Learning to be green: Involving students in the decision making

Learning to be green:

Involving students in the decision making process

Rich Gurney

Department of Chemistry

Simmons College

Boston, MA 02115 gurney@simmons.edu

Success is a journey, not a destination.

The doing is often more important than the outcome. - Arthur Ashe

Four stages of greening a process

choices:

– of the reaction

– in performing the reaction

– in isolating and purifying the product

– in characterizing the outcome of the reaction

Four stages of greening a process

choices:

– of the reaction

– in performing the reaction

– in isolating and purifying the product

– in characterizing the outcome of the reaction

[Oxidation]

OH

H

O

When choosing a synthetic path, consider...

• Applicability

• Selectivity

• Effectiveness

• % Yield

• Time

• $$

• Safety

• Hazards

• Disposal

• Energy

• Solvents

[Oxidation]

H

OH

Route 1: Na

2

Cr

2

O

7

/ H

2

SO

4

Route 2: NaOCl / HOAc

Hazards of oxidants:

Na

2

Cr

2

O

7

- Cr (VI)

- Highly carcinogenic (inhalation)

- Target kidney, liver, respiratory system, eye skin.

- Poison

NaOCl

- Organochlorine formation

- contains traces Hg

O

Pavia, D. L.; Lampman, G. M.; Kriz, G. S.; Engel, R. G. Introduction to Organic Laboratory

Techniques, a Small Scale Approach ; Third Edition; Saunders College Publishing: Fort Worth, TX, 1999.

How can we improve the process?

Twelve Principles of Green Chemistry

3. Process should use or generate little or no toxic materials.

5. Auxiliary substances should be eliminated whenever possible

(solvents, separating agents) or be innocuous.

6. Energy requirements should be minimized.

• Solvent (#5)

• Heterogeneous/Homogeneous (#3 & #5)

• Microwave heat (#6)

• Speed (#6)

How can we improve the process?

QuickT i me™ and a

T IFF (Unc ompres s ed) dec ompres s or are needed t o s ee thi s pi c ture.

(0 - 1)

QuickT i me™ and a

T IFF (Unc ompres s ed) dec ompres s or are needed t o s ee thi s pi c ture.

(2 - 3)

QuickT i me™ and a

T IFF (Unc ompres s ed) dec ompres s or are needed t o s ee thi s pi c ture.

(4 - 5)

Oxidant Water soluble, ground water contaminant, not catalytic, highly toxic or extreme hazard

Heterogeneous, not catalytic, moderate hazard

Heterogeneous, catalytic, mild or no hazard

Solvent Toxic, flammable Less toxic, not flammable

No solvent or benign solvent

Energy Hot plate: long heating time. Heat penetrates one area, danger of overheating.

Hot plate: shorter heating times, less energy expended.

Microwave energy: short heating time.

Or No heat is applied.

Time > 3 hours

Due to the constraints of lab period.

< 2 hours < 1 hr

[Oxidation]

OH

Standard Method:

Sodium dichromate (Na

Reaction Oxidant

Solvent During

Reaction

Energy Temp

Time Lab Time

H

2

Cr

2

O

>1 hr

7

)

Dichromate

Ether

Workup CH

2

Cl

2

/

Bicarbonate

Ice-Cold

0

0

1

3

3

7

O

Standard Method:

Bleach (NaOCl)

Bleach

Traces Hg

Acetone

CH

2

Cl

2

/ bicarbonate

50 min, 50 o C

> 1.5 hours

1

1

1

2

3

8 http://www.atsdr.cdc.gov/toxprofiles/phs7.html

“small amounts of chromium(VI) that you swallow will not hurt you; however, accidental or intentional swallowing of larger amounts has caused stomach upsets and ulcers, convulsions, kidney and liver damage, and even death.”

Solvent-Free, Microwave, Oxidation Reactions

Dr. Rajender Varma, U.S. EPA

• Clayfen

• Clay-cop Hydrogen Peroxide

• Chromium Trioxide impregnated on wet Alumina

• Iodobenzene Diacetate on Alumina

• Activated Manganese Dioxide on Silica Gel

[Oxidation]

H

OH

Reaction Oxidant MnO

2

- SiO

2

Solvent-Free Solvent During

Reaction

Workup

Energy Temp

Time Lab Time

Ether /

CH

2

Cl

2

Microwave

~ 2 hours

3

5

0

O

1

1

OX

2

QuickTime™ and a

TIFF (Uncompressed) decompressor are needed to see this picture.

5

2 15 http://www.atsdr.cdc.gov/toxprofiles/phs151.html

Manganese is a regular part of the human body; it is a necessary component in order for the body to work properly. The body normally controls the amount of absorbed manganese. For example, if large amounts of manganese are eaten in the diet, the body excretes large amounts in the feces. Therefore, the total amount of manganese in the body tends to stay about the same, even when exposure rates are higher or lower than usual.

