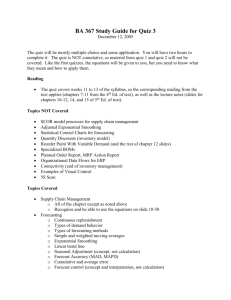

Part 1 - SU4 PP final

advertisement

Part 1 Study Unit 4 Operational Efficiency and Business Process Performance Learning Objectives • You need to be able to answer the following: – Define Just-in-Time systems and describe its central purpose. – Identify and describe the operational benefits of implementing a just-in-time system – Defined the term Kanban and how Kanban is used in a justin-time system – Demonstrate an understanding of how work cells and how they relate to just-in-time processes – Define material requirements planning (MRP) – Identify and describe the benefits of an MRP system – Calculate subunits needed to complete in order for a finished product using MRP Learning Objectives • Calculate subunits needed to complete in order for a finished product using MRP • Explain the concept of outsourcing and identifying the benefits and limitations of choosing this option • Demonstrate a general understanding of the theory of constraints • Identify the five steps involved in a theory of constraints analysis • Define throughput costing (super variable costing) and calculate inventory cost using throughput costing • Define and calculate throughput contribution • Discuss how the theory of constraints activity based costing are complementary analytical tools Learning Objectives • Describe how capacity levels affect product costing, capacity management, pricing decisions, and financial statements. • Explain how using practical capacity as a denominator for fixed cost rate enhances capacity management. • Calculate the financial impact of implementing the above mentioned methods 4.1 Just-In Time Inventory and Lean Operation • Many companies have traditionally built parts and components for subsequent operation on a preset schedule. Such a schedule provides a cushion of inventory so that the next operation will always have parts to work with-they just in case method. • Just-in-time Model (in contrast) – Limits output to the demand of the subsequent operation. – Reduction in inventory • • • • Less money invested in idle assets Less storage space Less inventory taxes Less pilferage – Identify defects in parts due to limited supply – QC is focuses on prevention of quality problems. 4.1 Just-In Time Inventory and Lean Operation • Just-in-time Model Objectives – Higher productivity – Reduced order costs / carrying costs – Faster & cheaper setups – Shorter manufacturing cycle times – Improved quality – Flexible processes – Increased competitiveness and higher profits! 4.1 Just-In Time Inventory and Lean Operation • JIT originated from a Japanese philosophy that combines purchasing, production, and inventory control. It is a reaction to the trends of global competition and rapid technological progress that have resulted in shorter product life-cycles in greater consumer demand for product diversity. • JIT strives to minimize inventory due to many of the inventoryrelated activities do not add value. • Symptom of problems: – Poor quality – Long cycle times – Lack of coordination • JIT is a pull system – Items are pulled through production by current demand, not pushed by anticipated demand. – Examples??? 4.1 Just-In Time Inventory and Lean Operation • JIT allows for the elimination of certain internal controls – Frequent and smaller deliveries requires a less sophisticated inventory control system. – No need for a central warehouse. Delivery made to production centers. – Quality of parts is determined by the use of statistics and not inspection of incoming parts. – Storage, counting, and inspecting are eliminated. Maximize value-added work. 4.1 Just-In Time Inventory and Lean Operation • High inventory levels can often create mass production problems because the effective parts can be overlooked when plenty of good parts are available. If only enough parts are made for the subsequent operation, however, any defects will immediately halt production. • The focus of quality control under JIT shifts from the discovery of defective parts to the prevention of quality problems, so zero machine breakdowns and zero defects are ultimate goals. • Lean operation is often used as a synonym for JIT. 4.1 Just-In Time Inventory and Lean Operation • Therefore JIT suppliers’dependability are crucial. – Use of long-term and negotiated contracts. – Continuous replenishment arrangements. • Reliance on supplier’s forecasting – Use of electronic data interchange (EDI) • EDI allows for the supplier to access the buyer’s online inventory management system. • Frequent receipts of deliveries from suppliers often means less need for sophisticated inventory control system and for control personnel. 4.1 Just-In Time Inventory and Lean Operation • The quality of parts provided by suppliers is verified by the use of statistical controls rather than inspection of incoming goods. Storage, accounting, and inspecting are eliminated an effort to perform only value-adding work. 4.1 Just-In Time Inventory and Lean Operation • JIT and Kanban are often confused. – JIT is a total system. – Kanban is an element within the JIT system. • Kanban = ticket • Tickets control the flow of production or parts so that they are produced or obtained in the needed amounts at the needed times. • Withdrawal kanban – Qty that a later process should withdraw from its predecessor 4.1 Just-In Time Inventory and Lean Operation • Production kanban – States the output of the preceding process • Vendor kanban – Tells a vendor what, how much, where and when to deliver. • US companies have integrated their existing computer systems with the JIT systems. 4.1 Just-In Time Inventory and Lean Operation • Factories are reorganized to permit lean production. • JIT lean production plant layouts arranged by manufacturing cells and not by department. • Workers in each cell must be able to multitask, or may be idle. • Support departments are reduced thereby saving space and allowing for smaller and leaner factories. • Manufacturing cycle time and setup time are also reduced. Flexible! • Team based. Employees are empowered. • Objectives of continuous improvement and zero defects. 