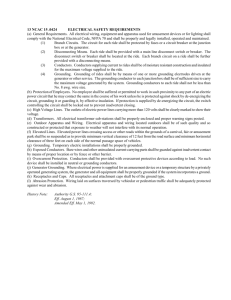

The Evaluation of Steel Conduit and EMT as

advertisement

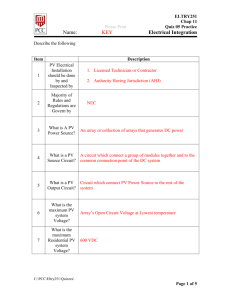

The Evaluation of Steel Conduit and EMT as Equipment Grounding Conductors Program Outline • NEC Requirements – RMC, IMC and EMT – Copper and Aluminum Conductors • • • • • • Georgia Institute of Technology Research GEMI Analysis Software Sizing the EGC Comparison of NEC and GEMI Software Summary of Results Computer Exercises Grounding & Bonding is Paramount to a good installation Protection against •Lightning & Voltage Surges •Short Circuits •Ground Faults •Limit Fire & Shock Hazards NEC Compliance NEC 110.10 “The overcurrent protective devices, the total impedance, the component (equipment) short-circuit current rating, and other characteristics of the circuit to be protected shall be selected and coordinated to permit the circuitprotective devices used to clear a fault to do so without extensive damage to the electrical component (equipment) of the circuit”. . . NEC 110.10 “This fault shall be assumed to be either between two or more of the circuit conductors or between any circuit conductor and the (equipment)grounding conductor or enclosing metal raceway. Listed products applied in accordance with their listing shall be considered to meet the requirements of this section.” 2008 NEC® • Verification of an adequate and safe effective fault return path (EGC) is a requirement. • All metal parts that may become a part of this path must be bonded (connected) together. 300.10 • Metal raceways, cable armor, and other metal enclosures for conductors shall be mechanically joined together into a continuous electrical conductor and shall be connected to all boxes, fittings, and cabinets so as to provide effective electrical continuity. Unless specifically permitted elsewhere in this Code, raceways and cable assemblies shall be mechanically secured to boxes, fittings, cabinets, and other enclosures. 300.12 • Mechanical Continuity — Raceways and Cables. • Metallic or nonmetallic raceways, cable armors, and cable sheaths shall be continuous between cabinets, boxes, fittings, or other enclosures or outlets. NEC Article 250 is Unique • 250.4(A) & (B) Contains the General Performance Requirements for Grounding and Bonding. • The remainder of Article 250 contains prescriptive methods to comply with these performance requirements. NEC Article 250 Organization I II III IV V General Circuit and System Grounding Grounding Electrode System and Grounding Electrode Conductors Enclosure, Raceway and Service Cable Grounding Bonding VI Equipment Grounding and Equipment Grounding Conductors VII VIII IX X Methods of Equipment Grounding Direct Current Systems Instruments, Meters, and Relays Grounding of Systems and Circuits of 1kV and Over NEC 250.118 “Types of Equipment Grounding Conductors” • “The equipment grounding conductor run with or enclosing the circuit conductors shall be one or more or a combination of the following:” NEC Article 250.118 (1) A copper, aluminum or copperclad aluminum conductor (2) Rigid metal conduit (3) Intermediate metal conduit (4) Electrical metallic tubing PLUS . . . 10 Other wiring methods NEC 250.4(A)(5) • “Effective Ground-Fault Current Path. Electrical equipment and wiring and other electrically conductive material likely to become energized shall be installed in a manner that creates a low-impedance circuit facilitating the operation of the overcurrent device or ground detector for high-impedance grounded systems.” • “It shall be capable of safely carrying the maximum ground-fault current likely to be imposed on it from any point on the wiring system where a ground fault may occur to the electrical supply source.” NEC 250.4(B)(2) • “Bonding of Electrical Equipment. “Non-currentcarrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment shall be connected together and to the supply system grounded equipment in a manner that creates a low-impedance path for ground-fault current that is capable of carrying the maximum fault current likely to be imposed on it.” Paths to Ground Grounded Neutral Grounded (Neutral) Metallic Raceway (EGC) Grounded Conduit Equipment Grounding Conductor Equipment Grounding Conductor (EGC) Grounding Electrode Conductor (GEC) Grounding Conductor Ground Electrodes Grounding Electrodes NEC 250.24(A)(5) • “Load-Side Grounding Connections. A grounded conductor shall not be connected to normally noncurrent-carrying metal parts of equipment, to equipment grounding conductor(s), or be reconnected to ground on the load side of the service disconnecting means except as otherwise permitted in this article.” 