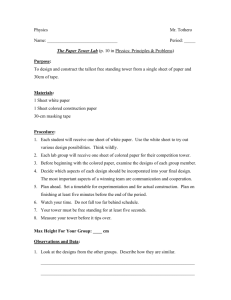

Customer Meeting Presentation 11/7/13

advertisement

P14651: Drop Tower for Microgravity Simulation Adam Hertzlin Dustin Bordonaro Jake Gray Santiago Murcia Yoem Clara Project Summary Problem Goals Design & Build Drop Tower Vacuum Piping Structure Cost Effective Effective Cycle Time Aesthetically Pleasing Precision in Measurements Educational User Interface Access for Object Transfer Adaptability for Future Development Constraints Location and design approval from the dean(s) Material availability/size (ex. tube, pump) The device is aesthetically pleasing The tower 6” – 12” Diameter The device can be operated year round. The system is safe to operate. The project budget is $3,000. Team must justify the need for additional funds. The project must be completed in 2 semesters. Project Deliverables Installed drop tower Detailed design drawings and assembly manual Bill of materials User’s Guide for operation Designed Lab Experiments Determine gravity in the vacuum within 1% error Compare drag at different pressures and drag vs. acceleration Additional vacuum related experiments Fun and Educational Experience for Middle School Students Technical Paper Poster Agenda Customer Meeting Updates Customer Requirements Engineering Requirements Proposed Concept Design Isolation Valve Cost Analysis List of experiments Concept and Architecture Development System Block Sub-systems Summary Risk Assessment Test Plan Bill of Materials Customer Meeting Notes Account for Pipe Fitting Leaks in calculations How does Ultimate Pressure change with Leak Rate? Limit design to one tower Simple Prototype Fit two objects in one tower Allow for lift mechanism Design Concepts to Future Tower Development Go with 6-8 in. Diameter, approx. 10-15 ft. Tall Tower Measure new location heights Dr. K Lab Talk with Mark Smith about using MSD space Does Ultimate Pressure Effect object drop times Feather vs. Ball Bearing Use only one laser when dropping items to measure gravity Keep the educational aspect in mind Customer Requirements Customer Importance Rqmt. # CR1 CR2 CR3 CR4 CR5 CR6 CR7 CR8 CR9 CR10 CR11 CR12 CR13 CR14 CR15 CR16 CR17 CR18 9 9 9 9 9 9 9 9 9 9 9 9 3 3 3 3 3 3 Description Appropriate Tower Height Allow for Adjustable Pressure Display Tower Pressure Drop 2 objects simultaneously Drop objects with no horizontal motion Demonstrate standard local gravity within 1% Display important outputs accurately Allow full drop visibility and limit distortion Demonstrate drag vs. pressure Allow objects to be changed out Safe/Intuitive operation Educational and Inspiring Display Tower Temperature Design considers noise and power requirements and limits Components are properly maintained and stored Aesthetically pleasing Generate object lift mechanism concepts for future MSD Allow for further static experiments Engineering Requirements Rqmt. # SR1 SR2 SR3 SR4 SR5 SR6 SR7 SR8 SR9 SR10 SR11 SR12 SR13 SR14 SR15 SR16 SR17 SR18 I 9 9 9 9 9 9 9 9 9 3 3 3 3 3 3 3 3 3 