Fall 2003:

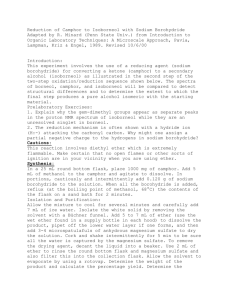

EXPERIMENTAL PROCEDURE:

H

[Oxidation]

MnO

2

- SiO

2

OH

Grind active MnO

2

, silica gel, and borneol in a mortar and pestle, until a homogenous mixture is obtained. Transfer this sample into a capped glass

O scintillation vial.

Place in the center of a household ($65) microwave.

Microwave at maximum intensity for 100 s. Remove the hot vial carefully.

Follow the reaction, by TLC (CH

2

Cl

2

) of a 1 mL diethyl ether extract of a spatula of the reaction material.

Repeat the microwave heating as necessary.

Once the reaction is complete by TLC and the reaction material is cooled to room temperature add 5 mL of CH

2

Cl

2

.

Separate the organic layer by vacuum filtration and remove the solvent to obtain crude product. Redissolve crude product in a minimum amount of diethyl ether to transfer to a sublimation chamber. Sublime product.

Characterize final product by TLC (CH

2

Cl

2

).

Four stages of greening a process

choices:

– of the reaction

– in performing the reaction

– in isolating and purifying the product

– in characterizing the outcome of the reaction

Fall 2003:

Can we find a better TLC solvent system to replace CH

2

Cl

2

?

+ (10:1, hexane:EtOAc) works perfectly.

Can the Et

2

O for TLC extract be replaced with a better solvent?

– hexanes - NO, EtOAc - no, EtOH - no, iPrOH - no.

Can we eliminate the final extraction solvent (CH

2

Cl

2

/ Et

2

O)?

+ place the glass vial in a heated sand bath, product camphor sublimes directly from the reaction mixture

– product collects in the cap.

– introduction of new heat source, hot plate / sand bath.

Can a test-tube replace the glass vial for final sublimation?

+ camphor sublimes toward the top of the tube, easier to collect

– product falls back onto the reaction materials.

How long is too long? Can we heat the reaction for a longer period and obviate the need to follow the reaction?

+ 20 sec, 40 sec, 60 sec, 120 sec, camphor to borneol ratio increasing.

– brown/white film climbing the side of the glass vial, top most rim of vessel

– white crystals form.

+ white crystals are product!

– microwave oven can overheat.

Fall 2003:

Can we eliminate the separate sublimation step and thereby eliminate the energy required for heating the sand?

+ upon further heating in the microwave, the camphor sublimes directly in the reaction vessel from the reaction mixture.

– yield low due to difficulty in isolating the product from the glass vial.

Can a corked test-tube replace the glass vial?

+ camphor sublimes toward the top of the tube, easier to collect

– product falls back onto the reaction materials.

Can a Petri-Dish replace the corked test-tube?

+ camphor sublimes on top dish, which is easily removed from the bottom, and product isolation is greatly facilitated.

How green is the characterization of the final product? Is TLC the best method of analysis?

+ IR Spectroscopy can be used to easily distinguish borneol from camphor,

– the final product is often contaminated with traces of water, which can be misinterpreted as an alcohol.

Fall 2003:

EXPERIMENTAL PROCEDURE:

[Oxidation]

MnO

2

- SiO

2

OH

H

Grind active MnO

2

, silica gel, and borneol in a mortar and pestle, until a homogenous mixture is obtained. Transfer this sample into a capped glass scintillation vial the bottom of a Petri-dish.

O

Replace Petri dish cover and place in the center of a microwave.

Microwave at maximum intensity for 100 s. Remove the hot dish carefully.

Follow the reaction, by TLC (CH

2

Cl

2

) of a 1 mL diethyl ether extract of a spatula of the reaction material. Repeat the microwave heating as necessary.

Once the reaction is complete by TLC and the reaction material is cooled to room temperature add 5 mL of CH

2

Cl

2

. Separate the organic layer by vacuum filtration and remove the solvent to obtain crude product. Redissolve crude product in a minimum amount of diethyl ether to transfer to a sublimation chamber.

Sublime product.

Recover the sublimed camphor from the Petri-dish cover with a razor blade.

Characterize final product by TLC (CH

2

Cl

2

).

Characterize final product by IR

Spectroscopy.

OH

H

[Oxidation]

MnO

2

- SiO

2

Reaction Oxidant MnO

2

- SiO

2

Solvent During

Reaction

Workup

Solvent-Free

Energy Temp

Time Lab Time

Ether /

CH

2

Cl

2

Microwave

~ 2 hours

0

5

2

3

5

1

1

OX

2

15

O

QuickTime™ and a

TIFF (Uncompressed) decompressor are needed to see this picture.