250.122 Size of Equipment Grounding Conductors • (A) General. Copper, aluminum, or copper-clad aluminum equipment grounding conductors of the wire type shall not be smaller than shown in Table 250.122 • Where a cable tray, a raceway, or a cable armor or sheath is used as the equipment grounding conductor, as provided in 250.118 and 250.134(A), it shall comply with 250.4(A)(5) or (B)(4). Table 250.122 Table 250.122 Minimum Size Equipment Grounding Conductors for Grounding Raceway and Equipment Rating or setting of Automatic Overcurrent Device in Circuit Ahead of Equipment, Conduit, etc., Not Exceeding (Amperes) Size (AWG or kemil) Copper Aluminum or Copper-Clad Aluminum* 15 20 30 14 12 10 12 10 8 40 60 100 10 10 8 8 8 6 200 300 400 6 4 3 4 2 1 500 600 800 2 1 1/0 1/0 2/0 3/0 1000 1200 1600 2/0 3/0 4/0 4/0 250 350 2000 2500 3000 4000 5000 6000 250 350 400 500 700 800 400 600 600 800 1200 1200 Note: Where necessary to comply with 250.4(A)(5) or (B)(4), the equipment grounding conductor shall be sized larger than given in this table. System Grounding Connections 250.24(A)(5) Courtesy of IAEI Development of GEMI Program • Validation Needed for Existing Data Soares Book on Grounding (Tables) Safe lengths for copper and aluminum conductors Safe lengths for Rigid metal conduit Intermediate metal conduit Electrical metallic tubing R.H. “Dick” Kaufman studies What is “GEMI”? Grounding and ElectroMagnetic Interference Analysis Software • Phase I: Grounding • Phase II: EMF/EMI GEMI Phase One Performance of Grounding Paths This research is the first update in forty years on the impedance and permeability of steel conduit. GEMI Background • 1992 Grounding Study Initiated at Georgia Institute of Technology • 1994 Phase I completed (Grounding Study) “Modeling and Testing of Steel EMT, IMC and Rigid Conduit” • 1997 Phase II completed “Modeling and Evaluation of Conduit Systems for Harmonics and Electromagnetic Fields” • 1999 GEMI software – Windows version • 2002-04 GEMI updates GEMI Phase I Key Issues Examined • Are steel Rigid, IMC and EMT effective equipment grounding conductors? • What length of run can be safely installed? • Does supplementary EGC lengthen the run? About the Project • In-Laboratory Resistance & Permeability Tests • Computer Modeling • Full Scale Field Testing • Written Report • User Software Released • IEEE Paper Illustration of Kearney Laboratories’ Facility Transformer Kearney Laboratory transformer and control room in McCook, IL Kearney Lab testing facility Test blocks and leads to Transformer Full Scale Test Set-up 7" Figure 5.2 Illustration of the layout of ten runs of Steel Conduit. Power conductors were enclosed but not shown. Total length of each conduit run is 256 feet. Wood blocks were used to space the steel. 1/2" EMT 3/4" EMT 3/4" IMC 3/4" GRC 2" EMT 2" IMC 2" GRC 3" EMT 3" IMC 3" GRC Fittings Used in the Testing • Tests at both 120 & 277 volts to ground were run using zinc die-cast and steel set-screw and compression couplings with no significant difference in the overall impedance. Grounding Concerns Load (a) Load (b) Load (c) Load (d) (a) Single Phase Circuit without Ground Conductor (b) Single Phase Circuit with Ground Conductor (c) Three Phase Circuit without Neutral (d) Three Phase Circuit with Neutral NEC Validation • Validates 250.118 • Safe Lengths for Rigid Steel Conduit Intermediate Metal Conduit Electrical Metallic Tubing • Validates Table 250.122 • Safe Lengths for Copper & Aluminum conductors GEMI Opening Screen Single Circuit Analysis Maximum System Length 40 Volt Arc - 400% of Protective OC Device • The software predicts maximum safe circuit lengths. • Rigid Steel Conduit, IMC, and EMT • Copper and Aluminum Conductors • Line to ground faults • Line to line or line to neutral faults Note: All other paths must be considered to establish the limiting condition. Each additional ground return path reduces the overall impedance. Steel Conduit or Tubing Parameters Select Parameters • Select type of conduit or tubing • Size • Temperature • Copper or Aluminum Conductors • Type and size • Temperature • Fault Clearing Current • Based on the overcurrent device • Check MFG Trip curves (4 – 5 x the OC rating) • Circuit Voltage to ground • Arc Voltage • 40 Volts unless you have different information • A bolted fault