LINEAR PROGRAMMING: INTRODUCTORY CONCEPTS

advertisement

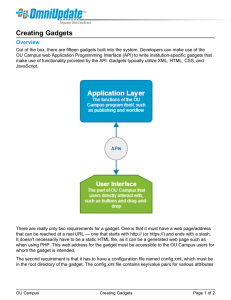

LINEAR PROGRAMMING: INTRODUCTORY CONCEPTS LINEAR PROGRAMMING: GRAPHICAL SOLUTION (Maximization Problem) Session Objectives To introduce students to the fundamental principles behind linear programming To familiarize students with the basic structure, assumptions and limitations of linear programming formulation To discuss the graphical approach in solving linear programming problems and illustrate how this approach could be used in handling maximization problems Main Reference: Chapter 7, Sections 7.1-7.4, pp.216-236 What is Linear Programming? Linear Programming (LP) is a mathematical optimization technique. By optimization technique, we are usually referring to a method which attempts to maximize or minimize some objective, for example, maximize profits or minimize costs. Linear programming is a subset of a larger area of mathematical optimization procedures called mathematical programming, which is concerned with making an optimal set of decisions. In any LP problem, certain decisions need to be made. These decisions are represented by decision variables which are used in the formulation of the LP model. Basic Structure of a Linear Programming Problem The basic structure of an LP problem is either to maximize or minimize an objective function while satisfying a set of constraining conditions called constraints. Objective function. The objective function is a mathematical representation of the overall goal stated in terms of the decision variables. Constraints. Constraints are also stated in terms of the decision variables, and represent conditions which must be satisfied in determining the values of the decision variables. Linear Programming Assumptions and General Limitations When using LP to solve a real business problem, five assumptions (also referred to as limitations) have to be made. Linearity. The objective function and constraints are all linear functions, that is, every term must be of the first degree. Linearity implies the next two assumptions. Proportionality. For the entire range of the feasible output, the rate of substitution between the variables is constant. Additivity. All operations of the problem must be additive with respect to resource usage, returns, and cost. This implies independence among the variables. Divisibility. Non-integer solutions are permissible. Certainty. All coefficients of the LP model are assumed to be known with certainty. Remember, LP is a deterministic model. Computational Techniques to Overcome the Limitations of LP There are at least three other mathematical programming techniques that may be used when the assumptions (limitations) above do not apply to the problem. These are: Integer programming Dynamic programming Quadratic programming The Red Gadget-Blue Gadget Problem We shall be using one particular example to illustrate most of the LP approaches and concepts. We shall call this the red gadget-blue gadget problem. A company produces gadgets which come in two colors: red and blue. The red gadgets are made of steel and sell for 30 pesos each. The blue gadgets are made of wood and sell for 50 pesos each. A unit of the red gadget requires 1 kilogram of steel, and 3 hours of labor to process. A unit of the blue gadget, on the other hand, requires 2 board meters of wood and 2 hours of labor to manufacture. There are 180 hours of labor, 120 board meters of wood, and 50 kilograms of steel available. How many units of the red and blue gadgets must the company produce (and sell) if it wants to maximize revenue? The Graphical Approach Step 1. Define all decision variables. Let x1 = number of red gadgets to produce (and sell) x2 = number of blue gadgets to produce (and sell) 2 Step 2. Define the objective function. Maximize R = 30 x1 + 50 x2 (total revenue in pesos) Step 3. Define all constraints. (1) (2) (3) 50 (steel supply constraint in kilograms) 2 x2 120 (wood supply constraint in board meters) 3 x1 + 2 x2 180 (labor supply constraint in man hours) x1 , x2 0 (non-negativity requirement) x1 Step 4. Graph all constraints. X1 3 Step 5. Determine the area of feasible solutions. X1 Step 6. Determine the optimal solution. The shot-gun approach List all corners (identify the corresponding coordinates), and pick the best in terms of the resulting value of the objective function. (1) x1 = 0 x2 = 0 R = 30 (0) + 50 (0) = 0 (2) x1 = 50 x2 = 0 R = 30 (50) + 50 (0) = 1500 (3) x1 = 0 x2 = 60 R = 30 (0) + 50 (60) = 3000 (4) x1 = 20 x2 = 60 R = 30 (20) + 50 (60) = 3600 (the optimal solution) (5) x1 = 50 x2 = 15 R = 30 (50) + 50 (15) = 2250 4 The contour-line approach Assume an arbitrary value for the objective function, then graph the resulting contour line. Let R = 3000 30 x1 + 50 x2 = 3000 x1 = 0 x2 = 60 x2 = 0 x1 = 100 If you are maximizing, draw contour lines parallel to the first contour line drawn, such that it is to the right of (and above) the latter, and touches the last point (points) on the area of the feasible solutions. If minimizing, go the opposite direction. X1 Step 7. Determine the binding and non-binding constraints. Observing graphically, we find that the steel supply constraint is non-binding, implying that the steel supply will not be completely exhausted. On the other hand, both the wood supply and labor supply constraints are binding. By producing 20 units of the red gadget and 60 units of the blue gadget, wood and labor will be completely used. 5

![[#BAM-1384] Error was thrown when creating gadget in](http://s3.studylib.net/store/data/008624423_1-6f089c8fcdd44b7b0c03215bf260bf0e-300x300.png)