OH

H

[Oxidation]

MnO

2

- SiO

2

Reaction Oxidant MnO

2

- SiO

2

Solvent During

Reaction

Solvent-Free

Isolation

Purification

Solvent-Free

Energy Temp

Time Lab Time

Microwave

5 mins

5

5

5

3

5

1

1

OX

2

23

O

QuickTime™ and a

TIFF (Uncompressed) decompressor are needed to see this picture.

Fall 2004:

EXPERIMENTAL PROCEDURE:

Grind active MnO

2

, silica gel, and borneol in a mortar and pestle, until a homogenous mixture is obtained.

Transfer this sample into the bottom of a Petri-dish. Replace Petri-Dish cover and place in the center of a microwave. Microwave at maximum intensity for 100 s. Remove the hot dish carefully.

Recover the sublimed camphor from the Petri-dish cover with a razor blade.

Characterize final product by IR Spectroscopy.

Fall 2004:

Can we prevent the microwave from overheating?

+ a beaker of water absorbs excess energy in the microwave.

– but increases the -OH stretch in the IR spectrum of the product.

Can we prevent the microwave from overheating?

+ a beaker of alumina absorbs excess energy and does not increase the water content in the camphor product.

Can we diminish the water signal in the IR of the camphor product?

+ drying the silica gel and the MnO

2 product.

before use decreases water in the camphor

Can we maximize the yield of camphor by placing an ice cold Erlenmeyer on top of the

Petri-dish cover?

– ice cold Erlenmeyer does not appear to increase % yield, but increases the

–

OH stretch in the IR spectrum of the product.

Can we maximize the yield of camphor by using a Petri-dish with a smaller thickness to decrease the distance between the reaction medium and the product collection vessel?

– decreasing the distance increases the amount of MnO

2 sublimed camphor product.

that is “carried-up” with the

Can we increase the purity of the sublimed camphor by increasing the distance between the reaction medium and the product collection vessel?

+ increasing the distance decreases the amount of MnO

2

+ appears to increase the yield.

in the product

Fall 2004:

Can we decrease the amount of MnO

2 that is “carried-up” with the sublimed camphor product, by adding a thin layer of pure silica gel over the reaction medium?

+ sublimed material slightly cleaner,

– yield decreases.

Can we minimize the amount of MnO

2 that is “carried-up” with the sublimed camphor product, by increasing the particle size? Can we simply shake the reagents together instead of grinding them?

– the sublimed material is predominantly borneol instead of camphor when the reagents are shaken together instead of ground.

Can we create a semi-continuous reaction vessel by layering the MnO

2 borneol?

-silica over the

– no camphor is isolated.

Can the same reaction be used for the conversion of other alcohols?

+ norborneol can be converted to norcamphor

Does freshly prepared MnO

2

“work better” than “store bought” MnO

2

?

–

MnO

2 from Aldrich behaves identically to freshly prepared MnO

2

Can we increase the yield of camphor by spreading out the reaction medium on the bottom Petri-dish?

yield improves, yield decreases, yield remained the same?

Can we increase the yield of camphor by piling the reaction medium in the center of the

Petri-dish?

yield improves, yield decreases, yield remained the same?

Fall 2004:

Is the reaction stoichiometric or catalytic?

If the reaction is catalytic, can the reaction medium be used again to produce more camphor if more borneol is added?

If the reaction is catalytic, can the catalyst be regenerated?

If the reaction is catalytic, how many times can the reaction medium be reused?

What is the optimal heating time to produce camphor, while minimizing the sublimation of the starting borneol?

Does the particle size of the silica gel matter?

Can the reaction product ratio be followed by GC/MS?

Can the reaction product ratio be determined by 1H NMR?

“Why can’t we cancel the rest of the semester and continue working on this experiment?”

“Why haven’t we been introduced to green chemistry earlier?”

“Why isn’t every lab a green chemistry lab?”

“Who in their right mind thinks that green chemistry is a bad idea?”

“Why is this (Green Chemistry) a separate concept from regular Chemistry?”

Fall 2005:

+A beaker of dry ice atop the Petri Dishes, increases condensation of product by cooling the surface without addition of water.

+Reaction is not catalytic.

+Used manganese dioxide silica mixture, can not be reused.

+Many different reactor designs can be used effectively.

+The particle size of the silica gel does not cause a statistically significant increase in yield or purity of camphor.

+The reaction product ratio can be followed by GC/MS using a standard

GowMac GC using temperature settings typically suited for the separation of cyclohexane and toluene.