Engr. Requirement (metric) Measure Relative Object Position Measure Relative Object Drop Time Measure Pressure Cycle Run Time Pressure Leak Rate Minimized Aesthetic Structure with Supports No Horizontal Motion Tube Collapse Pressure Timing difference of object release Tower Height Tower Cross - Section (Diameter) Pump Flow Rate Measure Temperature Impact Energy Dissipation Method Air Intake - Tower Pressure Change Rate Minimal Error in Calculations Aesthetic Data Display Platform for Stationary Experiments Unit of Measure Marginal Value Ideal Value ft sec psi min psi / sec Yes / No in FOS millisecond ft in 0-15 0-2 0-14.7 1-10 mins 0-? Yes 0-? 0-5 0-? 10-15 6-8 >Tower Height ft3/min % Error 2-10 0-1 10 0 Joule 0-(mmaxvfinal2/2) (mmaxvfinal2/2) ft3/min % error Yes / No 0-? 0 - 1% Yes ? 0% Yes in (0.50*ID)-(0.99*ID) (0.99*ID) 0 - 14.7 1 min 0 Yes 0 5 0 15 8 Tube Diameter Selection Weighted Pros and Cons of Tower Diameter % Weight Criteria 6" Dia 8" Dia 10" Dia 20% Low Cost 4 3 1 10% Object Size 2 3 4 10% Lift Mechanism Implementation Ease 2 3 4 15% Evacuation Time 4 3 1 10% Component Design (Drop Mechanism) 2 3 3 15% Component Availability 3 2 1 10% Accessability to Objects 2 3 4 5% FOS for Implosion 4 4 3 5% Support Structure 4 4 4 3.05 2.95 2.35 100% Current Selection: 6" Diameter Tube List of Experiments Dropping two objects simultaneously Measure Gravity Measure Drag Balloon Expansion Marshmallow Expansion Sound Insulator Plastic Bottle Compression Note: The following slides will attempt to justify the required tower pressure and size to complete these experiments CONCEPT & ARCHITECTURE DEVELOPMENT Proposed Concept Designs Proposed Base Structure Selected Concept Designs (part 1) Selected Concept Designs (part 2) Continuous Lift Concept #1 Continuous Lift Concept #2 Use pressure to control the up and down movement of a piston. The piston would transport the objects back to the top of the tower post drop. Air Seal Sub-Systems I. Release Mechanism I. Release system Calculations II. Error Propagation I. Ultimate Pressure II. Sensors III. Air Control I. Evacuation time II. Leak Rate Analysis IV. Catching Mechanism I. Energy dissipation Calculations V. Piping system I. Critical external Pressure VI. Structure I. Tower height calculations II. Support Buckling Tower Height Distribution Critical heights Total height drop at Dr. Kandlikar: Height of lab= 11’ 7” = 139” • With a ceiling clearing of 12” • Drop height = 93.5” = 7.791 Ft • Drop time= 0.696 Seconds • With a ceiling clearing of 22” • Drop Height = 83.5” = 0.657Ft • Drop Time = 0.657 Seconds Total height required for a 10 Ft drop height: • H=13.79 Ft Critical Length of pipe lengths L1 and L2 • Assuming a clearing of 12” • Assuming L1= 1 Ft • L2= 7.692 Ft • Assuming L1= 2 Ft • L2= 6.693 Ft Engineering Analysis Release Mechanism Base Specifications Polycarbonate • Diameter = 6.0 in • Thickness = 0.375 in • ρ = 1.22 g/cm3 6.0” 0.375” (0.0441 lb/in3) Hatch Doors • Length = 1.5 in • Width =4.0 in • Thickness = 0.375 in 4.0” 0.375” 1.5” 1.5” Electromagnet Specifications Electrical Specifications • 12 VDC • Operating temperature of -40F to 140F • Holding Force 4.5lbs Physical Specifications • Weight – 0.06lbs • Diameter – 0.75in • Height – 0.62in Other Specifications • Quick Release Mechanism Hinges Specifications Physical Specifications • Height – 3.5in • Width – 1.5in • Depth – 0.21in • Radius – 5/16in (0.3125in) Pin Specifications • Length – 3.5in • Radius – 9/16in (0.5625in) FBD Important Result Maximum object weight before magnets will disengage prematurely 5.6 lbs Does not include Factor of Safety Weight of both object combined Engineering Analysis – Structure Tower Height Free Fall – No Air Resistance (Vacuum Conditions) Applies to All Objects: 𝑉𝑓 = ∆𝑡 = 2 ∗ 𝑔 ∗ ∆𝑦 + 𝑉𝑖 2 𝑉𝑓−𝑉𝑖 𝑔 Vi=0 g=32.2ft/s2 Example: y = 15 ft Vf = 31.081 m/s Free Fall –Air Resistance (Atmospheric Conditions) 𝑉∞ = 2 ∗ 𝑚 ∗ 𝑔/(𝜌 ∗ 𝐶𝐷 ∗ 𝐴) ρ is the Density of Air 𝐶𝑑 is the Drag Coefficient A is the Projected Area of the Falling Object ∆𝑡 = 𝑐𝑜𝑠ℎ−1 𝑒 ∆𝑦 −𝑔∗𝑉 ∞ 𝑉𝑓 = −𝑉∞ ∗ tanh(𝑔 ∗ 2 𝑡 ) 𝑉∞ ∗ 𝑉∞ /𝑔 Free Fall – Vacuum vs. Atmospheric Conditions Time vs. Height - Zoomed 5.0 4.5 4.0 Time (s) 3.5 Vacuum 3.0 Atmosphere-1" Steel Ball 2.5 Atmosphere-1.625" Steel Ball 2.0 Atmosphere-1.575" Ping Pong Ball 1.5 Atmosphere-Feather 1.0 Atmosphere-Paper 0.5 0.0 0 5 10 Height (ft) 15 20 Engineering Analysis - Air Control Ultimate Pressure & Gravity Error Effect Gravity Calculation with 1% Error Constant Acceleration Equations Assumes no air resistance / perfect vacuum 𝑥 = 𝑥0 + 𝑣0 𝑡 + 0.5𝑎𝑡 2 𝑔 = 2𝑥 𝑡2 , where x is position and t is time Error in Gravity 1% Error g = % Error x + 2(% Error t) % Error x: Laser % Error t: Laser & Pressure (Drag) Free Body Diagram of Object Force Balance 𝐹𝑦 = 𝑚𝑎 𝐹𝐷 − 𝑚𝑔 = 𝑚𝑎 At Terminal Velocity Acceleration = 0 𝐹𝐷 = 𝑊 At Vacuum Pressure, drag force = 0 −𝑚𝑔 = 𝑚𝑎, where a is downward (negative) Drag Force (Air Resistance) 𝐹𝐷 = 0.5𝜌𝑉 2 𝐶𝐷 𝐴 FD = Drag Force ρ = Air Density V = Velocity of Object CD = Drag Coefficient (Fudge Factor) A = Projected Area of Object 𝑃 𝑅𝑇 P = Air Pressure (Pa) R = Specific Gas Constant = 287.05 J/kg*K T = Air Temperature = 21°C = 274K 𝑘𝑔 −5 𝜌 = 1.185 ∗ 10 ∗𝑃 𝐽 𝜌= Objects to calculate gravity Not all objects may be suitable for gravity calculations Objects vary by their mass, projected area and drag coefficient Assumptions: Max Tube Height = 15 ft Ideal Gas Room Temperature Standard Gravity Error in Time vs. Chamber Pressure is as follows for each object: 1.625" Steel Ball 1" Steel Ball Ping Pong Ball Feather Paper Pressure (Pa) 50 100 2 10 500 101325 0.0000% 0.0000% 0.0000% 0.0001% 0.0005% 0.10% 0.0000% 0.0000% 0.0001% 0.0002% 0.0008% 0.16% 0.0002% 0.0010% 0.0049% 0.0099% 0.0495% 10.25% 0.0023% 0.0117% 0.0585% 0.1169% 0.5855% 106.83% 0.0130% 0.0650% 0.3254% 0.6514% 3.2801% 352.56% % Error in Time vs. Chamber Pressure (Graphically) % Error in Time Compared to Vacuum Fall Tiime % Error in Time vs. Chamber Pressure 4% 3% 1" Steel Ball Ping Pong Ball 2% Ping