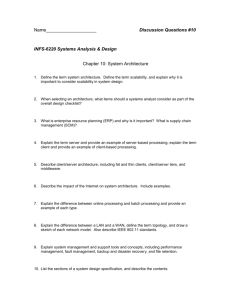

Chapter 13

advertisement

Chapter 13 Order Fulfillment, Logistics, Supply Chain Management 1 Learning Objectives 1. Understand the role of order fulfillment and back-office operations in EC 2. Describe the process of order fulfillment 3. Understand the concept of the supply chain, its importance and management 4. Describe the problems of managing the supply chain and the use of innovative solutions there 5. Describe the need for integrating information systems of front office and back office 6. Trace the evolution of software that support activities along the supply chain and their management 7. Understand the relationship among ERP, SCM and EC. 2 The Y2K Order Fulfillment Problem In Dec. 1999 Competition among E-Tailers increases Special area: Toys; Big promotions, coupons Demand: very high, not anticipated Retailers: were unable to meet demand Customers: very unhappy Similar problems in gifts, book, etc. Also: online retailers has warehousing and logistics problems 3 Order Fulfillment Taking orders may be the easiest part Difficulties in groceries and fresh food One reason: Customized products Second: Pull type manufacturing 4 The Pull vs. Push Model 5 Major Concepts Order fulfillment: Deliver right order on time Front office operations: Order taking, advertisement, CRM Back office operations: Accounting, finance, inventor, packaging, logistics Logistics: Managing the flow of goods, information and money along the supply chain 6 The Process of Order Fulfillment 7 The Steps of Order Fulfillment 1. 2. 3. 4. 5. Payment Clearance In-stock availability Packaging, shipment Insuring Production (planning, execution) 6. Plant services 7. Purchasing, warehousing 8. Demand forecast 9. Accounting, billing 10. Customer contacts 11. Returns (Reverse logistics) 8 Shipping a Tropical Fish 1. Placing order, payment 2. Transfer order to petstore.com, check stock 3. Use an wholesaler to get the fish 4. Supplier finds fish, ships to wholesalers 5. Wholesalers rushes to Petstore 6. Petstore uses FedEx to ship to customer with copy of credit card payment Discussion: What is the contribution of EC? 9 Why Intermediaries? 1. Wholesaler and deliveries in the Petstore case 2. Wholesalers as an aggregators; between many sellers and buyers 3. Can a virtual store replace a retailer? 4. Direct sales for large items 5. Example: The Lego Co. case 10 Channel Conflict Elimination of Intermediary many create a conflict Conflict between online and offline distribution This may impact order fulfillment and returns What if a manufacturer sells both wholesale and retail? (Microsoft) Customized product by manufacturers: ideal 11 for direct sale Supply Chain Management Definition: Flow of material, information, money, etc. from raw material suppliers through factories to customers It includes: organizations, procedures, people SCM: Integration of the business processes along the chain, Planning, Organizing, control of many activities Activities: Purchasing, delivery, packaging, 12 checking, warehousing, etc. Components of the Supply Chain 13 Components-Description Upstream: Suppliers, their suppliers (several tiers). From Raw material to the company Internal: All internal process that add value, conversion to find products Downstream: All activities in distribution and delivery to end customers 14 Complex-nonlinear Supply Chain 15 Benefits of SCM Reduce uncertainty along the chain Proper inventory levels in the chain Minimize delays Eliminate rush (unplanned) activities Provide superb customer service Major contributor of success (ever survival) 16 Global Supply Chain Can be very long Possible cross-broader problems Need information technology support of: communication and collaboration Possible delays due to: customs, tax, translations, politics 17 Problems along the Supply Chain Delays in production, distribution etc. Expensive Inventories Lack of partners’ coordination Uncertainties in deliveries Poor demand forecast Interference with production Poor quality 18 More difficulties Virtual companies do not have logistics infrastructures One company is a member of several supply chain Conventional warehouses are too expensive Need automatic warehouses with robots as pickers 19 Preliminary Activities Understand the supply chain (flow charts) Study internal and external parts Performance measurement are a must (Benchmarking) Multidimension performance analysis a BPR may be needed People’s relationships are a must 20 Areas of Opportunities Manufacturing processes Warehousing operation Packaging and delivery Material inspection/receiving Inbound and outbound transportation Reverse logistics (return) In-plant material handling Vendor management program Customer order processing 21 Areas of Opportunities (cont’d) Invoicing, auditing and other accounting activities Collaboration procedures with partners Employee training and deployments Labor scheduling Use of teams and empowerment of employees Automation of processes Use of software for facilitating all the above Inventory management and control 22 Using Inventories An insurance against stock out Can be in several places Can be excessive Can be insufficient Example: Littlewoods stores; UK 23 Proper SCN Coordination is needed Understanding of the causes/problems Information flow is a key Communication is important IT is needed 24 Information Technology for SCM Links