clearguard

advertisement

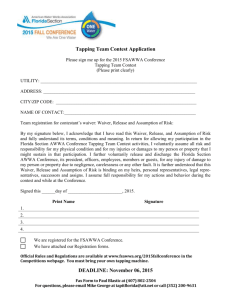

CLEARGUARD™ SOLVING THE AGE OLD INSTRUMENT TAPPING POINT PROBLEM. Measuring Process Variables accurately, using Pressure and Differential Pressure Transmitters, requires Clear Instrument Tapping Points. Partially Blocked or Completely Blocked Instrument Tapping Points induce errors, cause Unplanned Shutdowns, consume Substantial amounts of Purge Medium, give rise to Hazardous Maintenance Practices and Reduce Operator Confidence, Plant Efficiency and Productivity. An Australian Company, Clearguard Pty Ltd, have developed and successfully field-tested an Automatic Instrument Tapping Point Clearing Device that solves these problems. Based on the Simple and Proven Principle of Solving the Cause of the Problem, Clearguard Periodically and Automatically Clears any Instrument Tapping Point of Fresh Scale or Debris deposits. Most Pressure and Differential Pressure Transmitter Installations for Process Variable Measurements use an Inert Purge Medium for Accurate Process Variable Measurement, especially in applications where it is possible for slurry or sediment to enter the transmitter or it’s impulse tubing. The Purge Medium, be it Static or Flowing, is a barrier between the process and Field Instrument. In many Applications a substantial Purge Medium flow rate is used to delay Scale Build-up or Debris Accumulation in the Tapping Point. With a Clear Instrument Tapping Point, the unimpeded Purge Medium Flows through the Instrument Tapping Point allowing accurate Process Variable Measurement. As the Tapping Point starts to block it impedes the Purge Medium Flow and “Backpressure” is subsequently created. The DP Cell interprets this Backpressure as the Process Variable. Furthermore, the addition of Purge Medium Dilutes the Process, requiring total removal later in the Process Train. Clearguard substantially reduces the amount of any Flowing Purge Medium to an almost “Static Purge” situation. Many Process Plants employ the Hazardous Procedure of Manually “Rodding Out” Instrument Tapping Points whilst the unit is “On-Line”. This Procedure often requires the unit to be placed on “Bypass” or the Field Instrument to be temporarily “Off-line”. Clearguard totally eliminates the need for this procedure. The recent considerable growth in Complex Non-Contact Process Variable Measurement Devices has been partially fuelled by the problem of Partial and Complete Blocking up of Instrument Tapping Points. Devices such as Radar, Magnetic Flow Meters, Ultrasonic, Nucleonics, and Load Cells have been selected in those applications where Problematic Instrument Tapping Points have precluded the use of Differential Pressure Transmitters. Process Plants have been forced to specifically train personnel in Specialized Maintenance Procedures, additional resources to maximise the operation of these devices have been required, larger inventories and variety of Spare Parts have been needed and in many instances these complex devices do not prove as rugged, reliable and accurate as the proven Differential Pressure Transmitter. Clearguard restores the use of the Differential Pressure Transmitter in many Process Variable Measurement Applications. Process Plants will be able to reduce Field Instrument Inventories and employ proven technology. Rarely is there a device that can claim to be revolutionary. The ramifications of Clearguard are not limited to the following; SAFETY:- Tapping Points don’t need drilling. ESD systems don’t go on “bypass”. ACCURACY:- Tapping Points don’t induce unknown errors. RELIABILITY :- Measurements can be trusted. SIMPLICITY:- Complex Instruments are not needed. PLANT AVAILABILITY:- No shutdowns due to false measurements or to drill Tapping Points. PURGE CONSUMPTION Purge-Water can be almost static. PurgeAir are bubbles per minute. PURGEFLUID EXTRACTION Add less fluid, extract less fluid. MAINTENANCE EFFICIENCY More efficient use of highly trained maintenance personnel. PRODUCTION EFFICIENCY If you measure more accurately, you can control more accurately and produce more efficiently. SERVICEABILITY Clearguard is field replaceable and easily serviceable. STANDARDIZATION Maximise the use of reliable, accurate, cost effective and simpler primary elements. Process Plants which include a multitude of Tapping Points with high consumption rates of Purge Medium can, with the installation of Clearguard, immediately improve the efficiency of other Downstream Process Equipment. Process Pumps transport more Product and less Purge Medium. Confidence in Process Variable Measurement allow Operators to reduce “error margins”. Unplanned unit shutdowns due to Blocked Instrument Tapping Points no longer occur. Powered by a Pneumatic Linear Cylinder Actuator, a Custom Scraper, fixed to the Cylinder Rod is stroked in and out of a Tapping Point as a Process dictates. The Scraper is hollow and includes Holes to allow the Uninterrupted Flow of Purge Medium. Available in 3 major different configurations, Clearguard may be used in Pressure Applications to ANSI 900# and Temperatures to 280 °C. Standard Materials of Construction include Carbon Steel and 316 Stainless Steel, with alternate materials available upon request. Clearguard, whilst simple to install and maintain is application specific. Insertion Lengths vary from narrow Pipe or Vessel Walls up to 900mm. Clearguard is patent pending in Australia, USA and throughout the World. After 12 months of exhaustive field trials, Clearguard was released in March 2002. Principle of Operation: 3 2 IMPULSE TUBE 1 4 6 5 LTPR By switching instrument air between the pneumatic cylinder ports (2,3) the scraping tool (1) is cycled through the Instrument Tapping Point, removing any deposits of scale or debris. The scraping tool (1) is designed to allow the unrestricted flow of purge medium throughout the stroking process, ensuring no false readings are generated at the pressure / differential pressure sensor. The seal assembly (5) prevents the egress of process materials. On LTPR models the outboard shaft (4) is a visual position indicator. On the end of the outboard shaft is a pin (6) which, in the case of the Clearguard not fully retracting due to loss of air or power, can be engaged by a manual retracting tool. LTPS and HTP models use an internal connection for the manual retractor. Actuation of the Clearguard can be initiated manually or via a pneumatic or electronic timer.