Pong Ball Feather Paper 1% 0% 0 100 200 300 Base Pressure (Pa) 400 500 600 Engineering Analysis – Laser Sensor Sensor Laser Distance Sensor • Specs • • • • • Micro-Epsilon ILR-1030 15m Range 4-20mA Output 10ms Response time Tolerance • Error in position • • +/- 5 mm (0.0164 ft) Error in time • none % Error in Gravity Summary 2 Pa 1.625" Steel Ball 10 Pa 50 Pa 100 Pa 500 Pa 101325 Pa 8ft 15ft 8ft 15ft 8ft 15ft 8ft 15ft 8ft 15ft 8ft 15ft 0.205% 0.109% 0.205% 0.109% 0.205% 0.109% 0.205% 0.110% 0.206% 0.110% 0.404% 0.309% 0.205% 0.109% 0.205% 0.109% 0.205% 0.109% 0.205% 0.110% 0.207% 0.111% 0.529% 0.433% 0.205% 0.110% 0.207% 0.111% 0.215% 0.119% 0.225% 0.129% 0.304% 0.208% 20.704% 20.609% 0.210% 0.114% 0.228% 0.133% 0.322% 0.226% 0.439% 0.343% 1.376% 1.280% 213.863% 213.767% 0.231% 0.135% 0.335% 0.239% 0.856% 0.760% 1.508% 1.412% 6.765% 6.669% 705.326% 705.230% 1" Steel Ball Ping Pong Ball Feather Paper Engineering Analysis - Air Control Evacuation Time Conductance The flow of air in a tube, at constant temperature, is dependent on the pressure drop as well as the cross sectional geometry. 𝐷4 𝐹1 Ṗ 𝐿 𝐶𝑉 = Viscous Flow: Pressure (micron) * Diameter (in) > 200 𝐷4 𝐹1 Ṗ 𝐿 𝐷3 𝐹2 𝐿 𝐶𝑇 = + Transitional Flow: 6.0 < Pressure (micron) * Diameter (in) < 200 𝐷3 𝐹3 , 𝐿 𝐶𝑀 = Molecular Flow: Pressure (micron) * Diameter (in) < 6.0 C = Conductance (cfm) Ṗ = Average Pressure(microns) = 𝑃1 −𝑃2 2 F1 = Viscous/Transitional Flow Scale Factor = 0.52 F2 = Transitional Flow Scale Factor = 12.2 F3 = Molecular Flow Scale Factor = 13.6 D = Pipe Diameter (in) L = Pipe Length (ft) Viscous Molecular Equivalent Pipe Length Pipe fittings can cause losses within a piping system These include: elbows, tees, couplings, valves, diameters changes, etc. Tabulated values for Le/D can be used to adjust L in the conductance equations D = Diameter of Pipe Le = Equivalent Length Total Length = L + Le1 + Le2 + Le3 + …. Effective Pump Speed SEff for each flow regime Viscous, Transitional, & Molecular 1 𝑆𝐸𝑓𝑓 = 1 𝑆𝑃 + 1 𝐶𝑛 + 1 𝐶𝑛−1 + ⋯+ 1 𝐶2 + 1 𝐶1 n = number of pipe diameters C = Conductance (cfm) 𝑆𝑃 = Given Pump Speed (cfm) 𝑆𝐸𝑓𝑓 = Effective Pump Speed for Tube Dimensions Evacuation Time 𝑡= 𝑉 𝑆𝐸𝑓𝑓−𝑉 ln 𝑃0 𝑃1 + 𝑉 𝑆𝐸𝑓𝑓−𝑇 l𝑛 𝑃0 = 760 Torr (Atmospheric) 𝑃1 = Viscous–Transitional Pressure 𝑃2 = Transitional-Molecular Pressure 𝑃3 = Ultimate Pressure 𝑃1 𝑃2 + 𝑉 𝑆𝐸𝑓𝑓−𝑀 l𝑛 𝑃2 𝑃3 VP6D CPS Vacuum Pump • Example: Single 6” x 15’ Tube 𝑡 = 7.81 𝑚𝑖𝑛𝑢𝑡𝑒𝑠 Pump used on left See Spreadsheet for: • Fittings • Individual conductance • Individual flow regime time 2 Stage Rotary Pump 15 micron Ultimate Vacuum Pump Speed – 6.25 cfm Price: $268.92 Engineering Analysis - Air Control Leak Rate Chamber Leak Rate Throughput, Q Units: (Pressure * Volume) / Time Pump Throughput, QP 𝑄𝑃 = 𝑆𝐸𝑓𝑓 ∗ 𝑃 Where: Seff = Effective Pump Speed P = Pressure Constants: • Chamber Volume • Temperature • Atmospheric Pressure • Leak Area Time Variables: • Mass Flow Rate • Chamber Pressure Leak Throughput, QL 𝑄𝐿 = Δ𝑃 Δ𝑡 Leak ∗V Where: dP/dt = Differential