Casting II

advertisement

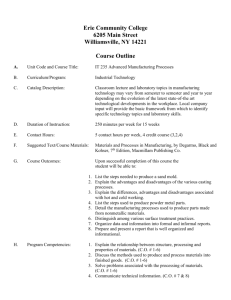

Metal Casting II Manufacturing Processes Outline Sand Casting Shell Mold Casting Composite Molds Expendable Pattern Casting Plaster Mold Casting Ceramic Mold Casting Investment Casting Pressure Casting Vacuum Casting Die Casting Centrifugal Casting Squeeze Casting and Semisolid Metal Forming Casting Single Crystals Rapid Solidification Melting Design Considerations Examples of Cast Parts Examples of Cast Parts Typical Casting Metals Aluminum Aluminum-silicon alloy Aluminum-copper Brass Gray cast iron Copper Lead Steel Casting Processes Sand Casting Uses a mold made of compressed sand; after the metal solidifies, the sand is broken away Sand Casting Pattern Full sized model of the part Core Full sized model of the interior surfaces of the part Sand Silica (SiO2) 90% sand 3% water 7% clay Sand Casting Sand Casting Example of a Sand Casting Mold Sand Casting Advantages: Almost no limit on size, shape, weight or complexity; low cost; almost any metal Limitations: Relatively poor tolerances and surface finish; machining often required; low production rate Common metals: Cast irons, steel, stainless steel, casting alloys of aluminum and copper, magnesium and nickel Sand Casting Size limits: 1 oz – 6000 lb Thickness limits: As thin as 3/32 in, no maximum Tolerances: 1/32 in for the first 6 in, .003 in for each additional inch; additional increment across the parting line Draft allowance: 1 - 3° Surface finish: 100 -1000 µin Shell Casting Casting process in which the mold is a thin shell (typically 3/8 inch) made of sand held together by a thermosetting binder Shell Casting Shell Casting Advantages: Higher production rate than sand casting; high dimensional accuracy and smooth finish Limitations: Requires expensive metal patterns; resin adds to cost; part size is limited Common metals: Cast irons, casting alloys of aluminum and copper Shell Casting Size limits: 1 oz minimum; usually less than 25 lb; mold area usually less than 500 in2 Thickness limits: 1/16 – ¼ in depending on material Tolerances: .005 in/in Draft allowance: ¼ - ½° Surface finish: 50 – 150 µin Composite Molds Made from 2 or more different materials Good for complex shapes such as turbine blades Expendable Pattern Casting Polystyrene pattern vaporizes on contact with molten metal Foam Pattern of an Engine Block Plaster Mold Casting Uses a mold made of plaster (gypsum) with talc and silica, which is broken away after the metal solidifies The mold has a relatively low thermal conductivity; a somewhat uniform grain structure can be produced Plaster Mold Casting Advantages: High dimensional accuracy and smooth finish; can make net- or near-net-shaped parts Limitations: Lower temperature nonferrous metals only; long molding time; mold material is not reusable; maximum size limited Common metals: Primarily aluminum and copper Plaster Mold Casting Size limits: 1 oz – 15 lb Thickness limits: As thin as .025 in Tolerances: .005 in on the first 2 in; .002 in per additional inch Draft allowance: ½ - 1° Surface finish: 50-125 µin Ceramic Mold Casting Uses a mold made of refractory ceramic materials which can be used for high-temperature applications Ceramic Mold Casting Ceramic Mold Casting Advantages: Intricate detail, close tolerances, smooth finish Limitations: Mold material is expensive and not reusable Common metals: Ferrous and high-temperature nonferrous metals are most common; can be used with alloys of aluminum, copper, magnesium, titanium and zinc Ceramic Mold Casting Size limits: Several ounces to several tons Thickness limits: As thin as .05 in, no maximum Tolerances: .005 in on the first inch; .003 in per additional inch Draft allowance: 1° Surface finish: 75-150 µin Investment Casting Uses a wax pattern which is coated with refractory materials to form a mold; the wax is then melted out and the mold cavity is filled with metal Can be used for high precision complex shapes from high melting point metals that are not readily machinable Investment Casting Example of a Wax Injection Mold Example of a Wax Pattern Example of a Coated Pattern Example of Finished Castings Investment Casting Advantages: Excellent surface finish; high dimensional accuracy; nearly unlimited intricacy; almost any metal; no flash or parting line Limitations: Expensive patterns and molds; high labor costs; limited size Common metals: Mainly aluminum, copper and steel; also used with stainless steel, nickel, magnesium and precious metals Investment Casting Size limits: As small as 1/10 oz; usually less than 10 lb Thickness limits: As thin as .025 in, less than 3 in Tolerances: .005 in on the first inch; .002 in per additional inch Draft allowance: none required Surface finish: 50-125 µin Pressure Casting Pressure casting forces the metal up into the mold chamber by applying a small amount of pressure Vacuum Casting Permanent Mold Casting (Pressure/Vacuum) Advantages: Good surface finish and dimensional accuracy; metal mold causes rapid cooling and fine grain structure; molds can be used up to 25 000 times Limitations: High initial mold cost; shape, size and complexity are limited; mold life is very limited with metals with high melting points Common metals: Alloys of aluminum, magnesium and copper most common; iron and steel can be used in graphite molds; alloys of lead, tin and zinc also used Permanent Mold Casting (Pressure/Vacuum) Size limits: Several ounces to about 150 lb Thickness limits: Minimum depends on material but generally thicker than 1/8 in; maximum about 2 in Tolerances: .015 in for the first inch and .002 in for each additional inch; .01 in added across the parting line Draft allowance: 2 - 3° Surface finish: 100 - 250 µin Die Casting Another form of permanent mold casting; molten metal is forced into the mold cavity at pressures ranging from .7 MPa - 700 MPa Die Casting Die Casting Example of a Die Casting Mold Centrifugal Casting Uses a rotating mold to form hollow cylindrical parts such as pipes, gun barrels and lamp posts Vertical Centrifugal Casting Centrifugal Casting Advantages: Can produce a wide range of cylindrical parts; good dimensional accuracy and cleanliness Limitations: Limited shape; spinning equipment may be expensive Common metals: Iron, steel, stainless steel, alloys of aluminum, copper and nickel Centrifugal Casting Size limits: Up to 10 ft in diameter and 50 ft in length Thickness limits: Wall thickness .1 – 5 in Tolerances: Outer diameter within .1 in; inner diameter within about .15 in Draft allowance: 1/8 in / ft Surface finish: 40 - 100 µin Semicentrifugal Casting Uses a rotating mold to form parts with radial symmetry, such as wheels with spokes Squeeze Casting A combination of casting and forging; a die applies pressure as the metal solidifies Casting Single Crystals Uses a slow crystal-growth solidification procedure to produce parts made of a single crystal with no grain boundaries A helical constriction only allows one crystal of favorable orientation to grow into and fill the mold chamber Casting Single Crystals Rapid Solidification Cools metal rapidly at rates as high as 106 K/s so that it cannot crystallize and instead forms an amorphous glasslike structure Melting Furnaces Cupola Crucible Furnace Induction Furnace Melting Furnaces Cupola A vertical cylindrical furnace used for melting cast iron Melting Furnaces Crucible furnace Melts metal without direct contact with a burning fuel mixture Melting Furnaces Induction furnace Uses an alternating magnetic field to heat the metal Design Considerations Design Considerations Design Considerations Design Considerations Casting Alloys Summary A variety of casting processes are available for different applications Design considerations must be taken to prevent casting defects