unit4 - CLSU Open University

advertisement

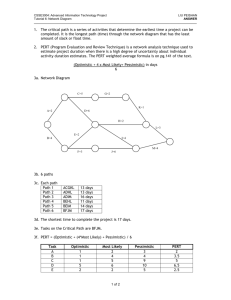

UNIT IV PROGRAM EVALUATION AND REVIEW TECHNIQUE (PERT) AND CRITICAL PATH METHOD (CPM) Introduction Many managerial problems in areas such as transportation systems design, information systems design and project scheduling have been successfully solved with the aid of network models and network analysis techniques. The techniques to be introduced here have been applied successfully to a wide range of significant management problems. The Polaris missile project was planned with the aid of PERT (program evaluation and review technique), which we shall study in this unit. CPM (critical path method) was successfully used by one of the authors to plan and coordinate the activities of two governments as they cooperated in an earthquake relief project in Turkey. Other uses of network models include planning the flow of traffic to minimize congestion in cities, determining the shortest pickup and delivery routes for package-handling companies and even finding the best layout for the water system in a new residential subdivision. Course Objectives To introduce students to the basic principles behind network models To give students an overview of two of the most important network models: Program Evaluation and Review Technique (PERT) and Critical Path Method (CPM) To demonstrate, using illustrative examples, how PERT can be applied to a business problem Suggested Timeframe 6 hours The Framework of PERT and CPM Program Evaluation and Review Technique (PERT) and the Critical Path Method (CPM) are two popular quantitative techniques that help managers plan, schedule, monitor, and control large, complex and a wide variety of projects, such as: 1. Research and development of new products and processes 2. Construction of plants, buildings and highways 3. Maintenance of large and complex equipment 4. Design and installation of new systems There are six steps common to PERT and CPM, and these are: Define the project and all of its significant activities and tasks. Develop the relationships among the activities. Decide which activities must precede and follow others. Draw the network connecting all of the activities. Assign time and/or cost estimates to each activity. Compute the longest time path through the network. This is called the critical path. Use the network to help plan, schedule, monitor, and control the project. Finding the critical path is a major part of controlling a project. The activities on the critical path represent tasks that will jeopardize the entire project if they are delayed. Managers derive flexibility by identifying noncritical activities and replanning, rescheduling and reallocating resources such as manpower and funds. Main Difference Between PERT and CPM PERT and CPM essentially follow the same procedure when applied; however, PERT is a probabilistic technique, whereas CPM is a deterministic one. PERT incorporates statistical concepts in the calculation of activity time. It was developed with an objective of being able to handle uncertainties in activity completion times. On the other hand, CPM was developed primarily for scheduling and controlling industrial projects where job or activity times were considered known. CPM offered the option of reducing activity times by adding more workers and/or resources, usually at an increased cost. It simply assumes normal times in the determination of the critical path. Program Evaluation And Review Technique (PERT) PERT was developed in the 1950s by the Navy Special Projects Office in cooperation with Booz, Allen and Hamilton, a management-consulting firm. It was specifically directed at planning and controlling the Polaris missile program, a massive project which had 250 prime contractors and over 9000 subcontractors. Imagine the problems faced by the project director in attempting to keep track of hundreds of thousands of individual tasks on this project. The introduction of PERT into the Polaris project helped management answer questions like these: When will the project be finished? When is each individual part of the project scheduled to start and be finished? Of the hundreds of thousands of “parts” of the project, which ones must be finished on time to avoid being late? Is it possible to shift resources to critical parts of the project (those that must be finished on time) from other noncritical parts of the project (parts which can be delayed) without affecting the overall completion time of the project? Among all the hundreds of thousands of parts of the project, where should management concentrate its effort at any one time? (Levin et.al. 1982) Other Network Techniques Aside from PERT and CPM, there are numerous other network models useful for business decision making. Three of these are listed below: Minimal-Spanning Tree Technique. This technique determines the path through the