DHW Advanced Energy April 2014

advertisement

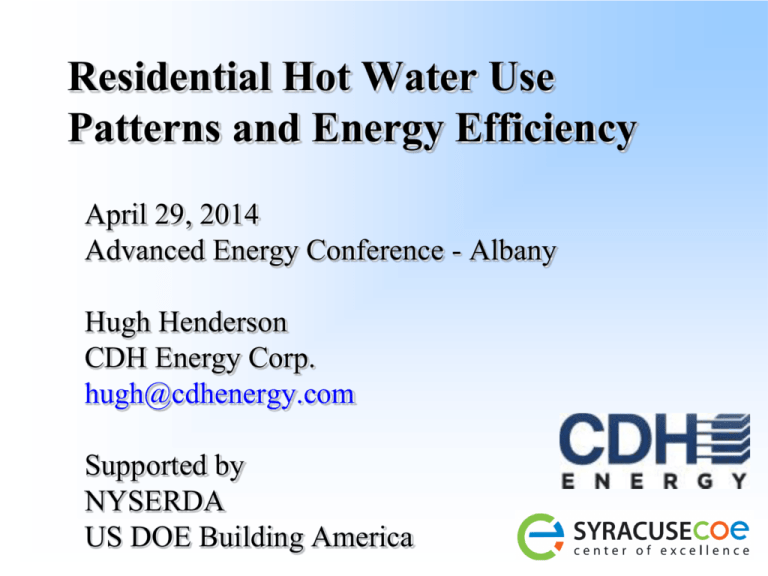

Residential Hot Water Use Patterns and Energy Efficiency April 29, 2014 Advanced Energy Conference - Albany Hugh Henderson CDH Energy Corp. hugh@cdhenergy.com Supported by NYSERDA US DOE Building America 1 Why does DHW Matter? • Water heating 2nd largest load in NY Homes – Bigger than cooling; approaching magnitude space heating in some highly-efficient homes – New technologies are being developed • Performance differences between wide array of DHW technologies not always clear – Performance/efficiency depends on water use (64 gallons/day may not apply any more) – DOE Test and Rating Procedures to determine EF are currently being revised – Large impact of distribution system performance2 Project Overview • Side-by-Side Laboratory Testing – Impose the same water use pattern on systems and compare performance – Compare solar water heating to other technologies • Field Testing – Confirm actual field-measured performance – Quantify load profiles in actual homes – Understand impact of HW distribution • Technology Transfer – Develop a Guide to help consumers 3 Laboratory Testing Standard Gas Water Heater (WH) Unit 1 STD GAS (EF=0.58) Unit 2 PWR VNT GAS (EF=0.67) 4 Laboratory Testing – Solar/HPWH Unit 3 SOLAR (SEF=3.2) Unit 4 SOLAR DRAIN Unit 8 HPWH (EF=2.4) 5 Laboratory Testing High Efficiency Gas Unit 5 TANKLESS (EF=0.94) Unit 6 HE COND TANK (TE=0.96) Unit 7 HYBRID (TE=0.90) 6 Lab Instrumentation Gas Storage and Tankless Water Heaters (Units 1, 2, 5, 6, & 7) Cold in Hot out TC TH Flow Limiters (1 & 2 gpm) TFG FW • • Solenoid Valves • • • WE Electric Natural gas Measure Flow, ΔT & Q out Fuel input Control Inlet water temp Flow rate Specify as daily profile (multiple draws: time, flow, duration) FG 7 Imposed Water Use Profile Proposed “Normal Use” pattern 09/19/13 20 Water Use: 65.2 gal/day HW Use (gal) 15 10 5 0 22: 0: 18 19 2: 4: 6: 8: 10: 12: 14: 16: 18: 20: 22: 0: 20 8 Realized Performance in Lab “Normal Profile”, Sep-18 to Oct-31 9 Field Testing Goal • Measure HW daily use profiles (all 18 sites) • Measure inputs, thermal outputs and efficiency as well as component status and operating conditions under actual use patterns (at 3 detailed sites) • HW distribution measurements at 5 sites. Install temperature sensors on distribution piping to: – allocate water draws to key end uses (sinks, showers, dishwashers, etc) – Estimate HW “waste” in distribution piping 10 15-minute Profile – 2 People February 15-Minute Daily Profile for 2-Person Home in February 0.50 Site Site Site Site Site Site Site Site Site Flow (gpm) 0.40 9 Sites Average Daily Total: 42.6 gal/day Daily Range: 0.0 to 110.8 gal/day 1 3 5 9 10 11 13 14 15 0.30 0.20 0.10 0.00 0 2 4 6 8 10 12 14 Hour of Day 16 18 20 22 24 11 A Kitchen Sink Draw Event 12/02/12 09:05:50 GAL = 0.27 0.8 0.6 0.4 0.2 0.0 45. 50. 55. 0. 5. 10. 15.20. 25. 30. 35. :5 :6 140 TC = Cold 30 3 20 10 2 43 2 1 5 1 8 7 6 5 4 0 -10 45. 50. 55. 0. 5. 10. 15.20. 25. 30. 35. :5 12/02/12 09:05:50 Intervals=10 Temperature (F) TH - Hot Temperature Rise (F) Flow Rate (gpm) 1.0 :6 TT3: Trunk Temp 3 - Kitchen Trunk: Rise= 21.6 TT4: Trunk Temp 4 - Half Bath Trunk: Rise= 0.2 120 1 100 3 2 6 80 4 2 3 8 5 1 57 4 60 40 45. 50. 55. 0. 5. 10. 15.20. 25. 30. 35. :5 Kitchen Sink Useful GAL = 0.00 (TF > 90. ) TF2: Fixture Temp 2 - Kitchen Sink: Rise= 5.5 TF3: Fixture Temp 3 - Sink (half bath): Rise= 0.4 :6 DHW Site 1 12 Classification Success Rate Site 1 Dishwasher Kitchen Sink Halfbath Sink Washing Mach Utility Sink Master Sink Master Shower Bath2 Sink Bath2 Shower Unaccounted All Events Classified % Classified No of Days: Events Total HW per Use day (gpd) 1.5 17.0 2.1 0.7 0.3 6.8 1.5 1.7 0.7 36.8 69.4 33 47% 123 2.7 9.1 0.7 9.1 0.9 2.2 17.8 1.2 8.4 3.4 55.4 52.0 94% Useful Wasted HW HW Useful (gpd) (gpd) % 2.4 0.3 5.7 3.3 0.1 0.5 8.3 0.8 0.5 0.4 0.6 1.5 17.0 0.8 0.6 0.6 7.7 0.8 0.0 3.4 42.9 12.5 42.9 9.1 100% 73% No of Events: Useful = T is Over 90°F at Fixture 90% 63% 21% 91% 53% 28% 95% 49% 91% 0% 77% 82% 8534 13 HPWH and Resist Elements DHW1 - 04/10/13 to 12/02/13 3.0 Conversion Efficiency (-) 2.5 2.0 1.5 1.0 Elements ON 0.5 0.0 0 50 100 Hot Water Use (gal/day) 150 200 14 Summary • Conventional systems perform closest Rated EF • High efficiency condensing systems below expectations • Solar systems and HPWH systems strongly dependent on operating conditions • Draw patterns (and specific events) affect performance – For instance, resistance element operation 15