+The presence of borneol in the camphor product down to a 5% can be observed by 1H NMR (90 MHz, EFT Anasazi).

+The yield of camphor can increase from 12 - 15% to 85 - 92% while still maintaining a 90 - 95% purity level by heating the reactor directly on a hotplate, by carefully monitoring the temperature.

(Best temperature “program”: 25 o C to 165 o C over ~5 min.; hold at 165 o C for

10 min.; ramp up to 200 o C over 5 min. and hold at 200 o C for 10 min.).

+Better reactor can be designed for hotplate reaction.

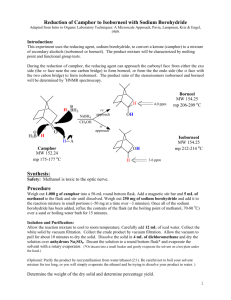

Alternative “Jetsons’” Probe

By: Tayaba Naz

4” Watch Glass

1” Watch Glass

Wide-mouth Powder Glass Funnel

Hotplate

0.350g MnO

2

0.70g Silica Gel

0.40g Borneol

Step 1: Weigh the small watch glass and the funnel.

Step 2: Mix the reagents in a small 50-mL beaker with a metal spatula for 5 minutes and pour the regents in a pile on the large watch glass.

Step 3: Cover the reagents with the cut-off or wide-mouth powder funnel as shown in the figure above. Place the small watch glass on the mouth of the funnel.

Step 4: Carefully put the setup on the hotplate and gradually raise the temperature of the hotplate to 165 o C over ~5 minutes. Monitor the temperature with a thermocouple.

Step 5: Hold the temperature of the hotplate at 165 o C for 10 minutes.

Step 6: Gradually raise the temperature of the hotplate to 200 o C over ~5 minutes and hold the temperature of the hotplate at 200 o C for 10 minutes.

Step 7: Carefully remove the setup from the hotplate and allow it to cool for about 5 minutes.

Ensure the temperature is below 45 o C

Step 8: Weigh the funnel and the small watch glass with the sublimed camphor product and determine the isolated weight and percent yield of your product.

Step 9: Run TLC/IR/NMR/GC on your product to check the purity.

Key Concepts introduced: solid-phase green oxidation

• Synthesis: Solid phase oxidation chemistry

• Work-up techniques: heterogeneous extraction

• Purification techniques: sublimation

• Characterization methods:

• sealed capillary tube melting point determination

• thin layer chromatography (ethyl acetate/hexanes)

Value Added: solid-phase green oxidation

Added Characterization methods due to extra time:

• 1H NMR (CDCl

3

)

• GC (traces of diethyl ether)

• IR (KBr)

Contextualized discussion of:

• heterogeneous reactions

• solvent free reactions

• MSDS, safety, disposal, environmental consequences

• alternative energy sources (reaction can be done in microwave)

• choosing from multiple synthetic procedures

Spare lab time to allow students to apply and test green chemical principles

Unanticipated outcomes: solid-phase green oxidation

• high level of student engagement with content

• high level of student personal accountability

• engagement within research and scientific method

• increased enthusiasm for chemistry and chemical research

• true concern and appreciate for disposal and safety

• every student became a critical evaluator

• every student became a contributing member of my research group

“We don’t receive wisdom, we must discover it ourselves after a journey that no one can take for us, or spare us.” Marcer Proust

“Who would venture upon the journey of life, if compelled to begin it at the end.” Madame de Maintenon.

“Am I going to be an author on the paper?” Brandi Watts, Simmons ‘05

“Maybe I should consider a career in chemical research instead of medical school because I can bring about greater good, by championing green chemistry.” Tayaba Naz ‘08

QuickTime™ and a

TIFF (Uncomp resse d) de com press or are nee ded to s ee this picture.

Acknowledgements

Tayaba Naz, Simmons College (‘08)

Shauna Tracy, Simmons College (‘08)

YinYin Lin, Simmons College (‘05)

Craig Schwartz, Northwestern University (‘04) (UC Berkeley)

Marc Sala, Northwestern University (‘04) (Northwestern Medical)

Students in CHEM 225, Fall 2003, 2004, 2005

Henry and Camille Dreyfus Foundation Postdoctoral Fellowship in Environmental

Chemistry

Simmons College Faculty Start-Up Funds.

Procedures? Slides? Technical help? Questions? Contact me:

Rich Gurney

Department of Chemistry

Simmons College

Boston, MA 02115 gurney@simmons.edu

(617) 521 - 2729

QuickTime™ and a

Sorenson Video 3 decompressor are needed to see this picture.

Procedures? Slides? Technical help? Questions? Contact me:

Rich Gurney

Department of Chemistry

Simmons College

Boston, MA 02115 gurney@simmons.edu

(617) 521 - 2729