PERT/CPM Project Scheduling: Critical Path Method Explained

advertisement

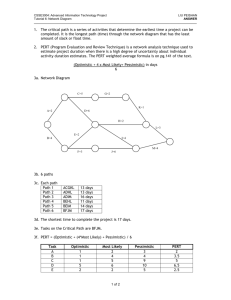

PERT/CPM PROJECT SCHEDULING • Allocation of resources. • Includes assigning the starting and completion dates to each part (or activity) in such a manner that the whole work (or project) proceeds in a logical sequence and in an orderly and systematic manner. OBJECTIVES OF SCHEDULING • • • • • To minimize cost of production and storage. To maintain minimum cash outflow. Maximum/effective utilization of resources. Maximum plant utilization. To ensure maximum customer satisfaction. PERT • Program Evaluation and review technique • Time-event network analysis in which the various events in a program or project are identified, with a planned time established for each. • These events are placed in a network showing the relationships of each event to the other events. 102 9 2 17 56 4 17 8 10 12 36 1 3 10 40 7 8 10 13 9 12 41 10 6 11 19 52 5 12 PERT • Each circle represents an event. • Circles are numbered in the order in which the events occur. • Each arrow represents an activity- the time consuming element of a program. • Activity time represented by the number between the arrows, is the time required to accomplish an event. PERT • In this example, only a single time is shown for each activity, but in the original PERT program there were three “time estimates”. • Optimistic time: an estimate of the time required if everything goes extremely well. • Most likely time: an estimate based on the time the project engineer really believes is necessary for the job • Pessimistic time: a time based on the assumption that some logically conceivable bad luck, other than a major disaster, will be encountered. • These estimates are often included in PERT because it is very difficult, in many engineering and development projects to estimate time accurately. ADVANTAGES OF PERT • Forces managers to plan because it is impossible to make a time-event analysis without planning and seeing how the pieces fit together. • Forces planning all the way down the line because each subordinate manager must plan the event for which he or she is responsible. • Concentrates attention on critical elements that may need correction. • Enables managers to prepare reports. LIMITATIONS OF PERT • Emphasis on time not costs. • Not useful when estimates of time cannot be made. 9 2 4 1 3 8 7 6 5 10 13 11 12 CRITICAL PATH METHOD • Sequence of events that take the longest time and that has zero(or the least ) slack time. • Critical path comprises events 1-3-4-8-9-13. • Over this path, the activity time for this sequence of events is 131.6 weeks. • If promised delivery is in 135 weeks, even this critical path will have been completed 3.4 weeks ahead of time. CRITICAL PATH METHOD • Some of the other paths like 1-2-9-13 are almost as long as the critical path = 129 weeks • It is customary to identify several critical paths in order of importance. • Identifying the CP makes possible close monitoring of this particular sequence of events to ensure that the whole program is on schedule.