From A to A+ - Amazon Web Services

advertisement

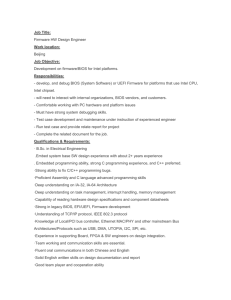

ADLINK Remote devices Embedded Tech Con 2015 Matthias Huber Jun 08 2015 1 Company Profile Establishment August, 1995 Chairman/President Jim Liu / Daniel Yang Headquarters Taipei, Taiwan Ownership Publicly listed since 2002 Listing TAIEX: 6166 Revenue US$219M (Y2013), US$265M (Y2014) Employees 1,556 (May. 2014) Branch Offices USA, Germany(2), France, Singapore, India, China (BJ, SH, SZ), Korea, Japan, Israel Capital/Mkt Cap. US$57M / US$ 460M Worldwide Offices and Headcount Research & Development Centers Sales / Support Offices Manufacturing Site San Jose Mannheim Munich Seoul Beijing Tokyo Shanghai Shenzhen Taipei Headquarter Bangalore Singapore 415 R&D Engineers 195 is SW Engineers Total Employees: 1556 3 Core Strategic Vision A world-class Provider of Application-Ready intelligent Platforms(ARiP) for . Measurement/Automation, . Communications, . Medical, . Transportation/Military, . Infotainment Applications Application Ready Intelligent Platforms ADLINK IoT solutions Building blocks for Intelligent devices Ready to use Intelligent devices IoT Gateways Smart Embedded Management Agent cloud connectivity for monitoring and management MCPS Product Lines Building Blocks Building Blocks COMExpress Q7 SMARC Applications ETX Medical Industrial Automation COM (Computer-On-Modules) PC/104-Plus, PC/104-Express PC/104 Communication Transportation Military Transportation 7 MCPS Product Lines Building Blocks & Intelligent Middleware Building Blocks Applications Lottery Infotainment Vending Security Vending / Lottery Mini-ITX SEMA Intelligent Middleware SEMA-cloud Industrial IoT I/O Application Ready SEMA Remote Monitoring SEMA cloud – internet monitoring and control 8 MAPS Product Focus Building Blocks & Applications Building Blocks / Application-Ready Platforms Measurement Automation •PXI Platforms •High-Speed Digitizers •Dynamic signal Digitizers •High-speed DIO •USB/PCIe/PCI DAQ •Motion controllers •x86 smart camera & vision systems •Frame grabbers •Distributed I/O & motion I/O Platform •Vertically focused Fanless I/O Platforms •PICMG1.3 SBC and industrial IMB •Industrial chassis Handheld • Semi-rugged handheld devices • Android /Windows OS Applications Test & Measurement Machine/Factory Automation Intelligent Transportation 9 DCPS Product Portfolio Vertical Markets Medical Industrial Automation Logistics Products Medical PC& Medical Monitors • High performance, fanless operation • Easy-to-clean, full IP65 metal housing • EN60601 certification • Multitouch P-CAP Industrial PC and Industrial Monitors • IP69k stainless/IP65 aluminum housing • Easy-to-configure CPU (X86 or ARM) • Easy-to-customize I/O ports • P-CAP and Resistive touch options • Windows, Linux, Android Rugged Tablet Computers Vehicle-mount docking kit • Sunlight readable display • Rugged design • Long battery life • Windows/Android Diagnostics / on board Smart Embedded Management Agent March 2013 Smart Embedded Management Agent SEMA is a set of embedded functions used on the newer versions of ADLINKs products SEMA consists of • • • • • Board Management Controller Board Debug Tools Embedded BIOS Extensions API Library Application Software (CLI, GUI, http) SEMA is a set of deeply embedded functions build into all ADLINK modules to enhance end user embedded systems reliability and offers support during initial system integration and customer carrier bring up. Board Controller Overview The core of the system is an onboard MCU with firmware 100% developed in-house by the Lippert by ADLINK team Hardware Abstraction • All embedded functions are included in a single part that is the same for all ADLINK modules ensuring compatibility between product generations Always Accessible • Do you need to know, online and immediately, what is happening with your remote system? SEMA offers access to the your modules embedded features via Command Line, GUI and even WEB browser SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Watchdog Timer Watchdog Function • A watchdog timer (WDT) is a hardware timer that automatically generates a system reset if a software application program neglects to periodically reset it. It is often used to automatically reset an embedded device that hangs because of a software or hardware fault. SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Operation • After System start the Watchdog can be automatically enabled with a startup value from Flash memory. • The timeout value is given in seconds and has a 16-bit (two byte wide) size. So the Timeout of the Watchdog can be set to 165535 seconds. 