CP 20 final report 2007

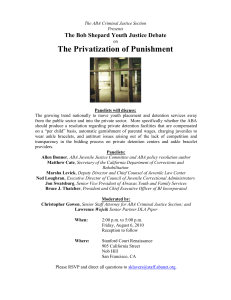

advertisement