IT235 - SharePoint - Erie Community College

advertisement

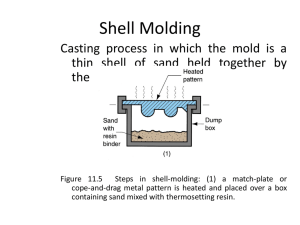

Erie Community College 6205 Main Street Williamsville, NY 14221 Course Outline A. Unit Code and Course Title: IT 235 Advanced Manufacturing Processes B. Curriculum/Program: Industrial Technology C. Catalog Description: Classroom lecture and laboratory topics in manufacturing technology may vary from semester to semester and year to year depending on the evolution of the latest state-of-the art technological developments in the workplace. Local company input will provide the basic framework from which to identify specific technology topics and laboratory skills. D. Duration of Instruction: 250 minutes per week for 15 weeks E. Contact Hours: 5 contact hours per week, 4 credit course (3,2,4) F. Suggested Text/Course Materials: Materials and Processes in Manufacturing, by Degarmo, Black and Kohser, 7th Edition, Macmillam Publishing Co. G. Course Outcomes: Upon successful completion of this course the student will be able to: 1. List the steps needed to produce a sand mold. 2. Explain the advantages and disadvantages of the various casting processes. 3. Explain the differences, advantages and disadvantages associated with hot and cold working. 4. List the steps used to produce powder metal parts. 5. Detail the manufacturing processes used to produce parts made from nonmetallic materials. 6. Distinguish among various surface treatment practices. 7. Organize data and information into formal and informal reports. 8. Prepare and present a report that is well organized and informational. H. Program Competencies: 1. Explain the relationship between structure, processing and properties of materials. (C.O. # 1-6) 2. Discuss the methods used to produce and process materials into finished goods. (C.O. # 1-6) 3. Solve problems associated with the processing of materials. (C.O. # 1-6) 4. Communicate technical information. (C.O. # 7 & 8) Advanced Manufacturing Processes Page 2 I. SUNY General Education Knowledge Areas: Not applicable J. ECC Graduate Learning Outcomes (GLO) K. Assessment of Student Learning: Achievement of the course outcomes will be measured by 3 hourly exams, final exam, formal and informal laboratory reports as well as the oral presentation. L. Library Resources: Machinery’s Handbook-27th Edition, Industrial Press, 2004 Library Internet M. Topical Outline: I Introduction 1. Communicate effectively. (C.O. # 2, 3 & 8) 2. Read and think critically. (C.O. # 1-8) 3. Apply appropriate mathematical procedures and quantitative methods. (C.O. # 7 & 8) 9. Demonstrate adequate preparation for a career or continuing education. (C.O. # 1-8) 10. Demonstrate competence with computers and technology. (C.O. # 7 & 8) 1 period II Fundamentals of Casting Review A. Terminology B. Solidification C. Cast Structure D. Molten Metal Problems E. Fluidity F. Risers G. Patterns H. Cores 3 periods III Sand Casting A. Patterns B. Sand Conditioning/Control C. Sand Properties D. Sand-Related Defects E. Making Sand Molds F. Types of Sand Molds 9 periods IV Other Casting Processes A. Rubber-Mold Casting B. Investment Casting C. Full-Mold or Lost-Foam Process 9 periods D. Permanent Mold Casting E. Die Casting Advanced Manufacturing Processes Page 3 Topical Outline Continued F. G. Centrifugal Casting Continuous Casting V Powder Metallurgy A. Powder Manufacture B. Powder Mixing and Blending C. Compacting D. Dies E. Injection Molding F. Sintering G. Presintering H. Hot Isostatic Pressing I. Secondary Operations 3 periods VI Hot Working A. Basic Rolling B. Forging C. Extrusion 2 periods VII Cold Working A. Rolling B. Extrusion C. Bending D. Piercing/Blanking E. Drawing 3 periods VIII Fabrication of Plastics A. Casting B. Blow Molding C. Compression Molding D. Injection Molding E. Vacuum Forming 3 periods IX Processing of Ceramics A. Glasses B. Crystalline Ceramics C. Firing 3 periods X Fabrication of Composites A. Particulate Composites B. Laminar Composites C. Fiber-reinforced Composites D. Pultrusion 3 periods E. Filament Winding F. Lamination Advanced Manufacturing Processes Page 4 Topical Outline Continued G. H. I. N: Injection Molding Braiding Metal-Matrix Composites XI Surface Treatments A. Hot dip galvanizing B. Anodizing C. Electroless Nickel Plating D. Vacuum Coating 3 periods XII Examinations 3 periods XIII Laboratory Outline A Introduction: Report writing, laboratory safety B. Sand Mold Production, Melting of Aluminum C. Lost Foam Process D. Investment Casting E. Rubber Molds F. Permanent Mold Casting G. Cold Rolling/Recrystallization H. Senior Research Topic 1 period 3 periods 2 periods 2 periods 1 period 1 period 2 periods 3 periods Prepared by: Mary Jane Hornung