The UK and the global car industry

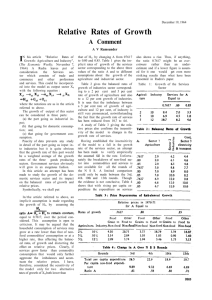

advertisement

The UK and the global car industry Car manufacture is a major global industry. Most MEDCs produce cars and a growing number of LEDCs (mostly NICs) have become car manufacturers in recent decades. In addition, more than 100 countries make parts and components. This is a globalised industry that is in a significant period of change. The major global car manufacturers Figure 1 shows the world’s top ten car manufacturers in 2003. All are large transnational corporations. The American giant General Motors (GM) heads the list with over 8.5 million vehicles sold. Ford and Daimler Chrysler add to the significant American presence in large-scale motor manufacture. Japan is represented by Toyota, Nissan and Honda; Germany by Volkswagan and Daimler; France by PSA/Peugeot Citroen; and South Korea by Hyundai. In terms of overall national production, Japan replaced the USA as the top car manufacturer between 1980 and 1983. It regained first place from the USA in 1987 and still holds that position today. Some industry experts expect Toyota to take over from GM as the world’s largest car producer before the end of the present decade. Figure 1. The World’s top ten car manufacturers in 2003. Global vehicle Sales Market cap $bn, units sold, m $bn latest General Motors 8.59 185.5 23.3 Toyota 6.78 153.1* 136.4 Ford 6.54 164.2 24.8 Volkswagen 5.02 98.4 12.2 DaimlerChrysler 4.36 171.9 41.8 PSA/Peugeot Citroen 3.29 61.2 14.3 Hyundai Automotive 3.05 38.9 9.0 Nissan 2.97 65.8* 47.1 Honda 2.91 77.2* 46.4 Renault 2.39 42.4 22.1 *Year ending March 2004 Source: The Economist, 4th September 2004. Britain is unrepresented in the top car league, but this was not always the case. In 1972, British Leyland was the third-biggest car firm in the world. However, it was not long before poor management and uncooperative unions brought about the demise of British-owned car manufacturing. MG Rover, the last British-owned car company, collapsed in April 2005. Although Toyoto is second to GM in terms of vehicles sold, its market capitation (stock market value) is by far the highest of all the major producers (Figure 1). The relatively strong stock market position of Japanese producers is because they are more profitable than their American counterparts. In 2003, Chrysler was losing $496 on every car it sold, compared with Ford’s $48. In contrast, GM made a profit of $178 per car. However, Japanese profits were far greater – Honda $1,488, Toyota $1,742, and Nissan $2,402. The large American manufacturers, particularly GM and Ford, have been going through a very difficult time recently. According to The Economist, ‘For the past two years the threat of collapse has hung in the Detroit air as American car firms have wrestled with falling sales, unprecedented competition at home and soaring retirement and health-care costs for current and former employees’. GM now has 2.5 pensioners for every current employee. Costs associated with retired employees are known as legacy costs. Figure 2 shows the effect legacy costs have had on profits in recent years. The company has reacted to increasing competition, and it now employs only 324,000 workers compared to 877,000 twenty years ago, having laid off workers, closed factories and outsourced parts supplies. Under similar circumstances, Ford closed five American factories between 2002 and 2005. In the cities affected by plant closures, a negative process of cumulative causation has often ensued as sacked workers have found it hard to find new jobs. Figure 2. The effect of legacy costs on profit margins. Year Profit margin % Profit margin without legacy costs % 1999 9 11 2000 8 10 2001 5 8 2002 7 10 2003 6 11 2004 6 10 2005 4 9 Source: The Economist 23/04/05, Article: Ford and General Motors: How much worse can it get? However, as Figure 3 shows, the original equipment manufacturers (Ford, Toyota etc.) are only one part of the automotive-industry value chain. Aftersales account for by far the largest share of annual profits when looking at the industry as a whole. Figure 3. Annual profits in the automotive-industry value chain in 2003. Area Percentage of pre-tax profits Aftersales 43 Retailers 5 Suppliers 28 Original equipment manufacturers 24 Total revenue $210 billion Source: The Economist 04/09/04. Car manufacturing is considered to be of strategic importance in many countries. However, with