fst 510 nigeria's food and industrial raw materials sourcing

advertisement

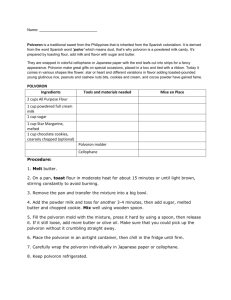

FST 510 NIGERIA’S FOOD AND INDUSTRIAL RAW MATERIALS 3 Units Part 1 Dr Mrs J.M. Babajide Department of Food Science and Technology, University of Agriculture, Abeokuta Course requirements: • CAT: 30% (Test 20% & assignment 10%) • Exam: 70% • 70% Class attendance compulsory INTRODUCTION Definition of Food raw material - an input into a processing operation to obtain a product. Raw materials can be divided into four (4) major classes: 1. Unprocessed agricultural products: which are usually in their natural state e.g. cassava, yam, grains, fruits, vegetables etc. 2. Semi-processed agricultural products: in form of dry-cocoa beans, dry sugar, pasteurized milk, grain flour, cocoa mass, malted grains etc. 3. Finished products:- of a particular industry can serve as material or ingredient for another industry e.g. refined granulated sugar, starch, Ascorbic acid, flavour etc. 4. Bye-product or effluent: of an industry can serve as input for another industry e.g. molasses can be used for the production of alcohol and yeast, while biscuit dust can be used for the production of animal feed. THE NIGERIAN FOOD INDUSTRIES • The food and beverage industry is virtually the largest of all the sectors of Manufacturers’ Association of Nigeria (MAN). • Food and beverage industries constitutes various sub-sectors such as brewery, soft drink, flour-mill, cereal and bakery products, Dairy products, animal feeds (livestock and fishery), meat and meat products, tea and coffee, sugar and sugar confectioneries margarine, edible oils, root and tubers, fruits and vegetables, spices and flavours. However, to facilitate a streamline presentation, the Nigerian food industries can be divided into 2 major categories: a. Milling industries: flour mills, rice mills, edible oil mills etc. b. Processing industries: beverages, cereal products, dairy products, confectionery, fruit and vegetable products, meat and poultry products etc. The milling industries require mainly agric products and the outputs are generally finished products offered for sale as domestic food items after suitable food packaging. The food processing industries require derivative secondary produce, in some cases, require tertiary forms of agric and synthetic raw materials. There are three (3) broad categories of raw materials namely: Primary Agric produce, Secondary and Tertiary raw materials. KEY RAW MATERIALS USED IN FOOD INDUSTRIES S/N 1. 2. 3. SECTOR Beer/Brewery industry Soft drinks Cereals and Bakery products 4. Dairy products 5. 6. 7. 8. 9. 10. 11. 12. PRIMARY Barley, sorghum, maize, rice Wheat, maize sorghum, cassava flour, starch, other cereal flour. Fresh milk/milk powders SECONDARY Sugar, enzymes Sugar Sugar, enzyme TERTIARY Hops and additives Concentrates Salt, flavour additives, vitamins or Flavours, vitamins fat, oil, Milk fat vegetable butter enzyme, dextrose Cocoa and Chocolate products Cocoa powdered, milk, sugar Egg powder glucose, corn starch Wine and Distillers Grape fruits, molasses, palm Other fruits wine, concentrate, flavouring Animal feed Maize, soybean, cassava, oil Other cereals, seed, cake, spent grains offals, additives Tea and Coffee Tea leaves, coffee beans, lemon Chicory grass Sugar and sugar confectionery Sugar cane, glucose, cassava Gum arabic, starch enzyme Fruits and vegetable products Fruits, vegetables, fruit Essential oils, concentrates sugars Spices anf flavouring Hydrolysed vegetables, nitrates, locust bean, pepper, ginger Meat and fish products Cattle, beef fish, pork, poultry, Snail, osyster, shrimps games 13. Margarine and edible oils 14. 15. 16. Root and Tubers products Flour millers Miscellenaous Oil seeds (g/nut, soybean, sun flower, oil palm etc) Yam, cassava, Irish potato etc. Wheat, maize ,sorghum etc. Plantain, banana, sweet corn, other staple food. Preservatives Supplements and minerals) - (vitamins Colouring, flavourings, essential oils. Flavourings preservatives Flavours, extract of spices from leaves Nitrates, extenders, additives, vegetable oil, preservatives. Preservatives Preservatives Preservatives. PRIMARY AGRICULTURAL RAW MATERIALS AND THEIR AVAILABILITY Raw material Wheat grains Maize grains Sorghum grains Rice grains Cocoa beans Coffee beans Tomato fruit Pepper Pineapple Mango Cassava Yam Plantain Oil seeds Fresh milk Requirement Production H H H House hold use L L L H H L H H H H H H H H H H L L H H L L H H H H L L L L H H L L H H L H/L L L H H/L Surplu Defici s t D S* D S* S* S* S S* - Where H = High, L – Low, S = Surplus, D = Deficit, S*= surplus during their