network that connects all the points while minimizing total distance. Maximal-Flow Technique. This technique finds the maximum flow of any quantity or substance through a network. Shortest-Route Technique. This technique finds the shortest path through a network. EXAMPLE: The Maginhawa Company has manufactured industrial vacuum cleaning systems for a number of years. Recently its new research team submitted a report suggesting the company consider manufacturing a cordless vacuum cleaner that could be powered by a rechargeable battery. The vacuum cleaner, referred to as Maginhawa-Vacuum, could be used for light industrial cleaning and could contribute to the company’s expansion into the household market. Management hoped that the new product could be manufactured at a reasonable cost and that its portability and no cord convenience would make it extremely attractive. Maginhawa Company’s top management would like to initiate a project to study the feasibility of proceeding with the Maginhawa-Vacuum idea. The data are shown in Table 1. Table 1. Activity list for the Maginhawa -Vacuum Project Activity Description A R & D product design B Plan market research C Routing (manufacturing engineering) D Build prototype model E Prepare marketing brochure F Cost estimates (industrial engineering) G Preliminary product testing H Market survey I Pricing and forecast report J Final report Immediate Predecessors A A A C D B, E H F,G,I The network for the Maginhawa-Vacuum project is shown in Figure 1. Routing C 2 5 Product Design A 1 Cost Estimates F Prototype D Marketing Brochure E 4 Testing G 7 Final Report J 8 Completion Market Research Plan B Market Survey H 3 Pricing and Forecast I 6 Activity Times The next step in the PERT procedure is the assignment of estimated time required to complete each activity. Time is usually given in units of days or weeks. PERT uses a probability distribution based on three time estimates for each activity. These are: Optimistic Time (a). The activity time if everything goes as well as possible. Most Probable Time (m). Most realistic time estimate to complete the activity. Pessimistic Time (b). The activity time if we encounter significant breakdowns and/or delays PERT assumes that the time estimates follow the beta probability distribution Probability a m b Activity Time As an illustration of the PERT procedure with uncertain activity times, let us consider the optimistic, most probable and pessimistic time estimates for the Maginhawa-Vacuum activities as presented in Table 2. Table 2. Optimistic, most probable and pessimistic time estimates (in weeks) for the MaginhawaVacuum project Activity Optimistic (a) 4 1 2 3 2 1.5 1.5 2.5 1.5 1 A B C D E F G H I J Most Probable (m) 5 1.5 3 4 3 2 3 3.5 2 2 Pessimistic (b) 12 5 4 11 4 2.5 4.5 7.5 2.5 3 To find the expected time (t) for an activity, the beta distribution weights the estimates as follows: a + 4m + b t= 6 Finding the Critical Path To find the critical path, we need to determine the following quantities for each activity in the network: Earliest Start Time (ES). This is the earliest time an activity can begin without violating any of the immediate predecessor requirements. Earliest Finish Time (EF). This is the earliest time an activity can end. Latest Start Time (LS). This is the latest time an activity can begin without delaying the entire project. Latest Finish Time (LF). This is the latest time an activity can end without delaying the entire project. Computing ES and EF Begin at the network’s origin. For the first event, the starting time is always set to zero (0). EF = ES + T ES time rule: Before any activity can be started, all of its predecessor activities must be completed, that is, search for the longest path to an activity in determining ES. Computing LS and LF Begin at the network’s end. Make a backward pass through the network. LS = LF – T The latest time for an activity equals the smallest LS for all activities leaving that event. Computing Slack Times After constructing the network and determining the critical path, slack times may be calculated in one of two ways: Slack = LS – ES or Slack = LF – EF Variability in the Project Completion Date To compute the dispersion or variance of T: b - a 2 Variance of activity time = 6 Table 3. Expected times and variances for the Maginhawa-Vacuum activities Activity Expected Time (t) Variance (in weeks) A 6 1.78 B 2 0.44 C 3 0.11 D 5 1.78 E 3 0.11 F 2 0.03 G 3 0.25 H 4 0.69 I 2 0.03 J 2 0.11 Total 32 The total expected time to complete the work for the Maginhawa-Vacuum project is 32 weeks. It can be seen also from the network that several of the activities can be conducted simultaneously (A and B for example). Being able to work on two or more activities simultaneously will have the effect of making the total project completion time shorter than 32 weeks. In order to arrive at a project duration estimate, we