increasing maturity, it has stagnated in its core bases of the USA, Western Europe and Japan, with average profit margins down to below five per cent in 2004. This compares to twenty per cent or more in the 1920s and around ten per cent in the 1960s. Today, the car industry accounts for 0.6 per cent of stock market capitalisation in the USA and 1.6 per cent in Europe. Two decades ago the corresponding figures were 4.0 per cent and 3.6 per cent. In MEDCs, the car industry is viewed as a sunset or mature industry. Unlike Japan and Europe, the US car industry does not rely significantly on foreign exports. US car manufacturers focus predominantly on the domestic market and to some degree on the Canadian market. The ‘Big Three’ US car manufacturers have invested heavily in the Canadian market, which has resulted in Canada becoming a global leader in automotive engineering. Figure 4 shows how the geographical location of car production has changed since 1997, while Figure 5 shows the world regional breakdown of production for all motor vehicles. Figure 4. Passenger vehicle production since 1997 by region. 1997 1998 1999 2000 2001 2002 North America 8,122 8,027 8,256 8,372 7,155 7,346 South America 1,890 1,493 1,345 1,650 1,722 1,671 European Union 13,451 14,522 14,835 14,779 14,939 14,815 Other Europe 2,329 2,410 2,479 2,628 2,435 2,497 Japan 8,494 8,056 8,102 8,359 8,118 8,619 South Korea 2,133 1,625 2,362 2,602 2,471 2,651 Other Asia & Oceania 2,034 1,793 2,086 2,825 2,899 3,413 Total 38,453 37,926 39,465 41,215 39,739 41,012 Figures are in thousands. Source: OICA.net. Figure 5. All motor vehicle production since 1997 by region. 1997 1998 1999 2000 2001 2002 North America 16,017 16,009 17,603 17,697 15,626 16,724 South America 2,326 European Union 15,403 16,612 16,913 17,105 17,310 16,948 Other Europe 2,727 Japan 10,817 10,050 9,908 10,140 9,777 10,258 South Korea 2,818 1,954 2,843 3,115 2,947 3,147 Other Asia & Oceania 4,325 3,631 4,192 5,145 5,624 6,674 Total 1,893 2,839 1,651 2,902 2,087 3,085 2,114 2,850 2,000 2,951 54,433 52,988 56,012 58,374 56,248 58,702 Figures are in thousands. Source: OICA.net. Globally, the motor vehicle industry is a major resource user requiring: Nearly half the world’s annual production of rubber. Twenty-five per cent of global glass production. Fifteen per cent of annual steel production. The continuing process of consolidation The industry has been consolidating since the early part of the twentieth century. In the late 1920s, there were 270 car companies in the world, with most located in the USA. From these the global giants of GM, Ford and Chrysler emerged. Consolidation has tended to occur in phases, with the past decade witnessing significant activity. Today the global car industry is dominated by seven large groups and three smaller ones. The six groups of GM, Toyota, Ford, Renault/Nissan, Volkswagen and Daimler Chrysler account for about 70 per cent of global sales. Figure 6 shows the decline in the number of big independent manufacturers since 1980. Perhaps the most successful of the recent alliances has been between Renault and Nissan. In 1999, Renault took a 37 per cent stake in Nissan. The two companies decided to keep their separate identities to retain brand loyalty. The two companies are now pushing ahead with plans to share car platforms, aiming to reduce the number across the two companies from 40 in 2,000 to ten in 2010. This will open the way to common purchasing, which should save more than 500 million euros a year. Figure 6. Decline in number of big independent manufacturers With intense competition, factories have to be large to benefit from the biggest economies of scale. This means around 250,000 units a year for assembly plants and 1–2 million units for making body panels. Globalisation and market orientation The car industry is a good example of a market-oriented industry. The impetus to manufacture in major markets is due to a number of factors. Arguably the most important is that tastes or fashions in car size and design can vary significantly around the world. In a world where fashion can change very quickly indeed, manufacturers need to produce exactly what customers want if they are to make a profit. However, new markets for cars are also invariably lower-cost countries (for labour, land and other important cost factors), which make opening new plants an attractive proposition. In addition, other