season but deficit during off season. D D D D D D D • The table above shows the industrial primary agricultural raw materials and their availability. Due to the fact that a considerable portion of the agricultural produces are lost before, during and after harvest to pest or diseases and inadequate transportation procedures, we could have inadequate productions. A great proportion of the agric produce are consumed directly as domestic product thus the industrial processors have problem with local sourcing of these raw materials e.g. maize. • Further discussion will be taken in the class REPORTED POST-HARVEST LOSSES OF AGRICULTURAL RAW MATERIALS IN NIGERIA Commodity %loss Yam 30 – 50 Maize 25 – 30 Sorghum 37 Cowpea 5 Fruits and 20 – 80 Vegetables Onion, tomato, 9 – 17 pepper, plantain Plantain 20 – 80 As reported by Raw Material Research and Development Council and Federal Ministry of Agriculture DERIVED FORMS OF RAW MATERIALS AND THEIR AVAILABILITY IN NIGERIA S/N 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. MATERIAL REQUIREME NT (H/L Cereal flour High Baking yeast H Veg. fat and oil H Sugar H Soft drink conc H Cocoa powder H Cocoa butter L Glucose H Malt extract L Egg powder L Corn Starch L Milk powder H Butter oil L Hydrolysed veg. L protein Chicory L Oilseed cake L Fish meal L Food colouring L Food flavouring L PRODUCTION (H/L) Low L/Nil L L NIL L L L/NIL NIL L/NIL L/NIL NIL NIL NIL NIL L L NIL NIL SURPLUS DEFICIT D D D D D D D D D D D D D D D D D D D SUBSTITUTES OR ALTERNATIVES FOR IMPORTED RAW MATERIALS IN NIGERIA S/N 1. 2. 3. 4. IMPORTED RAW MATERIAL Malted barley Hops Egg powder Enzymes 5. 6. 7. 8. 9. 10. 11. Additives Wheat/wheat flour Milk/milk powder Fat and butter oil Flavouring Corn starch Gum base 12. 13. Fish, meat and poultry Tea leave 14. Dextrose, glucose 15. Hydrolysed veg. oil LOCAL SUBSTITUTE Maize, sorghum, rice Bitter leaf Malted grains for production of specific enzymes Local wheat production but inadequate Local fresh milk (inadequate), soy milk Local flavours for specific flavours. Modified cassava flour Gum Arabic (need to be processed into well acceptable form) Local production (inadequate) Use of other leaves such as lemon grass (inadequate) Local sources available. Hydrolysed cassava starch but inadequate Soybeans, groundnut, locust beans. METHODS OF SOURCING FOR RAW MATERIALS • In sourcing, there is a general principle that most industries use. • The aim of sourcing is to obtain the best quality raw material at a most economical rate. • In Nigeria, the approach used are in two general ways, namely Direct, indirect or combination of the two. Direct sources: This requires the establishment of raw material purchasing department in the industry which is charged with the responsibility of getting the required raw material by the industry. Example of such industry is Nestle Nigeria Plc which produce maize and soybeans. Where direct sourcing is used, the problem of monitoring specification of raw material can be reduced. This is because such quality specifications are inbuilt into the production system. When such materials have to be purchased, the raw material specifications must be given to the supplier. Indirect sources:- These utilize sourcing agents. This method is used by many industries. The sourcing agent can be in the following forms: 1. Contractual Appointment to framers or cooperate bodies. Such as appointments are generally guided by relevant legal proceedings, otherwise, it may fail. The advantage of this method is that it ensures stable price of raw material within the period of agreement. Also, it ensures a ready market to the farmers within the same period. 2.Use of cooperative societies:- This is similar to contractual agreement except that it involves many people coming together. It involves collection of raw material from individual seller or producer by the cooperative society and it is sold to the company that required the raw material e.g. the Cocoa Producers Association of Nigeria at various local levels. In this situation, there may be slight variation in the pricing system. 