4.2 Material Requirements Planning and Outsourcing • Short-range plans must be converted into specific production targets for finished goods. • Raw material deliveries carefully planned. • Master Production Schedule (MPS) • Develops specific dates for completion and availability based on the numbers of finished goods called for in demand forecasts. • Materials Requirements Planning (MRP) • Coordinates both the manufacture of component parts for finished goods and the arrival of raw materials. • Combines production scheduling and inventory control. • Right part, right quantity, right time. 4.2 Material Requirements Planning and Outsourcing • MRP is a Push System • Demand for raw materials is driven by the forecasted demand for the final product. • Computer Program • MRP system utilizes bill of materials (BOM), which and how many subassemblies go into the finished product. 4.2 Material Requirements Planning and Outsourcing • Example on Page 138 4.2 Material Requirements Planning and Outsourcing • MRP creates schedules identifying when inventory items will be needed in the production departments. – Purchase orders are automatically generated based on inventory levels. – Timing of deliveries is vital. • MRP benefits – – – – Reduced idle time Lower setup costs Lower inventory carrying costs Increased flexibility 4.2 Material Requirements Planning and Outsourcing • Manufacturing Resource Planning (MRP II) • Closed-loop manufacturing system that integrates all facets of production, sales, inventories, schedules, and cash flows. – The same system is used for both the financial reporting managing operations (both use the same transactions and numbers). – Because manufacturing resource planning encompasses materials requirements planning, MRP is a component of an MRP II system. 4.2 Material Requirements Planning and Outsourcing • Outsourcing – Management / execution of day-to-day operations by a 3rd party. – Allows focus on core competency and have less concern on marginal activities. • Business Process Outsourcing – Back office and front office functions. • Insourcing – Transfer of an outsourced function to an internal department. • Cosourcing – Internal and external resources. 4.2 Material Requirements Planning and Outsourcing • Outsourcing Advantages – Reliable service – Reduced costs – Technological access – Leverage experts • Outsourcing Disadvantages – Dependence on outsiders – Loss of control – Costs 4.2 Material Requirements Planning and Outsourcing • Outsourcing Advantages – Reliable service – Reduced costs – Technological access – Leverage experts • Outsourcing Disadvantages – Dependence on outsiders – Loss of control – Costs 4.3 Theory of Constraints and Throughput Costing The theory of constraints developed in 1948, as a system to improve human thinking about problems. It has been greatly extended to include manufacturing operations. The basic premise of TOC as applied to the business is that improving any process is best done not by trying to maximize efficiency in every part of the process, but by focusing on the slowest part of the process, call the constraint. 1. 2. 3. 4. Identify the Constraint. Bottleneck operation is where the work-in-process backs up the most. Determine which phase has slack time – phase w/o enough resources to keep up with input. Determine most Profitable Product mix given the constraint. Max contribution margin through the constraint – Throughput margin. Throughput costing (aka Supervariable costing) uses only direct materials costs. Throughput margin = Sales – Direct Materials Maximize the flow through the constraint. Increase capacity at the constraint. Redesign the manufacturing process for greater flexibility and speed. 4.3 Theory of Constraints and Throughput Costing • See Example on p. 140 – 141 • Most profitable use of bottleneck operation – calculate throughput margin per unit of time spent in the constraint. – Profit maximized when bottleneck is busy with the product that has the highest throughput margin per unit of time. 4.3 Theory of Constraints and Throughput Costing Increase Capacity at the Constraint • While making the best use of the bottleneck is encouraged in the short-run, the next best step would be to increase the bottleneck’s capacity. Redesign the Process • Gain greater flexibility and speed. • Long-term solution is to redesign the process • Value engineering – balances product cost and the needs of potential customers 4.3 Theory of Constraints and Throughput Costing Extended Example p. 142 • TOC Analysis complements activity-based costing – focus on different aspects of improvement process – TOC is short-term – ABC is long-term Questions? Intermission • Next - SU 4.4 – 4.6 By Jim Clemons 4.4 Capacity Planning • Strategic planning that is closely related to capital budgeting. • IMA Statement on Management Account Measuring the Cost of Capacity state that: • Maximizing the value created within an organization starts with understanding the nature of capabilities of all the company’s resources. 4.4 Capacity Planning • Strategic planning that is closely related to capital budgeting. • IMA Statement on Management Account Measuring the Cost of Capacity state that: • Maximizing the value created within an organization starts with understanding the nature of capabilities of all the company’s resources. Effective capacity cost management requirements: • Short run – optimize capital investments – ROIC, IRR and NPV analysis • Maximize the value delivered to customers – Value chain analysis • Minimize requirements for future investments • Match firm’s resources with current and future market opportunities. – Utilization rates – redeploy assets • Eliminate waste – • Must provide useful costing information on current process costs (current state) versus the proposed future costs (future state) of an investment. • Capacity usage measurements – Key performance indicators. • Identify capacity requirements to meet strategic and operational objectives. • Detail opportunity cost. • Provide