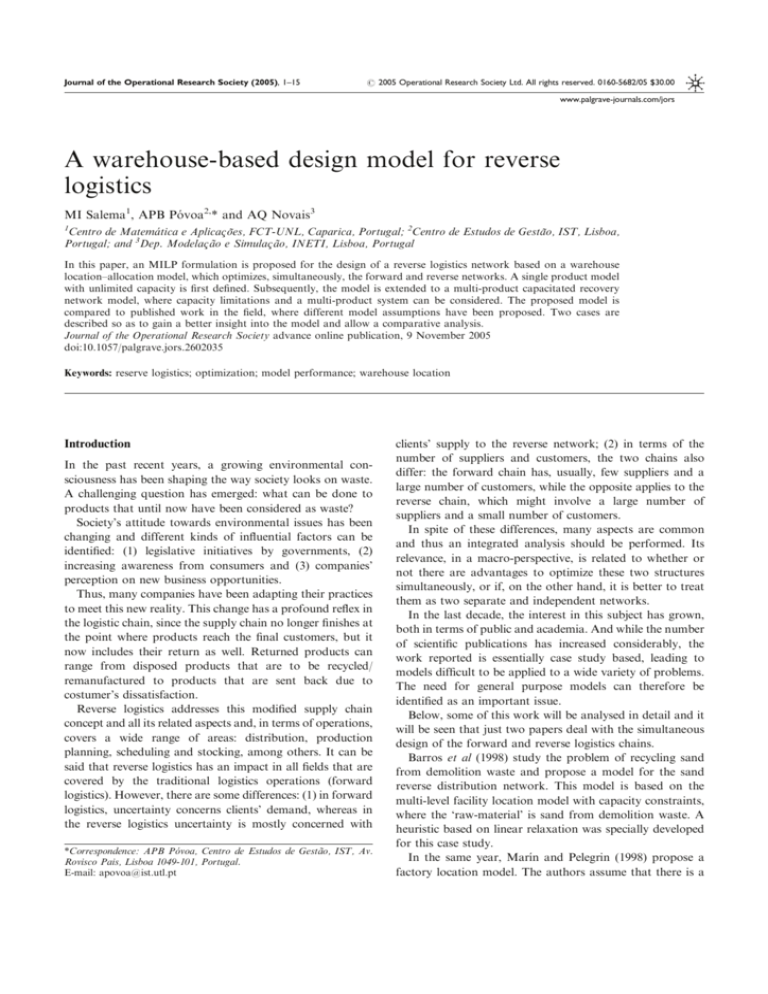

Journal of the Operational Research Society (2005), 1–15

r 2005 Operational Research Society Ltd. All rights reserved. 0160-5682/05 $30.00

www.palgrave-journals.com/jors

A warehouse-based design model for reverse

logistics

MI Salema1, APB Póvoa2,* and AQ Novais3

1

Centro de Matemática e Aplicac¸ões, FCT-UNL, Caparica, Portugal; 2Centro de Estudos de Gestão, IST, Lisboa,

Portugal; and 3Dep. Modelac¸ão e Simulac¸ão, INETI, Lisboa, Portugal

In this paper, an MILP formulation is proposed for the design of a reverse logistics network based on a warehouse

location–allocation model, which optimizes, simultaneously, the forward and reverse networks. A single product model

with unlimited capacity is first defined. Subsequently, the model is extended to a multi-product capacitated recovery

network model, where capacity limitations and a multi-product system can be considered. The proposed model is

compared to published work in the field, where different model assumptions have been proposed. Two cases are

described so as to gain a better insight into the model and allow a comparative analysis.

Journal of the Operational Research Society advance online publication, 9 November 2005

doi:10.1057/palgrave.jors.2602035

Keywords: reserve logistics; optimization; model performance; warehouse location

Introduction

In the past recent years, a growing environmental consciousness has been shaping the way society looks on waste.

A challenging question has emerged: what can be done to

products that until now have been considered as waste?

Society’s attitude towards environmental issues has been

changing and different kinds of influential factors can be

identified: (1) legislative initiatives by governments, (2)

increasing awareness from consumers and (3) companies’

perception on new business opportunities.

Thus, many companies have been adapting their practices

to meet this new reality. This change has a profound reflex in

the logistic chain, since the supply chain no longer finishes at

the point where products reach the final customers, but it

now includes their return as well. Returned products can

range from disposed products that are to be recycled/

remanufactured to products that are sent back due to

costumer’s dissatisfaction.

Reverse logistics addresses this modified supply chain

concept and all its related aspects and, in terms of operations,

covers a wide range of areas: distribution, production

planning, scheduling and stocking, among others. It can be

said that reverse logistics has an impact in all fields that are

covered by the traditional logistics operations (forward

logistics). However, there are some differences: (1) in forward

logistics, uncertainty concerns clients’ demand, whereas in

the reverse logistics uncertainty is mostly concerned with

*Correspondence: APB Póvoa, Centro de Estudos de Gestão, IST, Av.

Rovisco Pais, Lisboa 1049-101, Portugal.

E-mail: apovoa@ist.utl.pt

clients’ supply to the reverse network; (2) in terms of the

number of suppliers and customers, the two chains also

differ: the forward chain has, usually, few suppliers and a

large number of customers, while the opposite applies to the

reverse chain, which might involve a large number of

suppliers and a small number of customers.

In spite of these differences, many aspects are common

and thus an integrated analysis should be performed. Its

relevance, in a macro-perspective, is related to whether or

not there are advantages to optimize these two structures

simultaneously, or if, on the other hand, it is better to treat

them as two separate and independent networks.

In the last decade, the interest in this subject has grown,

both in terms of public and academia. And while the number

of scientific publications has increased considerably, the

work reported is essentially case study based, leading to

models difficult to be applied to a wide variety of problems.

The need for general purpose models can therefore be

identified as an important issue.

Below, some of this work will be analysed in detail and it

will be seen that just two papers deal with the simultaneous

design of the forward and reverse logistics chains.

Barros et al (1998) study the problem of recycling sand

from demolition waste and propose a model for the sand

reverse distribution network. This model is based on the

multi-level facility location model with capacity constraints,

where the ‘raw-material’ is sand from demolition waste. A

heuristic based on linear relaxation was specially developed

for this case study.

In the same year, Marı́n and Pelegrin (1998) propose a

factory location model. The authors assume that there is a