factors, such as getting around tariff barriers and reducing transport costs, also have an impact on location decisions. The globalisation of the car industry accelerated in the latter half of the 1990s due to: The construction of major overseas facilities, a process known in the industry as ‘global market dynamics’ (as explained in the previous paragraph). The establishment of mergers between major manufacturers. For example, the Chrysler Daimler-Benz merger was initiated by the European manufacturer in an attempt to strengthen its position in the US market. The considerable development of joint ventures between the global giants and smaller manufacturers in newly industrialised countries. An increasing number of cars are manufactured by joint ventures in China, India and other NICs. Governments in NICs see joint ventures as an important means by which their own domestic companies and their labour force can acquire expertise from major transnational corporations. For the latter, a joint venture may be the only initial way into an emerging market because the laws of the host country may not allow 100 per cent foreign ownership. The product lifecycle Figure 7 is very useful in understanding the product lifecycle in relation to the changing location of the car industry. The market has reached maturity in North America, Japan and Western Europe where car ownership is widespread and near saturation. In these markets, most car sales are to replace older vehicles that are being sold second-hand or scrapped by their owners. However, in LEDCs, particularly the NICs where incomes are rising rapidly, the scope for selling to first-time buyers is much greater. Developing countries can be placed in either the early or growth stages of the model. If the potential market in a developing country is very large, major manufacturers will be likely to locate there to take advantage of manufacturing in a growing market for cars and also to benefit from lower wages and other costs. Brazil, China and India are good examples of this process. China is already the world’s fourthlargest car market (after the USA, Japan and Germany), with sales of 2.3 million in 2004. Figure 7. The product lifecycle. Figure 8 illustrates the stages of development in the Brazilian car industry. Virtually every major car manufacturer has facilities in Brazil, the largest market in Latin America. The rapid growth of the middle class in Brazil has resulted in a considerable increase in the demand for new cars, and car workers' wages are significantly lower than in North America, Europe and Japan. Figure 8. The Brazilian car industry: stages of development. 1. Foreign transnationals assembling components mainly produced in developed countries for the Brazilian market. 2. Foreign transnationals assembling components mainly produced in Brazil for the Brazilian market. 3. Foreign transnationals assembling components mainly produced in Brazil for the South American market in general. 4. Foreign transnationals exporting parts and some cars to developed countries. Future 5. Foreign transnationals exporting cars to developed countries in significant volumes. 6. Brazilian car manufacturer(s) compete for the domestic market with foreign transnationals. Slovakia: a growth location in the new EU The car industry is also expanding fast in Eastern Europe, particularly in some countries that joined the EU in May 2004. Slovakia, with a population of just over five million, has been dubbed ‘the Detroit of Europe’ by at least one writer. Prior to EU membership, Slovakia already boasted a Volkswagen plant with an output of 250,000 cars a year. The Bratislava plant is one of the top three Volkswagen factories in the world, producing the Polo, the Touareg and the SEAT Ibiza. The Touareg is almost totally produced in Slovakia. In 2004, Volkswagen produced almost a quarter of all Slovakia’s exports. Although Volkswagen did not receive a subsidy from the Slovak government, the company is benefiting from a ten-year tax concession. A VW spokesperson has been quoted as saying ‘Volkswagen voted for Bratislava because of the good infrastructure of this region – highway, railway, airport and river transport’. Slovakia enjoys a strategic location on the border with Austria. In late 2004, Slovakia fended off fierce competition from Poland and Hungary to seal a deal with the Korean company, Hyundai, to build its first European car factory in the