that enable communication/collaboration Links the partners Provide effective and efficient solutions Extremely important Need for information sharing 25 IT as problem solver Supply Chain Problem IT solution Linear sequence of processing – too slow Waiting times between chain segments – excessive Parallel processing, using workflow s/w Existence of non-valued added activities Slow delivery of paper documents Repeat process activities Value analysis (SCM s/w), simulation s/w Identify reason (DSS s/w) and expedite communication and collaboration (Intranets, GroupWare) Electronic documents and communication system (e.g. EDI, email) Electronic verifications (s/w agents), automation; eliminating human errors 26 The bullwhip effect Slight changes in actual demand create problems Partners build “just in case” inventories Lack of trust among partners Stockpilling result in huge cost The manufacturers can not plan production Cannot order material from suppliers 27 Avoiding the sting of the bullwhip Information sharing is a must Trust and agreements How to do it? $30 billion/year just in the grocery industry 28 IT solutions Automate order taking Use EDI/Internet Web based ordering; intelligent agents Electronic payments Make-to-order (JIT) Tracking systems Supplier monitor and manage inventories Information from POS to suppliers Electronic trading markets and exchanges 29 Electronic trading markets/exchanges One company with many suppliers (catalogs, auctions) One company with many buyers (RFQ) Exchanges controlled by few large companies (e.g. ANX) 3rd party managed exchanges Vertical vs. Horizontal portals 30 Non-supply Chain Partnerships Starbucks: Coffee to retailers, customers Needed fast service; less expensive Kozmo delivers in cities 30-60 minutes Kozmo.com: Had a problem with drop boxes for returns Partnership: Place Kozmo’s drop boxes inside starbuck coffee houses (open long hours) solve both problems Amazon uses Kozmo for fast deliveries 31 The Role of 7-Eleven & Convenience Stores Can be used as a collection point for returns Can be used as a pick up place Can be used as a place for order placing Can pay in cash/card to the store Returns are a problem: up to 30% 32 The role of FedEx & Similar Shippers From a delivery to all-logistics Many services (see Box 13.4) Complete inventory control Packaging, warehousing, reordering etc. Tracking services to customers 33 Software Support SCM activities Type of software Upstream activities Suppliers’ management, ordering systems, order tracking systems Internal supply chain - Inventory management activities - Purchasing and order management - Budgeting, cost control - Human resources information Downstream Saleperson productivity tools, activities online telemarketing, ad. Management etc. 34 Integration-Benefits Automation of segments useful, but… Tangible benefits Inventory reduction, personnel reduction, productivity improvement, order management improvement, financial cycle improvements. Intangible benefits Information visibility, new / improved processes, customer responsiveness, standardization, flexibility, globalization, and business performance. 35 Integration along the Supply Chain Need to streamline operations New business models New organizational relationships (virtual companies) Examples Warner Lamber and Wal*Mart (Box 13.5) 36 Areas of Integration Order taking - production inventory levels Payment info in B2B - Visa, Master Card, etc. Low inventory levels - automatic ordering Order to manufacturing - generate a list of needed resources & their availability Changes in an order - transmit to suppliers and their suppliers Tracking systems - available to customers 37 Evolution of Software Integration Completely Independent of each other MRP= Material Requirements Planning: Inventory, production MRPII=Manufacturing Requirements Planning more integrated, MRP+Finance+labor ERP=Enterprise Resources Planning All functional areas Extended ERP=Include suppliers, customers 38 From SAP to mySAP.com SAP=Traditional ERP=Automate and Integrate transactions MySAP.com = web based comprehensive system Workplace - a personalized, role-based interface Marketplace - one stop destination for business professional to collaborate Business Scenarios - products for the Internet and intranet Application-hosing - hosting Web applications for 39 SMEs Enterprise Resource Planning (ERP) ERP = Integrating business processes and activities in real time Solves many supply chain problems Necessary for medium to large corporations Helpful also for some SMEs Need to interface with EC order taking system Manages all routine transactions in the Enterprise Recently extended to suppliers and customers 40 Developing ERP Systems Do it yourself, from scratch (only few will) Use Integrated packages such as R/3 from SAP “Best of Bread” approach, using integrating software Rent in from ASP service 41 Post ERP (2nd Generation) 1st generation - transaction processing orientation 2nd generation including decision making capabilities EC requires decision support EC requires business intelligence SCM software: Production Planning, Manpower utilization, Profitability models, market analysis. Integration of SCM capabilities Other added functionalities: CRM, KM 42 ASP Leasing information systems application Back to the days of “time sharing” A risk prevention strategy Very popular with ERP (expensive, cumbersome) 43