Pressure V = Chamber Volume Pump 𝑃𝐵𝑎𝑠𝑒 Δ𝑃 ∗𝑉 Δ𝑡 = 𝑆𝑒𝑓𝑓 𝑃𝑈𝑙𝑡𝑖𝑚𝑎𝑡𝑒 = 2𝑃𝑎 = 𝑃𝑚𝑖𝑛 How Leakage Affects Ultimate Pressure 30.00 25.00 Pressure (Pa) 20.00 15.00 10.00 5.00 Flow Regime Change 0.00 0.0 10.0 20.0 30.0 40.0 Leak Rate (Pa / min) Note: Assumes linear relationship (mass flow rate constant) 50.0 60.0 Engineering Analysis - Catching Mechanism Energy Dissipation Critical Dimensions of Impact Absorption material Critical Dimensions of Impact Absorption material 𝑚𝑎 𝑚𝑏= 𝐶𝑅 • Assuming a Object 1 mass of 2 lb. • Assuming a Coefficient of Restitution of 0.712 • Assuming a Ball Radius of 2in. Height of energy absorbing material = 4.19 in ̴ 5 in Mass= Volume x density Volume= Area x Height Area= Pi x Radius^2 Engineering Analysis – Piping System Critical External Pressure Pipe Critical Pressure Calculations Critical Pressure Calculations for Clear PVC P 14.7 psi v 0.37 E 429000 psi Formula PCrit=(2*E/(1-v^2))*(1/((OD/t)-1)^3) SCH 40 Pipe Maximum Pressure Size (in) OD (in) Thickness (in) Max Pressure (psi) Factor of Safety 6 6.625 0.28 85.43 5.81 8 10 12 8.625 10.75 12.75 0.322 0.365 0.406 57.98 43.16 35.37 3.94 2.94 2.41 Desired Factor of Safety = 3-4 Max Pressure Rating of Schedule 40 PVC*, from HARVEL Size (in) 6 8 10 12 Pipe Dimensions Courtesy of Engineeringtoolbox.com Max Pressure (psi) 90 58 49 42 *Specifications for white PVC Factor of Safety 6.12 3.95 3.33 2.86 Engineering Analysis – Structure Support Buckling Schematic Tube Pipe Riser Clamp • Worst case scenario: – 15’ Long PVC Schedule 40 – 8” Diameter – 10’ long square A513 tube • So 10’ of buckling length • Assumptions: Frame Pipe Riser Clamp – Weight of vacuum tube is split evenly between four connection points Depiction of Reaction Forces on Tube W/2 W /4 W /4 • Becomes an eccentric column loading problem because the weight of the tube is applied on one face of the support columns 10ft • 𝑓 𝐹 = − W/2 W /4 Eccentric Distance 𝐹 𝐴 W /4 𝑆𝑦𝑐 𝑐 𝑙 𝐹 1+ 𝑒∗ 2 ∗sec[ ] 2𝑘 𝐴∗𝐸 𝑘 • Requires numerical methods root finding techniques Methods using Matlab: F/A-Syc/(1+(e c/k2) sec((l/(2 k)) sqrt(F/(A E)))) 5 x 10 Parameters: • 10ft long steel tube 1.5 1 0.5 • 1-1/2” square • 0.120” wall • A513 steel 0 -0.5 -1 -1.5 1200 1300 1400 1500 1600 F 1700 1800 1900 >> Buckling_False_Position >> Buckling_Bisection F (lbf) is: 1617 F (lbf) is: 1616 FOS is: 84 FOS is: 84 The percent error is: 0.006 The percent error is: 0.038 2000 Support Buckling Results • We achieve a FOS well over what we would ever need for the selected support frame in buckling under worst case scenario • Our frame can support the weight of the tube, and is feasible • We can, if desired, reduce frame cross-section size and thickness if further analyses show large FOS as well Engineering Analysis – Structure Leg Center Deflection Schematic Worst case scenario: 15’ Long PVC Schedule 40 8” Diameter 10’ long square A513 tube1-1/2” 0.120” wall A513 steel Assumptions: Weight of vacuum is halved between the two legs, as is the upper frame structure 1 foot long leg