0 disables the Watchdog Module Info and Statistics Board Info The following information is stored in the BC : • Board name • CPU type and amount and type of RAM • BIOS version • Part Number • Serial Number • Product test date • LAM MAC ID • BC bootloader and firmware revisions • Repair information Runtime Statistics • The total system uptime in hours and minutes. • Uptime since last boot, hrs /min / sec • Number of power cycles. • Boot cycles, HW / SW-Reset and Power-ups. • Last Boot reason SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control I2C Controller Free High Speed I2C • In addition to the SMbus supplied by the main chipset of the module a free for use high speed I2C is supported on the SEMA board controller. The I2C supports multi master mode and 100/200 or 400 kHz operation. • The SEMA Board controller and I2C bus are both powered by the standby-power domain allowing operation during power down and suspend states. SEMA Board Controller Watchdog Module Info & Stats I2C I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Failure Forensics Status Indicator LED • The BC status LED can signal system state changes and power-up failures. A blink code will be displayed in case of a failure. • System state changes : HW-Reset, SWReset, Power-Up, Power-Down, ResetButton and Power Button activity. • Power-up failures : the LED flashing code can signal a corrupted BIOS, failures at the onboard power supply or the module hanging while waiting for a Power OK due to problem with supply power or power sequence. Last State • Forensic information available after system or module failures include Min-/Maxtemperature of CPU and system, cause of the last system restart and latest measurement of voltages on the module. All which can be used to analyze the system or module failure. SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Flash Storage User Data • The BC provides 512 for normal end user data This memory areas is independent from the BIOS and not cleared or restored during BIOS updates, which makes it perfect to store serial numbers, keys, configuration data and other sensitive or board specific information. Secure Area • The SECURE area is 128 bytes in size and used to store critical data such as secure key codes. It can be protected through a one-time programmable hardware fuse to provide a maximum of security. • This area may be compared to similar features such as Trusted Platform Modules (TPM) or SIM cards. Attach a unique key to your system and prevent your data from read or copied without your permission. SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Flat Panel Control Backlight Control • To suppress the BIOS screen appearing on the screen during boot the BC can inhibit the BKL_ENABL signal. It can either relase it after POST or inhibit indefinitely after which on OS level an API command can release the signal Brightness Control • Settings the PWM source for brightness control can be done in the BIOS. Sources are the - the integrated Graphics Core - the Board Controller’s own PWM output - a discrete PWM controller on the carrier . • Startup brightness intensity can be selected in the BIOS SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Fail Safe BIOS Dual SPI BIOS • Two identical BIOS are located on every board. One active an one continuously standing by. • If through accidental corruption of the first BIOS the system becomes unbootable the BC detects this problem RESETs the system and permanently switches over to the secondary backup BIOS Fully compatibility • The failsafe BIOS implementation is fully compatible with the PICMG COM.0 specification that allows an SPI BIOS to be located on the carrier or on a module. SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Temperature Monitor & Fan Control CPU / System Temperatures • Monitors temperature sensor readings of CPU and board temperature. Hardware Monitor Logging • When the SEMA GUI application is running the CPU and System temperature are queried every second (temperatures, power consumption etc.) and can optionally be written to a log file. The data is written as plain ASCII text in TAB separated columns and therefore can easily be imported into any spreadsheet calculation program or other data processing tools. FAN Control • The BC has its own PWM fan out output can automatically relates measured CPU temperature to the PRM of the Fan just like a normal smart fan controller SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Temperature Monitor & Fan Control Control Fan Power Monitor & Control Power Monitor & Control Monitor System Voltages • All on board created voltages are transformed by a 10 bit AD converter and stored in 8 separate registers retrievable by the user. SEMA Board Controller Watchdog Module Info & Stats I2C Controller Failure Forensics Flash Storage Flat Panel Control Fail Safe Dual BIOS Temperature Monitor & Fan Control Power Monitor & Control Current Power Consumption • By using a Shunt, the total supply current to the module can be read. Based on the information, the momentary power consumption can be calculated. Power Sequence Control • The BC controls the power on process and can report any failure detected. This is a great feature during a customer’ carrier bring up • AT power mode is supported by detecting monitoring the supply voltages Deep S5 power saving • When powered by an ATX Power Supply or Battery that supplies standby voltage during S5, the SEMA BC can automatically switch of 5Vsb to the rest of the module to safe power. 