country. The factory, which should open in 2006, will produce up to 200,000 vehicles a year under Hyundai’s Kia brand. The location of the factory is near Zilina, 200 kilometres northeast of Bratislava. Some of Slovakia’s East European competitors have criticised the amount of the Slovak subsidy to Kia – 228 million euros. In addition, the state is paying 1,750 euros for each of the 3,000 workers. The total cost of Kia’s investment will be $870 million. As with other large car plants, Kia is attracting some of its main suppliers to locate nearby. With its seven suppliers, the total investment is estimated to be $1.4 billion. In January 2006, Peugeot will open a large new car plant in Trnava, 50 kilometres from Bratislava. When it reaches maximum production, this state-of-the-art plant will export 300,000 cars a year to Western Europe and to other parts of the world. This greenfield investment will cost around 700 million euros. Apart from low wage costs, a major attraction of this location to Peugeot was the promise of free land. The new Peugeot factory is attracting many of its suppliers to the same location. In total, it is estimated that 10,000 new jobs will be created. The Slovak Investment and Trade Development Agency (SARIO), established in 2001, played an important role in attracting Peugeot Citroen to the country. SARIO offered a range of potential sites for the new factory. The far-off sourcing of parts The large car manufacturers are looking more closely into sourcing parts from countries such as India and China, which could reduce autoparts bills by 25 per cent. Traditionally most parts have been supplied from the same or neighbouring countries. Very often, parts suppliers have clustered around large assembly plants. However, this geographical bond is weakening. There are some difficulties with sourcing parts from further away, such as the need to enter into longterm relationships with new suppliers, as well as changing factors such as exchange rates and wage levels. This prospective change in the car industry will not occur overnight, but the potential cost savings make it likely. The UK car industry While the record of British manufacturers in the UK has been a tale of woe, foreign car producers have been doing well in Britain. As a result of high foreign direct investment, Britain has a wider range of car manufacturers than anywhere else in Europe. Eight volume brands are made in Britain along with Rolls-Royce, Bentley and niche producers such as Morgan and Lotus. Figure 9 shows production figures for major manufacturers in the UK between 1995 and 2004. In 2003, the motor vehicle industry (vehicles and parts) accounted for just over ten per cent by value of all UK manufacturing, up from 7.8 per cent in 1995. As large employers, the big car companies are of great economic importance in the regions in which they are located. Figure 9. Top manufacturers in the UK. 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004e Nissan 215 232 272 289 271 327 296 297 332 325 Toyota 88 117 105 172 179 171 155 212 211 240 Peugeot 78 85 85 71 162 186 186 198 207 180 Honda 91 106 108 112 114 75 112 177 185 199 BMW 0 0 0 0 0 0 42 160 174 183 Land Rover 100 97 107 149 154 160 139 155 148 155 MG Rover 374 376 395 329 226 175 163 147 133 100 Jaguar Daimler 41 39 44 50 86 89 122 123 126 132 General Motors 262 297 284 277 339 290 193 125 124 130 Ford 274 328 302 298 255 155 72 13 0 0 0 0 0 0 0 0 12 23 18 18 Others Total 1,523 1,667 1,702 1,747 1,786 1,628 1,492 1,630 1,658 1,663 Figures are in thousands. Source: The Auto Industry website, http://www.autoindustry.co.uk/. In 2004, Toyota reported its first back-to-back annual profit in the UK for eight years. Toyota’s car plant is at Burnaston in Derbyshire and it manufactures engines in Deeside, North Wales. Its 2004 profits of more than £30 million are expected to rise to £50 million in 2005. However, the picture has not always been as good. Since both factories opened in 1992, Toyota has lost £780 million over the thirteen-year period. A recent £50 million investment completed in April 2005 allows the Burnaston plant to produce cars at the rate of one every 45 seconds, compared with 57 seconds previously. Toyota can now also move from ‘raw steel to completed car’ in just 19.5 hours. Eighty per cent of production is exported. One factor that can affect profits is the level of the euro against the pound. If the euro strengthens