3.Use of individual suppliers which have links with the purchasing department of the industry. Here, individuals are given allocation of supply orders on certain quality and quantity of raw material to be purchased by the company. However, the supply is subjected to satisfactory delivery within a certain period and acceptable quality. In this case, discontinuation of the supply order is at the risk of the company. Price variation is a major problem which depends on the supplier. QUALITIES OF A GOOD SOURCING AGENT A good sourcing Agent: • Should be knowledgeable about the nature (biological, physical, chemical properties) of the raw material. • should be familiar with and understand the various classes of the food. The handling practice that can lead to deterioration of the material. If not, should be trained and educated on what causes deterioration of the material. • should understand the basis processing operation which the raw material will undergo before getting the finished product. • should be an informed person in terms of agricultural practices, the location and the trade of such material. • should assess the quality of the raw material thus, ensure the quality specification required by the company. CONSTRAINTS AND PROSPECTS OF LOCAL RAW MATERIAL SOURCING Constraints 1. Availability of local raw material for industry Many of the raw materials, especially seasonal ones such as maize, yam, fruits are inadequate for industries due to the fact that they are used as staples also due to low production from non-implementation of agricultural mechanization. This unavailability leads to instability of price. 2.Adaptability Some of our local raw materials have been found to lack the required quality specification, especially due to genetic variation which is not suitable for large scale farming. 3.Technology Most of the existing technology are designed for a particular raw material and may not work well for another raw material. Prospects 1. Nigeria has high agricultural potential in terms of large expanse of land and fertile soil. 2. Economic recession could re-orientate our taste difference and many products which otherwise would not be acceptable can become acceptable e.g. chocolate drink versus zobo or kunnuzaki. 3. Lots of small scale food industries are springing up in order to reduce dependency on the large scale industry. 4. There are increases in research activities and participation of multi-nationals in expanding our raw material base e.g. CRIN and FIIRO. LIMITATIONS AND CONSTRAINTS OF LOCAL EQUIPMENT FOR FOOD INDUSTRIES 1.The finishing of most of the locally manufactured equipment is/are of low quality, as a high percentage of fabrications depend on the untrained/uneducated fabricators. 2.The range of equipment revolves round already known technologies. 3.The prevalent unit cost of equipment although cheaper than imported ones, is still too high with a resultant effect that only few can afford to buy them. 4.The ‘me too’ copy technological development characteristics of Japan and Asian countries is bound to be greatly hampered in Nigeria with the nonavailability or limited number of founding facilities and petrochemical products necessary for food processing and packaging equipment. 5. Stainless steel and Aluminum which are required for building food contacting component of machines are not produced locally but imported. 6. With the increasing rate of foreign exchange, the final market price of machine built from imported raw materials are bound to be exorbitant. 7.Absence of pilot plant stage, where the developed equipment could be evaluated for technical economic and operational feasibility under real condition, make many attempts aimed at equipment development a mere academic exercise. Recommendations for Improvements 1. The government should make a deliberate actions for solution. 2. A forum should be set up, where RMRDC, FIIRO, PRODA and fabricators that are keenly interested in the promotion of indigenous design and fabrication of food processing equipment, could meet, discuss and chart a course for way forward. 3. There should be an annual exhibition of food processing equipment and periodic “train-thetrainer” workshop for fabricators. 4. Government should make it mandatory for NERFUND to sponsor multiplication and commercialization of developed and proven prototypes of food processing equipment instead of funding mere importation of machinery from foreign industries. 5. Government through subvention obtained from food and pharmaceutical industry should set up at least one integrated processing and biomass utilization demonstration centre per state where this developed equipment could be constantly run for the public to see. 6.The development and utilization of food processing equipment should be directed to our rural areas where perishable raw materials are particularly abundant. ASSIGNMENT 1. Mention the Agricultural raw materials that are peculiar to each state in Nigeria. 2. Highlight the Roles of Government sourcing for food industrial raw materials. in 3. Using a bakery industry as a case study, write out the detailed quality specifications required for each raw materials used for bread baking.