Reactions and Deflection In the diagram below, dimension a is the distance to the front support block and b is to the center of the wheel axel. F includes half the weight of the tube and the upper support structure Result: ymax=-3.30E04 inches Engineering Analysis Summary Proposed Requirement Metrics Tower height: up to 5 meters (~16ft) Tower size: 6” Diameter Number of Towers: 1 Pump Speed: 6.25 cfm Pump Type: 2 stage Rotary (mechanical roughing pump) Evacuation Time: 5.25 mins Ultimate Pressure: 15 microns (0.015Torr or 2Pa) Negative (Critical) Pressure – Factor of Safety: 3.94 No Isolation Valves Manual Object Lifting Electromagnetic Release Mechanism Mobile Support Structure Test Plan # Test Description Comments/Status 1 Drop Test Test Fall Time of Selected Objects is Atmosphere 2 Energy Dissipation Control Drop heaviest object 3 Test Release Mechanism Drop Object from any height 4 Position sensor accuracy for objects Sensors can be mounted / tested without tube 5 Ultimate pressure Considering pump size / leaks/ chamber volume 6 Pressure gage accuracy Connect vacuum to pressure gage only 7 Temperature gage accuracy Calibrate Sensor 8 DAQ device inputs Position and time (from sensor(s)) 9 Computer Software Outputs Computer outputs from on DAQ & human inputs 10 Tower stability Simulate maximum applied forces 11 Extra vacuum tests How things react inside our vacuum Drop Tower Piping Schematic Bill of Materials: 6” Diameter by 10ft Tall Item Pipe Union Fitting Reducing Pipe Tee* Polycarbonate Sheet Size (in) 6in 6"slip x 6"slip 6in-6in-2in FPT 1/2" THK Item CPS Vacuum Gauge Temperature Gage Laser Distance Sensor Temperature reader DAQ Range 0 micron - atm; 1/4 SAE F 1m-2m 0.2m - 15m (-50) to 1300 °C 8 Analog inputs Item 2 Stage Rotary Pump 0.75" Diameter Round Electromagnet EM100 Strike Plate Flat Handle Plug 2-Pole, 2-Wire Pan Head Mach. Screw Single Device High Performance Driver Everbilt 3/4 in. Corner Braces (4-Pack) Everbilt 1-1/2 in. Hinges (2-Pack) Lexan Plastic Sheet Length 10 ft n/a n/a 12" x 24" Rating 15 Microns Tower Pipes & Fittings & Gaskets Approx. Weight Material Rating Vendor 35.3 Clear PVC SCH40 clearpvcpipe white PVC SCH40 mc master 1.35 lbs White PVC SCH40 pvcfittingsonline Polycarbonate n/a mc master Gages, Sensors, & DAQ Vendor Part # / Size Approx. Weight (lbs) Century Tool VG200 0.5 National Instruments Micro-Epsilon ILR-1030 National Instruments Input/Output Size 1/2in SAE Pump & Electromagnets Voltage Flow Rate 110-120V / 220V 50/60Hz 6.25 CFM Part # 1395-061 4880K311 402-528 8574K45 Price for 1 $146.45 $30.00 $545.00 $16.82 $149.00 Power Supply Vendor 120V rms @ 60Hz CPS products APW Company APW Company APW Company APW Company APW Company Home Depot Home Depot Zoro Tools Price for 1 $410.40 $88.44 $37.00 $54.22 Quantity Price per Qty 1 $410.40 2 $176.88 1 $37.00 1 $54.22 Subtotal: $678.50 Quantity Price per Qty 1 $146.45 1 $30.00 1 $545.00 1 $16.82 1 $149.00 Subtotal: $887.27 Part # / Size Price for 1 VP6D EM075-12-222 SP-100 MISC-017 