Pravin Sharma Samip Subedi David Mikkel Hansen

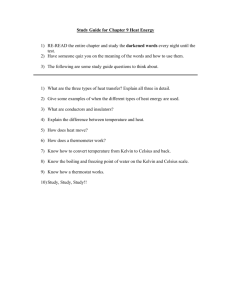

advertisement

Time Calculation of the Temperature Rise in an Electric Iron Objectives: To calculate the time required by an electric iron to raise the temperature from the room temperature to 65 degree Celsius. We first measured three sets of data experimentally and then compared the data to the value that we calculated though our assumptions. Equipment used Proctor SileX Iron (model #17400) Stopwatch Thermocouple Vernier Caliper Iron & Vernier Caliper Thermocouple Problem: We want to calculate the time required for thetemperature rise to 65 degree Celsius (final temperature of the electric iron after heating) from 23 degree Celsius (initial temperature of the iron before heating). We assumed to have heat transfer as convention and radiation. The heated plate of electric iron is assumed to be Aluminum Alloy 195, cast(4.5 % Cu). The properties of the aluminum alloy were noted at 300K from the ‘Fundamental of Heat and Mass transfer’ book. Density(rho)=2790 kg/m^3 C=883 J/kg.K K=168 W/m.K Assume emissivity( ) =0.80 T(surf)=22 Degree Celsius Tf=65 Degree Celsius Area of the aluminum plate(approx.) =0.02m^2 Power rated of electric iron=1200W Solution Assuming efficiency to be 50%, For a 1200W electric Iron; q =0.50*1200=600W; Uniform heat flux (qꞌꞌ) =600/0.02= 3*10^4 W/m^2 Let convention coefficient at outer surface be (h)=10W/m^2.K Bi=h L/K=10*0.00235/168=1.4*10^-4 For radiation, =0.8*(5.67*10^-8)(338+295)*(114244+87025) =5.779 W/m^2.K Bi r =hr L/k=5.779*0.00235/168=8*10^-5 Continue….. Using the lumped capacitance analysis, we have; With Eg =0, we can write the equation as, Solving in Matlab, we get; t = 39 sec. Experimental data: From the experiment, we found that the required time for the raise in temperature to 65 Degree Celsius from room temperature of 22 degree Celsius were 26, 28 and 25 seconds respectively in three consecutive experiments, which is close to the value we calculated. Now the average of the three experimental data is 26.33 s. =(39-26.33)/26.33*100 =48.12% Conclusion and Recommendation: The percentage error that we calculated was reasonable considering our assumptions in the calculation model. If possible get all the necessary data from the manufacturer so that the error associated with modeling the calculation will be minimal. Possible Reasons of Error The assumption of the material properties of the ironing surface. The assumption of the efficiency of the iron. Human error associated with reading the time and temperature rise. The assumption of uniform heat flux. The calculation of the surface area of ironing surface. References http://laundry.manualsonline.com/manuals/mfg/ham ilton_beach/14700.html?idRes=12120817 Incropera (2006) Fundamentals of Heat and Mass Transfer http://eartheasy.com/live_energyeffic_appl.htm