Supply Chains: definition and tactical objectives

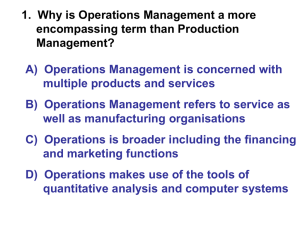

advertisement

SUPPLY CHAIN DEFINITION AND TACTICAL OBJECTIVES Jean-Marie PROTH INTRODUCTION • • • • Only recently has the pressure of the competitive market and new information technologies affected the structures of the production systems, calling for: Reduction of time to market. Higher flexibility of the systems. Drastic reduction of costs. Extended quality concept. DEFINITION OF A SUPPLY CHAIN • A Supply Chain is a global network of organizations that cooperate to improve the flows of material and information between suppliers and customers at the lowest cost and the highest speed. • The objective of a Supply Chain is customer satisfaction. Thus, the goal is not only to meet the tolerances defined by the designer. SUPPLY CHAINS Remarks: - Viewed from the outside, a Supply Chain is a unique entity with, in particular, a unique strategy. - Companies involved in a Supply Chain could be companies that compete to perform the same activities. This requires an agreement between participants (sharing process) at the strategic level. SUPPLY CHAIN AT THE TACTICAL LEVEL This part of the presentation focuses on the partial objectives to be reached in order to fulfill customers’ satisfaction. A financial and operational evaluation are proposed as a conclusion. INTRODUCTION A decision made by any partner of the Supply Chain disseminates among the whole Supply Chain. It means that such a decision requires adjustment decisions from the other partners. As a consequence, a global information system is necessary to allow all the partners to be informed in real time of the state of the system and the decisions made anywhere in the system. Also, each partner should accept the rules derived from the co-operation arrangements decided at the strategic level. The goal of these rules is to make sure that each one of the partners is prepared to adjust itself to any decision that complies with these rules. The sharing process is one of the most important rules THE TACTICAL OBJECTIVES IN A SUPPLY CHAIN The global objective of a Supply Chain is customers’ satisfaction. At the same time, individual components of the Supply Chain aim at maximizing their shareholder value by maximizing the Return on Investment (ROI) of their investors. ROI is the ratio of profit to capital employed over one year. This strategic objective can be translated into several short- and medium-term objectives at the tactical level. The main tactical level objectives in a Supply Chain are: • Minimizing the time required for converting orders into cash. • Minimizing the total Work-In-Process (WIP) in the Supply Chain. • Improving pipeline visibility, that is the visibility of each one of the activities of the Supply Chain by each one of the partners. • Improving visibility of demand by each one of the partners. • Improving quality. • Reducing costs. • Improving services. Minimizing the time required converting orders into cash This objective is much more than reducing the production cycle. It includes the time required to get raw material and components, to control their quality, to handle and, if necessary, store them until they are used. It also includes the time finished products are stored and prepared to be shipped to retailers, the transportation time, and the time they are stored again before being delivered to customers. Minimizing the time required to convert orders into cash requires scheduling each order as soon as it arrives in the Supply Chain. This scheduling activity should cover simultaneously all the activities, that is buying, making, moving, storing and selling activities. Due to the complexity of the scheduling problems and the fact that each order is scheduled as soon as it arrives in the Supply Chain, re-scheduling of existing tasks should be avoided, baring exceptional cases. • The times needed to perform the activities required to complete a process can be reduced gradually through the mapping of the project process and the analysis of each one of the activities. • Reengineering is an abrupt approach that is hard to apply. Mapping of the project process Time t6 t5 t4 t3 t2 t1 a1 a2 a3 a4 a5 a6 Activities Minimizing the total Work-In-Process (WIP) • In the past, the relationships between the partners of the production chains were more adversarial than cooperative. Each one of them was trying to increase its own efficiency instead of working to increase the global efficiency of the system. The goal of each partner was not to decrease inventories, since inventories favor productivity, but more to move them upstream or downstream in the chain to keep the advantages of inventories while transferring the related costs to other partners or subcontractors. This was quite common in the auto industry where auto makers used to ask subcontractors to deliver parts or subsystems "Just-In-Time", which often resulted in transferring inventories to subcontractors. It is still the case in production systems working on a master-slave basis: the "master" builds his success at the expense of the "slaves". The philosophy behind the Supply Chain paradigm is totally different : the goal is to improve the efficiency of the whole system, and thus to reduce the total WIP. A real time approach as been proposed that both minimizes the completion time and control the W.I.P. Improving pipeline visibility The evolution of the computer systems from central mainframe to local workstations has drastically changed the way information is delivered. Nowadays, information can be sent from the place it is generated to any other place in the Supply Chain in real time. Theoretically, this allows close monitoring over product movements, inventories, market changes, logistics, etc. Technical barriers in information systems have been virtually removed. However, two problems remain sensitive when a new Supply Chain is designed. These are: • The removal of the psychological barriers that incite people and organizations to hold back information. • The selection of information to be sent to each partner, including the instants these pieces of information should be sent and their format, are of utmost importance. Improving visibility of demand The goal when improving the visibility of demand is to move the demand penetration point, that is the