will have to analyze the network and determine what is called the critical path. A path is a sequence of connected activities that leads from the starting node (1) to the completion node (8). The connected activities defined by nodes 1-2-5-7-8 form a path consisting of activities A, C, F, and J. The longest path determines the expected total time or expected duration of the project. If activities on the longest path are delayed, the entire project will be delayed. Thus the longest path activities are the critical activities of the project and the longest path is called the critical path of the network. C 2 5 3 A 5 6 1 D F 2 J G 3 E 4 7 3 2 8 B 2 I 2 H 3 6 4 Figure 2. Maginhawa-Vacuum Proj.Network with Expected Activity Times Table 4. Activity schedule (in weeks) for the Maginhawa-Vacuum project Activity A B C D E F G H I J Earliest Start 0 0 6 6 6 9 11 9 13 15 Latest Start 0 7 10 7 6 13 12 9 13 15 Earliest Finish 6 2 9 11 9 11 14 13 15 17 Latest Finish 6 9 13 12 9 15 15 13 15 17 Slack (LS-ES) 0 7 4 1 0 4 1 0 0 0 Critical Path? Yes Yes Yes Yes Yes The variance in the project duration is given by the sum of the variance of the critical path activities. Thus the variance for the Maginhawa-Vacuum project completion time is given by σ 2 = σ 2 A + σ 2 E+ σ 2 H + σ 2 I + σ 2 J = 1.78 + 0.11 + 0.69 + 0.03 + 0.11 = 2.72 Since we know that the standard deviation is the square root of the variance, we can compute the standard deviation σ for the Maginhawa-Vacuum project completion time as follows: 2 2.72 1.65 A final assumption of PERT is that the distribution of the project completion time T follows a normal or bell-shaped distribution. With this, we can compute the probability of meeting a specified project completion date. For example, suppose that management has allotted 20 weeks for the Maginhawa-Vacuum project. While we expect completion in 17 weeks, what is the probability that we will meet the 20-week deadline? The z value for the normal distribution at T = 20 is given by Z = 20 – 17 = 1.82 1.65 1.65 Weeks Expected Completion Time T 17 Time (Weeks) Figure 3. PERT Normal Distribution of the Project Completion Time Variation for the Maginhawa-Vacuum Project Using z = 1.82 and the tables for the normal distribution, we see that the probability of the project meeting the 20-week deadline is 0.4656 + 0.5000 = 0.9656. Thus while activity time variability may cause the project to exceed the 17-week expected duration, there is an excellent chance (96.56%) that the project will be completed before the 20-week deadline. YOUR ACTIVITY I. Electrika is a company that installs wiring and electrical fixtures in residential construction. Its general manager has been very concerned with the amount of time it takes to complete wiring jobs. Some of his workers are very unreliable. A list of activities and their optimistic completion time, the pessimistic completion time, and the most likely completion time is given in the following table. Activity A B C D E F G H I J K a 3 2 1 6 2 6 1 3 10 14 2 m 6 4 2 7 4 10 2 6 11 16 8 b 8 4 3 8 6 14 4 9 12 20 10 Immediate Predecessors None None None C B,D A,E A,E F G C H,I a. Draw the appropriate PERT network. b. Determine the expected completion time and the variance for each activity. c. What is the critical path? II. Activity A B C D E F G H Assume that the project has to be completed in 16 weeks. Crashing of the project is necessary. Relevant information is shown. Immediate predecessor A B,C D E B, C F, G Normal time (wks) 3 6 2 5 4 3 9 3 Crash time (wks) 1 3 1 3 3 1 4 2 Normal cost (P) 900 2000 500 1800 1500 3500 8000 1000 Crash cost (P) 1900 4000 1000 2400 1850 3900 10000 2000 a. Make the minimum cost crashing decisions. What is the added cost of meeting the 16week completion time? b. Develop a complete activity schedule using the crashed activity times. REFERENCES Andersen, D.R., D.J. Sweeney, & T.A. Williams, An Introduction to Management Science: Quantitative Approaches to Decision Making Andersen, D. R., Dennis J. Sweeny, and Thomas A. Williams. 2001. Quantitative Methods for Business. Eighth edition. Cincinnati, Ohio: South-Western College Publishing. Anderson, Michael Q. 1982. Quantitative Management Decision Making, Belmont, California: Brooks/ Cole Publishing Co., Dunn, Robert A. and K. D. Ramsing. 1981. Management Science: A Practical Approach to Decision Making. New York, New York: MacMillan Publishing Co., Engbino, Diosdado. Management Decision Models: An Overview. Given as a reference material in the Quantitative Methods for Business class in 1987. Krajewski, Lee C. and H. E. Thompson. 1981. Management Science: Quantitative Methods in Context, New York: John Wiley & Sons, Levin, R.I.., C.A. Kirkpatrich & D.S. Rubin. 1982. Quantitative Management. 5th ed. McGraw-Hill, Inc. Approaches to Zamora, Elvira A. 2004. Basic Quantitative Methods for Business Decisions. UP College of Business Administration.