SCRM-019 EMD-01-TE-PH 13542 15377 GRA0112001012 $268.92 $29.24 $6.79 $1.99 $0.10 $123.00 $1.97 $2.27 $13.59 Quantity 1 1 1 1 4 1 1 1 1 Subtotal: Price per Qty $268.92 $29.24 $6.79 $1.99 $0.40 $123.00 $1.97 $2.27 $13.59 $448.17 Bill of Materials Con’t: 6” Diameter by 10ft Tall Item slip x slip, 90° Elbow Brass Connector: SAE x NPT Brass Adapter: SAE x NPT 90° Elbow: FPT x MPT Reducer Bushing Slip x FIPT Pipe Hose Male Barbed Hose Fitting Ball Valve Brass Cross NPT Hex Nipple Adapter Dimensions 2" 1/4" SAE M - 1/2" MPT 1/2" SAE F - 1/2" MPT 1/2" FPT x 1/2" MPT 2" slip x 1/2" Fipt 2" 3/4"ID - 1"OD 3/4"Hose - 1/2"NPTF 1/2" FPT 1/2" FPT 1/2" MPT x 1/2" MPT Item Size (in) 1-1/2 X 1-1/2 Square Metal Tubing Riser Clamp (Includes Bolts) 6" Item Polystyrene Beads Bulk Head Fittings on/off Switch (for release mech.)* Hinges (for release mech.) Computer Multipositional Ladder PTFE Pipe tape Metal Hose Holder Clamp (5 qty) Hose Clamp: Worm Drive (10 qty) Clear Cement/Glue Vacuum Sealant Length n/a n/a n/a n/a n/a 10 ft 10 ft n/a 2 5/16" n/a 1.81" Pump Piping, Fittings, and Hose Vendor Material SCH40 pvcfittingsdirect White PVC n/a fastenal brass n/a fastenal brass n/a fastenal brass SCH40 pvcfittingsdirect White PVC SCH40 lowes White PVC 29.9"Hg Vacuum mc master Polyethlene n/a mc master brass 29.9"Hg Vacuum mc master brass 1200PSI fastenal brass 1200PSI fastenal brass Thickness (in) 0.12 Dimension 3 ft3 n/a n/a n/a n/a 22ft max 50ft roll 1" hose 15/16" - 1 1/2" 1 quart n/a Rating Length (ft) Misc. Vendor Approx Weight 6 lbs n/a n/a n/a n/a n/a n/a n/a n/a n/a n/a Frame Components Vendor Part # / Size 12 Metals Depot T111211 Pex Supply 126B96 Hayneedle pvcfittingsdirect amazon homedepot n/a homedepot mc master mc master mc master pvcfittingsdirect Ideal Vacuum products Final Total: $2558.56 Material Polystyrene n/a n/a steel n/a aluminum PTFE Aluminum 301 Stainless Steel Clear Cement thermal-plastic Part # / Size 406-020 69535 440292-131280 424279-131280 438-247 23832 50375K57 5346K68 47865K23 440095-131280 440049-131280 Price for 1 $39.12 $8.95 Part # / Size HN-CT110 n/a n/a 1.5" n/a MT-22 4591K13 8863T58 5388K24 n/a n/a Price for 1 $1.93 $3.69 $4.61 $9.48 $2.21 $6.97 $9.00 $3.69 $9.84 $19.09 $5.33 Quantity 2 2 Price for 1 $29.99 $13.16 $6.73 $2.27 $0.00 $189.00 $3.05 $6.59 $7.37 $38.02 $49.75 Quantity Price per Qty 1 $1.93 1 $3.69 1 $4.61 1 $9.48 1 $2.21 1 $6.97 1 $9.00 2 $7.38 2 $19.68 1 $19.09 2 $10.66 Subtotal: $94.70 Shipping Price per Qty 133.67 $211.91 $17.90 Subtotal: $229.81 Quantity 1 2 1 2 1 1 1 1 1 1 1 Subtotal: Price per Qty $29.99 $26.32 $6.73 $4.54 $0.00 $189.00 $3.05 $6.59 $7.37 $38.02 $49.75 $361.36 Drop Tower Price Comparison Drop Tower Price Comparison Tower Diameter 6in Tower Height 10ft 15ft 8in $2,756.72 $3,759.71 $3,167.12 $4,375.11 Using the 6in diameter by 15ft tall tower as a datum, the chart shown below was produced. Drop Tower Price Comparison Tower Diameter 6in Tower Height 10ft 15ft $410.40 8in -$592.59 datum ($0) -$1,207.99 Questions?