against the pound, it makes British-made cars cheaper for people in other countries to buy, leading to an increase in exports. However, because the two currencies can fluctuate considerably over time, Toyota has reduced the impact of the pound/euro relationship by cutting the ‘UK content’ of each car from 67 per cent to 47 per cent since 1992. Production at Toyota topped 200,000 in 2004. Toyota claims it is on course to sell 1.2 million cars in Europe by 2010. A quarter of these cars will be made in the UK. Nissan’s Sunderland factory remains the most efficient in Europe. It is the largest plant in the UK. The production of two new models in the next couple of years will increase production to 300,000 cars a year. Honda is also represented in Britain with its location in Swindon, having more than doubled its production since 2000. The company is on course to produce 250,000 units a year. All three Japanese companies use the UK as their main production base for European sales. Figure 10. Imported cars at the port of Southampton. The considerable level of foreign direct investment in car manufacturing in the UK means that Britain has a wider range of car manufacturers than anywhere else in Europe. As a result, Britain remains one of the world’s biggest car exporters and is poised to overtake Germany as Europe’s biggest car exporter. The collapse of Birmingham car manufacturer MG Rover in April 2005 has had indirect as well as direct consequences. When the Longbridge car plant collapsed, its 6,100 workers were making 150,000 cars a year. There is now no British-owned mass manufacturer left in the UK. Previous to this, BMW had bought Rover from British Aerospace in 1994. However, six years later, after encountering serious difficulties, it gave the company away to a consortium of businessmen and employees. BMW retained the successful Mini brand manufactured in Oxford. One significant concern is the long-term effect on the UK supply base. Once suppliers are forced to close because of a lack of current demand, it is very difficult to get them back. Industry experts estimate that by the end of this decade the UK will be making more cars than at any time since the 1970s, when a record 1.9 million cars a year were produced. This is good for Britain’s balance of payments because the car industry is currently a net exporter. About 70 per cent of the 1.7 million cars made in the UK are exported. There was concern that being outside the ‘Eurozone’ might weaken the UK’s position in the global car industry. However, these worries seem to have receded. Nissan, a major initial critic of Britain’s decision to keep the pound, now says that the issue is no longer important to its strategic planning. Although the position with regard to car production is healthy in the UK, the same is not true for car components, with a significant number of closures over the last decade. It is the most labour-intensive component manufacturers that have been worst hit. For example, for Nissan’s new Micra, 80 per cent of the components come from elsewhere in the EU, with only twenty per cent from the UK. For the previous version of the Micra, 80 per cent of parts came from Britain. The reasons for this trend are: Increasing competition from lower-cost producers abroad. The strength of the pound. Lack of investment in research and development. Jaguar’s XJ saloon illustrates the complexity of car manufacturing. The components come from a wide range of companies, many of which are multinationals. Jaguar is unable to say what proportion of the car is made in Britain, although it pays for 55 per cent of components in pounds, 30 per cent in euros and fifteen per cent in dollars. Conclusion The car industry is a classic example of mass production and mass consumption. It has responded to the emergence of new markets by major changes in location. In terms of production techniques, the huge success of Japanese manufacturers has led to other major car companies adopting similar methods. However, further changes will undoubtedly occur in the future. According to a recent article in The Economist (2/9/04), these are likely to be: Fragmentation of the market leading to lower production runs. Building cars to order rather than for stock. Innovative modular construction in which more of the car is put together by parts suppliers. A switch to electric cars with electronic and electrical rather than mechanical controls.