Illinois Institute of Technology

advertisement

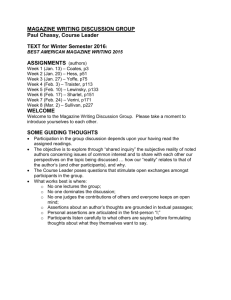

LH2 Absorber R & D Illinois Consortium for Accelerator Research (IIT, NIU, UC, UIUC), U Miss Oxford U Mary Anne Cummings NIU Feb. 9, 2002 Mucool FNAL Mucool LH2 Absorber Collaboration E. L. Black, M. Boghosian, K. Cassel D. M. Kaplan, W. Luebke, Y. Torun Illinois Institute of Technology S. Ishimoto, K. Yoshimura KEK M. A. Cummings, A. Dyshkant, D. Hedin, D. Kubik Northern Illinois University D. Errede, M. Haney University of Illinois, Urbana-Champaign M. Reep, D. Summers University of Mississippi Y. Kuno Osaka University G. Barr, W. Lau Oxford University C. Darve, C. Johnstone*, A. Klebaner, B. Norris, M. Popovic, S. Geer FNAL * also research faculty at IIT Feb. 9, 2002 Mucool FNAL Absorber Window Design Modified Torispherical integrated window and flange design (tapered detail at left). Machine parameters shown. r r R Precision measurement of window and flange with CMM at FNAL Industrial Center. Feb. 9, 2002 Mucool FNAL Window manufacture (U of Miss) Flange/window unit machined from aluminum piece Backplane for window pressure tests Feb. 9, 2002 Mucool FNAL Window Test Setup Test setup at NIU for window , front view: pressure control system Backplane with connections, and with window attached Strain gages applied to window Feb. 9, 2002 Mucool FNAL Photogrammetry FEA calc. for displacement • Non-contact measurement of strain by calculating displacement • Compare with strain gage readout and FEA calculations Feb. 9, 2002 Mucool FNAL Photogrammetry measurements during earlier pressure test. Note the projected dots! Feb. 9, 2002 Mucool FNAL Latest window burst test Feb. 9, 2002 Mucool FNAL 1. Rupture tests 130 m window The Latest: 340 m window 3. Leaking appeared at 31 psi ..outright rupture at 44 psi! 2. 350 m window Burst at ~ 120 psi Feb. 9, 2002 Mucool FNAL Burst at > 120 psi Comparison of results on 130m window 1 at 0.18 Mpa test pressure: FEA, elastic region only Deformation of Window end-cap Vs test pressure 0.6 FEA, non-elastic region included Test pressure (MPa) 0.5 0.4 0.3 P=.18MPa 0.2 0.1 0 0 40 60 80 100 120 distance from end-cap centre line (mm) NIU Photogrammetry results & non-linear FEA calculation Feb. 9, 2002 20 FEA results by Oxford Mucool FNAL 140 160 Comparison of results on 130m window at 0.24 Mpa test pressure Comparing the Oxford and linear FEA results with the NIU photogrammetry data Deformation of Window end-cap Vs test pressure 0.8 Test pressure (MPa) 0.7 0.6 0.5 0.4 P=.24PMa 0.3 0.2 0.1 0 0 20 40 60 80 100 120 distance from end-cap centre line (mm) FEA, non-elastic region included Feb. 9, 2002 Mucool FNAL 140 160 FEA Calculations • 350 micron window (W. Lau) • Non-elastic region included • Three dimensional analysis, necessary for vibrational analysis Stress distribution when first yield developed at 77.7psi (0.536 MPa) pressure Feb. 9, 2002 Mucool FNAL Flow Tests Density maintenance: 1. Nozzle design and arrangement (E.Black, S. Dyshkant) Bates LH2 target heat carrying performance determined by total eN cross section measurements. We’ll need other confirmation. 2. 3-dim LH2 absorber flow simulations (W. Lau) Will run 3-d sims for water, air, LH2 – demonstrate for water with the “analog” simulation at NIU 3. Absorber instrumentation Absorber integrated into a cryo system, with extreme temperature and pressure variations considered for safety. Heat loss/feedthrough Feb. 9, 2002 Mucool FNAL Results of the fluid flow analysis:Oblique nozzle arrangement with air flow at room temperature Air inlet Inlet velocity = 100 m/s Velocity profile in Y-direction Feb. 9, 2002 Mucool FNAL Safety Mu-Cool Safety Panel has been formed. It consists of: Wes Smart (Chairman) Jim Kilmer Jim Priest Safety guidelines 1. Results of FEA calculations which show that the maximum window stress at 25 psid 2. 