is unlikely Click on “Update” 289.88 404.80 Arcing Fault Compare Allowable Safe Lengths Fault Currents Are Low 141.15 Grounding Concerns Load (a) Load (b) Load (c) Load (d) Summary of Key Findings • Steel EMT, IMC and Rigid conduit meet NEC requirements for EGCs. • Comparably sized steel EMT, IMC and Rigid conduit allow flow of higher fault current than aluminum and copper EGCs. • Steel EMT, IMC and Rigid conduit provide low impedance path to ground. • Facilitate operation of OC devices in runs not exceeding maximum allowable lengths detailed in report Summary of Key Findings • Supplementary equipment grounding conductors, when participating in the fault circuit, reduce the overall impedance. . . • Do not add to safety in phase to neutral fault • May increase the allowable length of steel conduit, dependant on size and system design • Steel conduit is not the limiting factor in a conductor to neutral fault Start Program Analysis of Specific Systems Utility Substation 3-Phase Feeder 1-Phase Lateral C A Load B Load Examples of Maximum Length Equipment Grounding Conductor (Steel EMT, IMC, GRC, and Copper, Copperclad or Aluminum Wire) Computed As A Safe Return Fault Path To Overcurrent Device Based on 1994 Georgia Tech Software (GEMI windows 1.1) With an Arc Voltage of 40 and 4 IP at 25° C Ambient 120 Volts to Ground (1) (1) (1) Overcurrent 400% Circuit EMT, IMC Equipment Length of Length of Length of Copper Aluminum Device (4IP) Conductor GRC Grounding EMT Run IMC Run GRC Run Grounding or Copperclad Rating Overcurrent Size Trade Conductor Computed Computed Computed Conductor Grounding Amperes Device AWG-kcmil Size Size Maximum Maximum Maximum Conductor (75° C) Rating Copper Copper Max Max Amperes or or Run Run Aluminum Aluminum (In Feet) (In Feet) (In Feet) (In Feet) (In Feet) 20 80 12 1/2 --395 398 384 ----20 80 12 --12 ------300 --20 80 10 AL --10 AL --------293 30 120 10 1/2 ----383 ------30 120 10 3/4 --404 399 386 ----30 120 10 --10 ------319 --30 120 8 AL --8 AL --------310 40 160 8 3/4 ----414 ------40 160 8 1 --447 431 418 ----40 160 8 --10 ------294 --40 160 8 AL --8 AL --------232 60 240 6 1 --404 400 382 ----60 240 6 --10 ------228 --60 240 4 AL --8 AL --------221 100 400 3 1 1/4 --402 397 373 ----100 400 3 --8 ------229 --100 400 1 AL --6 AL --------222 200 800 3/0 2 --390 389 363 ----200 800 3/0 --6 ------201 --200 800 250 AL --4 AL --------195 (1) Per NEC Table 250-95. Applicable to non-metallic conduit runs. * NEC Wire Fill Table Permits Smaller Conduit Size Note: Software is not limited to above examples Examples of Maximum Length Equipment Grounding Conductor (Steel EMT, IMC, GRC, and Copper, Copperclad or Aluminum Wire) Computed As A Safe Return Fault Path To Overcurrent Device Based on 1994 Georgia Tech Software (GEMI 2.3) With an Arc Voltage of 40 and 4 IP at 25° C Ambient 277 Volts to Ground (1) (1) (1) Overcurrent 400% Circuit EMT, IMC Equipment Length of Length of Length of Copper Aluminum Device (4IP) Conductor GRC Grounding EMT Run IMC Run GRC Run Grounding or Copperclad Rating Overcurrent Size Trade Conductor Computed Computed Computed Conductor Grounding Amperes Device AWG-kcmil Size Size Maximum Maximum Maximum Conductor (75° C) Rating Copper Copper Max Max Amperes or or Run Run Aluminum Aluminum (In Feet) (In Feet) (In Feet) (In Feet) (In Feet) 20 80 12 1/2 --- 1170 1179 1140 --- --- 20 80 12 --- 12 --- --- --- 890 --- 20 80 10 AL --- 10 AL --- --- --- --- 870 30 120 10 1/2 --- --- 1135 --- --- --- 30 120 10 3/4 --- 1199 1182 1143 --- --- 30 120 10 --- 10 --- --- --- 946 --- 30 120 8 AL --- 8 AL --- --- --- --- 920 40 160 8 3/4 --- --- 1228 --- --- --- 40 160 8 1 --- 1326 1276 1239 --- --- 40 160 8 --- 10 --- --- --- 871 --- 40 160 8 AL --- 8 AL --- --- --- --- 690 60 240 6 1 --- 1197 1186 1131 --- --- 60 240 6 --- 10 --- --- --- 676 --- 60 240 4 AL --- 8 AL --- --- --- --- 657 100 400 3 1 1/4 --- 1192 1176 1107 --- --- 100 400 3 --- 8 --- --- --- 680 --- 100 400 1 AL --- 6 AL --- --- --- --- 659 200 800 3/0 2 --- 1157 1155 1077 --- --- 200 800 3/0 --- 6 --- --- --- 598 --- 200 800 250 AL --- 4 AL --- --- --- --- 578 (1) Per NEC Table 250-95. Applicable to non-metallic conduit runs. * NEC Wire Fill Table Permits Smaller Conduit Size Note: Software is not limited to above examples Questions www. http://steeltubeinstitute.org/steel-conduit/ Thank You This Software, Supporting Reports, and other material related to this presentation available on the website; www.steelconduit.org.