point of the Supply Chain where the demand is known, as downstream as possible. Tools are available to know with a reasonable probability the customers’ demands even before it emerge in their brains. Improving quality • Quality is often defined as "the set of properties and characteristics of a product or a service that allows it to meet requirements that are explicitly or implicitly expressed by the customer”. • Three main aspects should be considered when talking about quality. These are quality mastery, quality insurance and total quality. Quality Mastery Quality mastery involves evaluating the product or service characteristics’ fit with the specifications provided by the designers or the customers. Quality mastery implies the ability to measure quality which, in turn, allows measuring the efficiency of the activities performed to improve quality. Quality Insurance • The goal of quality insurance is to guaranty the required quality level for services and products. Quality insurance is often supported by the ISO (International Standard for Organization). ISO 9004 provides a guide for the management of quality system while ISO 9001, 9002 and 9003 aim at establishing quality standards that guarantee the level and invariability of quality. Total Quality • Total quality requires a special management, called Total Quality Management (TQM), that involves each employee in the organization in the improvement of quality. • Total quality is a never-ending effort to improve quality. It could be gradual (Kaizen) or drastic (reengineering). Reducing costs • For years, the so-called analytical accounting relied upon arbitrary allocation of indirect costs to product types or services, and hence made it impossible to evaluate the true profitability of these product types or services. Accounting techniques have evolved dramatically (and positively) during the past few years, due to the new project-oriented paradigm, which is the most important characteristic of Supply Chains. Two basic rules are taken into account when evaluating the costs in a Supply Chain. These are: • Costs should be attached to projects instead of departments, i.e. the approach when evaluating costs should be horizontal instead of vertical. • Only incremental costs should be considered. These incremental costs should be evaluated for each activity of the project and even for each customer segment. Two approaches are used to reduce the incremental costs of a project. These are: • A gradual approach, similar to the Kaizen approach applied to improve quality. • A more abrupt approach which consists in changing drastically the manufacturing process (reengineering). Improving services • Factors that improve customer service are the reduction of time from customers’ orders to deliveries and the improvement of the quality of product / service documentation, reception of customers and information about the Supply Chain. PERFORMANCE EVALUATION OF A SUPPLY CHAIN Financial evaluation Costs to take into account in the evaluation are the costs per unit (of product, or service). This cost per unit should be compared with the price paid by customers to enjoy the product or the service. • The above evaluation tasks concern the short-term horizon. This is not enough to decide if a product type or service should be a part of the Supply Chain activity. We have to integrate three more parameters in our evaluation, namely: R&D activities, financial resources utilization and cash flow. • R&D activity, which is usually very expensive, is necessary to preserve the competitiveness of the Supply Chain in the long term. It is usually difficult, if not impossible, to assign a part of the R&D cost to a specific type of product or service, except if this R&D activity is dedicated to the project under consideration. • The ROI is sometimes written as follows: ROI=(profit/sales)/(sales/required capital) =margin*capital turnover Written as the product of margin by capital turnover, the ROI is not only more understandable, it can also be easily optimized because profit and sales on one hand, and sales and required capital on the other hand, are handled by the same level of responsibility in the companies. • Another important parameter to consider is the cash flow. Simply speaking, cash flow is the capital available for investments. In some sense, it represents the ability of a Supply Chain to seize new opportunities. Operational evaluation Three main parameters should be measured to evaluate this aspect. These parameters are: - The availability. - The adequacy to customers’ expectations. - Customers’ service Availability • This parameter measures the ability of the Supply Chain to make products or services available to customers faster than competitors. Adequacy to customers’ expectations • The question to be answered here is the following: are the products or services being provided closer to customers’ requirements than those of the competitors? The comparison of the "closeness" of products or services to customer expectation is more difficult to measure. Customers’ service The following measures should be made: • How many phone calls are necessary, on the average, to reach an employee? The result should be as close as possible to one. • How many employees should the customer get in touch with, in order to obtain the information he/she is looking for? The result should also be as close as possible to one. • How long does it take to obtain an appointment? • How long does it take to replace the product in case of breakdown, or to replace the provider of the service if necessary? • What is the average delivery delay? This aspect is important to gain new customers and keep them. As a consequence, this delay should be equal to zero. • What is the percentage of first time satisfied orders, i.e., orders that are correct in quantity and quality? • What is the percentage of invoices that are not accurate? • What is the time required, on average, to complete an incomplete delivery? • What is the time required, on average, to correct an invoice that is not accurate? • Do the Supply Chain offer training if necessary? • Another important factor is a fast and effective reaction to complaints. Flexibility, which is the ability to adapt the outputs of the Supply Chain to the evolution of customers’ requirements, is a major factor for competitiveness