Process Strategy

advertisement

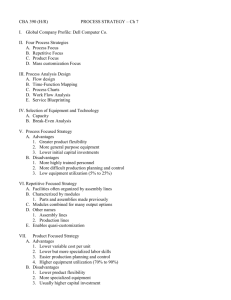

Operations Management Chapter 7 – Process Strategy PowerPoint presentation to accompany Heizer/Render Principles of Operations Management, 6e Operations Management, 8e © 2006 Prentice Hall, Inc. Hall, Inc. © 2006 Prentice 7–1 Process, Volume, and Variety Volume Figure 7.1 Low Volume High Customization Medium Customizatio n Low Customization © 2006 Prentice Hall, Inc. Repetitive Process Process Focus projects, job shops (machine, print, carpentry) High Volume Mass Customization (difficult to achieve, but huge rewards) Dell Computer Co. Repetitive (autos, motorcycles) Harley Davidson Product Focus (commercial baked goods, steel, glass) Nucor Steel 7–2 Process Focus Facilities are organized around specific activities or processes General purpose equipment and skilled personnel High degree of product flexibility Typically high costs and low equipment utilization Product flows may vary considerably making planning and scheduling a challenge © 2006 Prentice Hall, Inc. 7–3 Repetitive Focus Facilities often organized as assembly lines Characterized by modules with parts and assemblies made previously Modules may be combined for many output options Less flexibility than process-focused facilities but more efficient © 2006 Prentice Hall, Inc. 7–4 Product Focus Facilities are organized by product High volume but low variety of products Long, continuous production runs enable efficient processes Typically high fixed cost but low variable cost Generally less skilled labor © 2006 Prentice Hall, Inc. 7–5 Comparison of Processes Process Focus Repetitive Focus Product Focus Mass Customization (Low volume, high variety) (Modular) (High-volume, low-variety) Small quantity, large variety of products Long runs, standardized product made from modules Large quantity, small variety of products Large quantity, large variety of products General purpose equipment Special equipment aids in use of assembly line Special purpose equipment Rapid changeover on flexible equipment (High-volume, high-variety) Table 7.2 © 2006 Prentice Hall, Inc. 7–6 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Operators are broadly skilled Employees are modestly trained Operators are less broadly skilled Flexible operators are trained for the necessary customization Many job instructions as each job changes Repetition reduces training and changes in job instructions Few work orders and job instructions because jobs standardized Custom orders require many job instructions Table 7.2 © 2006 Prentice Hall, Inc. 7–7 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Raw material inventories high JIT procurement techniques used Raw material inventories are low Raw material inventories are low Work-inprocess is high JIT inventory techniques used Work-inprocess inventory is low Work-inprocess inventory driven down by JIT, lean production Table 7.2 © 2006 Prentice Hall, Inc. 7–8 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Units move slowly through the plant Movement is measured in hours and days Swift movement of unit through the facility is typical Goods move swiftly through the facility Finished goods made to order Finished goods made to frequent forecast Finished goods made to forecast and stored Finished goods often made to order Table 7.2 © 2006 Prentice Hall, Inc. 7–9 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Scheduling is complex, trade-offs between inventory, availability, customer service Scheduling based on building various models from modules to forecasts Product Focus (High-volume, low-variety) Relatively simple scheduling, establishing output rate to meet forecasts Mass Customization (High-volume, high-variety) Sophisticated scheduling required to accommodate custom orders Table 7.2 © 2006 Prentice Hall, Inc. 7 – 10 Comparison of Processes Process Focus Repetitive Focus (Low volume, high variety) (Modular) Product Focus (High-volume, low-variety) Mass Customization (High-volume, high-variety) Fixed costs low, variable costs high Fixed costs dependent on flexibility of the facility Fixed costs high, variable costs low Fixed costs high, variable costs must be low Costing estimated before job, not known until after job is complete Costs usually known due to extensive experience High fixed costs mean costs dependent on utilization of capacity High fixed costs and dynamic variable costs make costing a challenge Table 7.2 © 2006 Prentice Hall, Inc. 7 – 11 Mass Customization The rapid, low-cost production of goods and service to satisfy increasingly unique customer desires Combines the flexibility of a process focus with the efficiency of a product focus © 2006 Prentice Hall, Inc. 7 – 12 Mass Customization Table 7.1 Item Vehicle models Vehicle types Bicycle types Software titles Web sites Movie releases New book titles Houston TV channels Breakfast cereals Items (SKUs) in supermarkets © 2006 Prentice Hall, Inc. Number of Choices Early 21st Early 1970s Century 140 260 18 1,212 8 19 0 300,000 0 46,412,165 267 458 40,530 77,446 5 185 160 340 14,000 150,000 7 – 13 Changing Processes Difficult and expensive May mean starting over Important to get it right © 2006 Prentice Hall, Inc. 7 – 14 Process Analysis Tools Flowcharts provide a view of the big picture Process diagrams show detail Service blueprint focuses on customer interaction © 2006 Prentice Hall, Inc. 7 – 15 Service Blueprint Focuses on the customer and provider interaction Defines three levels of interaction Each level has different management issues Identifies potential failure points © 2006 Prentice Hall, Inc. 7 – 16 Service Blueprint Personal Greeting Level #1 Service Diagnosis Perform Service Customer arrives for service Warm greeting and obtain service request Customer departs Determine specifics No Standard request Level #2 Friendly Close Direct customer to waiting room Can service be done and does customer approve? Yes Level #3 Potential failure point Yes Notify customer and recommend an alternative provider Customer pays bill No Notify customer the car is ready Perform required work Prepare invoice Figure 7.9 © 2006 Prentice Hall, Inc. 7 – 17