Anthony Beeman Second Progress Report

advertisement

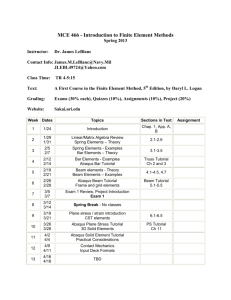

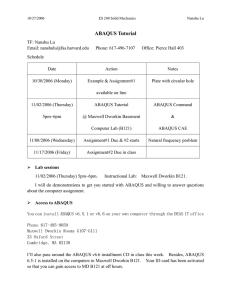

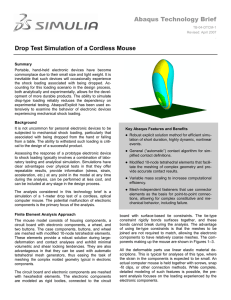

Anthony Beeman Since the project proposal submittal on 9/21/15 I began work on the Abaqus Kinematic model utilizing join, hinge, and beam elements. Building the model- A model was successfully created using the join, hinge, and beam connectors with 0 pivot errors. ◦ Zero pivot errors occur in Abaqus when the model is over constrained at a specific degree of freedom. This can provide inaccurate results as the model will still run to completion. With the model successfully created I began applying one angle per analysis step and validated the connector was being utilized properly. The FEM behaved as expected. Next, I applied up to three rotations per joint per analysis step. This resulted in a much different final joint location than expected. ◦ I assumed the angles would be projection angles or 3-1-3 Euler angles. Conclusions- Abaqus does not parameterize compound angles as I expected. Abaqus Joint Connector Model Knowing that Abaqus could rotate 1 angle per analysis step accurately I began looking for alternative methods to parameterize the model. Denavit–Hartenberg (DH) parameters- DH parameters consists of four parameters associated with a particular convention for attaching reference frames to the links of a spatial kinematic chain, or robot manipulator. This method is commonly used in robotics to define a robotic tool tip position, velocity, and acceleration as a function of each link’s joint angles and time. The DH parameter method chains revolute and prismatic joints to model robotic kinematics. ◦ Therefore, setting up the Abaqus connectors identical to the DH parameters would ensure proper compound joint rotations as a function of time. DH Parameter Link Example A planar selected to to simplify the motion two bar mechanism was model the kinematic systems the problem by constraining to two degrees of freedom. The planar two bar mechanism is composed of two rigid bodies, the upper arm and fore arm, which are connected to a ground. Each link is connected with revolute joints and is free to rotate about the z axis. Mathcad files were created to calculate joint velocities, accelerations, and joint torques. ◦ Joint velocities shall be used as connector velocity boundary conditions within the FEA A 4 step Abaqus FEA was created to model the planer two bar mechanism using DH-parameterization. ◦ Each degree of freedom can be modified independently and provides rotations as expected. Throwing Motion Represented as a Planar 2 Bar Mechanism Kinovea Software was utilized to analyze film of various NFL quarterbacks throwing the football. Kinovea’s angle measurement tool was utilized to determine joint angles at key positions in the overhead throw Kinovea’s Angle Measurement Tool Abaqus, was used to create the Finite Element Model and perform the kinematic analysis. The Finite Element Model was constructed utilizing a series of hinge and beam connector elements. Inertial mass properties have been included in the model by separating the beam elements into two equal segments. Display bodies were included in order to provide a physical representation of the human arm as it transitions from each of the four phases of the throwing movement. The series of Abaqus connector representing the throwing arm are illustrated to the right Stationary parts such as the head, left arm, and lower body were modeled for information but motion was restricted for this analysis. Abaqus FEM The Abaqus Finite Element analysis is comprised of four unique steps in order to simulate the kinematics of throwing a football. These steps include: ◦ Foot contact ◦ Maximum external rotation ◦ Ball release ◦ Follow through step Each step was modeled as static general step with non-linear geometry turned on. ◦ Note: It is important to note that non-linear geometry was turned on in the FEM because large displacements take place. This ensures the FEM accurately determines the final position of the elements after large displacements occurs. The table below illustrates each of the four steps created in the FEM, the time duration, and the number of output database frames for each step. Step 0 Step 1 Step 2 Step 3 Step 4 Maximum Variable Initial Foot External Step Contact Rotation Ball Release Through Time (sec) 0 1.0 0.5 0.25 0.25 Increment size 0 0.10 0.05 0.05 0.05 Number of - 10 10 5 5 Output Database (ODB) frames Follow Foot Contact M.E.R. Release Add more detail to each report section Discuss Results from the FEM ◦ X & Y position as a function of time ◦ X & Y Force as a function of time ◦ Shoulder Elbow Joint Torque as a function of time Explain how DH parameterization is an excellent option when modeling complex biomechanical movements. Explain how to increase the number of degrees in freedom in the throwing motion to increase model accuracy. 5 DOF Arm Modeled Using DH Parameters