2.0 Remote Management, Analytics and Configuration Having a Look at the IoT Industry Market Trend (1) Downtime: The worst thing that can happen! If the Machine is out of order: It can‘t do what it should No money comes in Reputation may be loss Fixing the issue may take hours to days Downtime is not acceptable! How to avoid it? SEMA: Smart Embedded Management Agent SEMA = Hardware + Software 8bit uC, 64 IOs API Application What is SEMA Cloud? The Idea of Embedded Connectivity • • • • Make your systems available anywhere at anytime Make your systems easily maintainable Be always informed about your systems health and status Be proactive to minimize system downtime SEMA Cloud 2.0 ADLINK‘s Device to Cloud Solution Group all your Devices Assign Thresholds to any kind of Data Assign Alerts when Thresholds are crossed Assign Notifications or Actions to Alerts Your Sensor Data 01011100 1 Local Agent Your Device Cloud Service Web Portal SEMA Cloud 2.0 More than „just“ a Cloud • SEMA Cloud is the Data Carrier on your Device – TLS secured TCP/IP connection to the Cloud – Carrier for any kind of data – SEMA ready. Use ADLINK‘s Smart Embedded Management Agent to manage all your devices through the Cloud • SEMA Cloud is the Server Farm spanning up the Cloud – Store the data from the field clients – Processes the client data (thresholds, alarm, notifications, actions) • SEMA Cloud is the End Application to Manage your Devices – Securly access all devices through one Web Portal SEMA Cloud 2.0 New Features 2015 – M2M Agent • M2M Agent – Client OS Support • Available for Linux x86 / ARM (32/64bit) • Available for Windows x86 (32/64bit) • Android x86 / ARM (32/64bit) on the move – Client Configuration • • • • HTTP TR50 Interface MQTT Interface TLS 1.2 Data Encryption Business Rule Processor (download configuration from online protal and run (supervise) locally) • Not-always connected mode (2G / 3G / 4G ready) • Connection drop recognition (store data until connection is back and retransmit) • File transfer (e.g. BIOS) – Software Development Kit • Available to input custom data SEMA Cloud 2.0 New Features 2015 – Data Server • Data Server – Servers in all 3 geographies: • The Americas: North Virginia • Europe: Ireland • Asia: Japan – Features • • • • • • – Connection Management Device Management Alert Notifications Rating Engine Reporting Engine MQTT Broker Revenue Enhancer (optional) • Enterprise connection (e.g. SAP, SQL) SEMA Cloud 2.0 New Features 2015 – Online Portal • Online Portal – – – – Ready for File Transfer (e.g. BIOS) Ready for SEMA interaction (e.g. protect / configure groups of devices by a few clicks using SEMA calls) Ready for location tracking Ready for campaign management What is the Benefit of SEMA Cloud? Reducing the Total Cost of Ownership (TCO) Local FW Update (5min) Cloud FW Update (5min) Example: 1000 Devices, 4 FW Updates / Year Example: 1000 Devices, 4 FW Updates / Year = Multiple Technicians travel and update on site = 1000 Devices x 4 Updates x 50€ = One Technician updates all devices at once by remote = 200.000€ / Year = less than 50€ / Year The Architecture of SEMA Cloud Business Rules „Combine monitoring functions through events with actions“ CPU Temperature Throttle CPU System Temperature Call Watchdog HDD Status Thresholds Toggle GPIO CPU Frequency Turn on FAN Fan Speed Send SMS GPIO Level Turn off System Custom Input Custom Action Use Cases / Scenarios Retail (Vending) Analyse Customer Needs Submit Products sold X Refill Change Product Portfolio Use Cases / Scenarios Industrial Automation (Factory Automation) Analyse Data in Realtime Re-Configure Machines remotely Access Factory Data globally Report Data Take Control Use Cases / Scenarios Transportation (In-Vehicle-Computing) Analyse Data 2G / 3G / LTE GPIO LVDS COM / USB GPS Emergency Button Internet / Touch Panel / Information Card Reader / Receipt Printer Geo Location Security Information Transaction Tracking • Improve Routes • Schedule Maintenances • Remote Updates Use Cases / Scenarios Medical (Healthcare) Recall Data Anytime Smart Pills Analyse History Blood Pressure Diabetes Care Share with Doctor SEMA Cloud 2.0 The Dashboard SEMA Cloud 2.0 Location Tracking SEMA Cloud 2.0 Events / Files / Methods Get Transfer files Take Seegeneric what action is to information your immediately goingsystem on in your about your system Set actions system immediately SEMA Cloud 2.0 Developer Configuration – SEMA Feature Interaction (2) (3) (1) (4) (5) (6) Example FAN Trigger: 1. Select Trigger 2. Create Trigger 3. Start Trigger 4. Define alert feature (= CPU Temperature) 5. Define alert value (Greater than 55) 6. Define action (set fan to 100%) Thank You Q&A