3. 4. 5. internal pressure is less than (0.25)x(ultimate strength). Results of a cold pressure test per paragraph II.C.3.b.(i) (for metal flasks) of the LH2 Target Guidelines. I would suggest that at least one window be burst under cold conditions. Burst test at NIU with nitrogen Results of a room temperature pressure test per paragraph II.C.3.b.(ii) of the LH2 Target Guidelines. Burst test Copy of the Material Certification Sheet of the material from which the windows are fabricated provided Other; including results of tensile testing samples of the material. Feb. 9, 2002 Mucool FNAL Design of LINAC LH2 Absorber Beam Test Feb. 9, 2002 Mucool FNAL Next Burst test with nitrogen at NIU 1st safety report to committee Flow tests/ 3-d FEA study Heat exchange/containment for LH2 cryostat Instrumentation Feb ‘02 Mar ‘02 Apr ’02 May ‘02 Jun ’02 - ?? LH2 safety LH2 monitoring LH2 physics 11 cm radius absorber Data acquisition Jun ’02 - LH2 Beam Cryotests for convection at NIU Jul ’02 - ?? The program gets redefined after every milestone! Feb. 9, 2002 Mucool FNAL Thin Window Design Minimize window thickness: Minimum thickness depends on shape (ASME Standard) Hemispherical: t = 0.5PL / (SE - 0.1P) s = 0.5D Ellipsoidal: t = 0.5PD / ( SE - 0.1P) s = .25D Torispherical: t = 0.885PD / ( SE - 0.1P) s = .169D t = min. thickness s = sagitta Feb. 9, 2002 s Variable thickness near window edges can further reduce the minimum window thickness near beam: r Title: Title: Creator: Creator: Previe w : This EPS picture w as not saved w ith a preview inclu ded in it. Comment: This EPS picture w ill prin t to a PostScrip t prin ter, but not to other types of prin ters. Previe w : This EPS picture w as not saved w ith a preview inclu ded in it. Comment: This EPS picture w ill prin t to a PostScrip t prin ter, but not to other types of prin ters. D R r displacement displacement r L R r Mucool FNAL beam axis beam axis ANSYS Finite Element Analysis, Zhizing Tang, FNAL. Strain Gage Measurement • Measure the strain on window with strain gages • Use Finite Element Analysis program (ANSYS) to relate vessel pressure to maximum window strain – confirm this with strain gages applied to window surface FEA mesh for calcs. on the window-flange unit < two different gages Instrumented window Feb. 9, 2002 Mucool FNAL Strain gage data 350m window Strain vs. time – the gage ceases to return to resting position after ~ 80 psi; demonstrating point. Strain vs time -the can seeyield that rosette did not return to 0 ustrain after experiencing ~80psi 2000 1.20E+02 Uniaxial at 132mm Rosette at 12 mm Left gage. Pressure 1.00E+02 Rosette Gage at 12 mm yielding.. Rosette at 12mm showing yielding.. 1500 5000 8.00E+01 4500 1000 4000 PSI Microstrain 6.00E+01 3500 4.00E+01 3000 2.00E+01 microstrain 500 2500 2000 0 0 500 1000 1500 2000 2500 0.00E+00 1500 1000 -500 -2.00E+01 500 Time (s) -20.00 0 0.00 20.00 40.00 60.00 -500 PSI Feb. 9, 2002 Mucool FNAL 80.00 100.00 120.00 Forced-Flow Absorber Design External Heat Exchange: Mucool ~ 100W (E. Black, IIT) Large and variable beam width => large scale turbulence Establish transverse turbulent flow with nozzles – complicated, hard to simulate Feb. 9, 2002 Mucool FNAL Convection absorber design Convection cell is driven by heater and particle beam. Heat exchange via helium tubes near absorber wall. Internal heat exchange: Flow is intrinsically transverse. Output from 2-dim Computational Fluid Dynamics (CFD) calcs. illustrate the concept. (K. Cassel, IIT) < Lines indicate greatest flow near beam center. Studies are encouraging, but there is a poorly known parameter: hLH2, coefficient of convective heat transfer. Prototyping of this design is being done by Shigeru Ishimoto et al at KEK. Feb. 9, 2002 Mucool FNAL