pre-decision information and analysis on the project and the cost of the project. • Create a common language and understanding of capacity cost management. • This is the heart of Lean/Six Sigma. Capacity planning and capital budgeting • Planning capacity levels allows for informed decisions on expansion or disposal. • Capacity costs drive product cost and price. • According to Michael E. Porter: – The decision to expand capacity is a major strategic decision. – Key forecasting problems are long-term demand and the behavior of competitors. • Capacity expansion is also referred to as market penetration. • If your product is profitable, under-capacity is a short term problem. Investors will provide funds or competition enter the market. • Overcapacity is a problem. Price wars drive down margins. Capacity is hard to reverse. • Porter’s model for expansion: – 1) Identify your options, 2) Forecast demand, 3) Analyze the competition, 4) Predict total industry capacity and company share (Share of Wallet) and 5) Test for inconsistencies. Value Chain Analysis To remain on the market, a product must provide value to the customer and a profit to the seller. Customers assign value to a product. Producers can affect the customer’s perception of value Differentiation & lowering price Value Price Costs Consumer surplus Profit margin All costs The Value Chain • It is a model for depicting the way in which every function in a company adds value to a final product. • IMA’s statement on the value chain – “The value chain approach for assessing competitive advantage is an integral part of the strategic planning process.” • The value chain is the firms overall valuecreating process. • Primary activities deal with the product. – R&D, manufacturing, shipping…. • Support activities aid primary activities. – HR, IT, inventory management, accounting Value Chain Analysis The Supply Chain Supply Chain • Is the flow of materials and services from their original sources to final customers. • Involves more than one firm. • To improve performance and reduce cost you must analyze every step of the supply chain. – insourcing versus outsourcing – Vendors must be business partners • Sharing information reduces inventory at every step of the supply chain. Value Engineering • A systematic approach to assessing all aspects of the value chain costs for a product in order to target a specific cost for the product. • Emphasizes controlling costs in design phase • Cost incurrence is the use of resources • Locked-in costs (designed in costs) • Life-cycle costing – highlight upstream and downstream costs that are often overlooked. • Minimize costs without sacrificing customer satisfaction. Process Analysis • Links internal processes to overall strategy • Many types of processes • Continuous, batch, Hybrid, Make-to-stock, Maketo –order. • Degree of interdependence – “tightness” • Tight process – JIT Loose process – Large WIP • The process bottleneck is the slowest part of the process. Only an issue when plant is at full capacity. Process Value Analysis • Is the comprehensive understanding of how an organization creates its product. • Looks at the value adding and non-value adding steps and looks for ways to reduce or eliminate the non-value adding activities. • ABM links product cost and continuous process improvement to increase stockholder’ value. • Kaizen is a Japanese word for continuous pursuit of improvement in every aspect of operations. • Activity analysis - Eliminate waste add value. Business Process Reengineering (BPR) • Is a complete rethinking of how business functions are performed to provide value to customers. – Radical innovations not continuous improvements. – Current process and people are disregarded. – Employees must be fully engaged in new process. – Emphasis on monitoring internal controls. – Monitoring may be separate, periodic or ongoing. Benchmarking • Is a means of helping companies with productivity management and business process reengineering. • Best-in-class comparison • The key is to build quantitative and qualitative measurements and compare them to other companies that are considered to be the best. • The differences are compared at the root cause and key action level and changes are made. Steps of Benchmarking • Select and prioritize projects – Identify key processes and drivers – How does it relate to the company’s mission, values and strategy. – End goal – Customer satisfaction • Select team – C suite champion – Must have executive buy in. – Cross functional team – Team members must have knowledge of processes Steps of Benchmarking • Investigate and document internal process. – Walk the process – Understand process taxonomy (Arrangement method) • Research and identify best-in-class performance – Set up a database – Choosing information sources – Selecting partners • Data analysis – understand the gaps • Implementation – Leadership is key. Balanced Scorecard • A goal congruence tool to review performance and ensure all objectives are being met. • Typical Measurements – – – – Financial Customer Learning, growth, and innovation Internal business process • May be financial / non financial, internal / external and short term / long term • Best practice tie in Cost of Quality • Conformance costs – Prevention • Attempts to avoid defective output. • PM, employee training, review of equipment design, supplier evaluations – Appraisal • Statistical quality control programs • Inspection • Testing • Nonconformance costs – Internal failure • Costs are detected before shipment • Scrap, rework, tooling changes, downtime, redesign, lost output, re-inspection, retesting, expediting of operations after delays, lost learning opportunities, and searching for and correcting problems. – External failure • Costs are detected after shipment • Customer service complaints, rejection, return, repair or recalls, warranty obligations, products liability claims, loss of customers. – Environmental costs – fines from regulators, lawyer fees, loss of customer goodwill – ISO 14000 Environmental auditing and performance evaluations.