Sprinkler Plan Review

advertisement

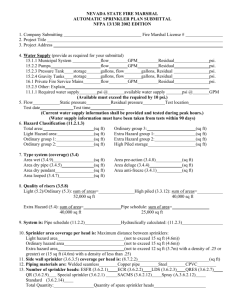

Santa Fe County Fire Department Plan Review for Fire Sprinkler and Standpipe Systems Plan Reviewer’s Name: Date: 1. Project: 2. Project Street Address: 3. City: 4. Fire Protection Contractor Name: 5. Fire Protection Contractor Street Address: 6. City: 7. License/ Registration No: 8. Date of Plan: 8. Signature on Plans: 9. This Form Completed By: 10. Comments: 11. Site Plan: 11.1 Underground Fire Main Size: Located and Dimensioned: Y N 11.2 City Water Main Size: Circulating: Y N 11.3 Proper Pipe Bending Material: Y N Compacted backfill: Y N 11.4 Thrust Block Shown: Y N Clamps/ Rods Noted: Y N 11.5 Water Flow Test: Static psi: Residual psi: 11.6 Number of Outlets Flowed: Size of Outlets Flowed: 11.7 Hydrant Locations Shown: 11.8 Utility Lines Located for Coordination and excavation: Y N 11.9 Adjacent Streets with Names and Locations Shown: Y N 11.10 North direction Indicated: 11.11 Scale on Drawing is Graphically Indicated: Y N 11.12 Paved Parking, Roads and Fire Lanes are Indicated: Y N 11.13 Fire Department Connection Location is Accessible: Y N 11.14 Fire Department Connection located on Building wall: Y N 11.15 Exterior Alarm Device in an Acceptable and Visible Location: Y N 11.16 Water Motor Gong: Comments This Page: Contact Number: State: Zip: State: Zip: Phone No: ( ) Fax No: ( Last Revision Date: Y Y ) Revision Date: N GPM: Distance to FDC: (feet) N Scale on Drawing Note: Light Horn: Electric bell: Y N 12. Hazardous Classification: 12.1 Light Hazard: 12.2 Ordinary Group: 1 2 12.3 Extra Hazard: 1 2 12.4 General Storage to 12 ft. height (NFPA13): Commodity Class: 12.5 General Storage Over 12 ft. Height (NFPA 231): Storage Height: 12.6 Rack Storage (NFPA 231 C) : In Rack Heads: Y N 12.7 Interior Hose Station Information: Required: Y N Supply from Adjacent Overhead System: Y N Supply is Separated Piping System: Y N Description: 3 Description: Storage Height: Supply From Overhead System: 12.8 Applicable NFPA Standard: 12.9 Type of System: 12.10 System Configuration: 12.11 System Area Limitations: Description: Y 13 N 13R 13D 231 231C Wet Dry Combined Dry/ Preaction Deluge Foam Foam / Water Tree Other: Antifreeze Other: Grid Light and Ordinary Hazard: 52000 sq. ft. Max: Warehouse (General and Rack storage over 12ft.): 40000 sq. ft. Max: Extra Hazard (Calculated) 40000 sq. ft. Max: Extra Hazard (Non-Calculated) : 25000 sq. ft. Max: Dry System Capacity: Gal: Anti-freeze system Gal. 12.12 System Design Criteria: Density: Remote Area size: Sq. ft. 12.13 Remote Area Length Determined by: NFPA 13 (1.2 Remote Area Size) 12.14 Dry System Remote Area Increased by 30% (Minimum 1960 sq. ft.) 13. Type of Construction (NFPA 13, para. A-1-4.6)a), 4-4.1.4.3) 13.1 Type and Description of Obstructed Construction: Y N Other: Sq. ft. Beam and Girder (Spacing 3-0 to 7-6 ft. on Center) Size: Spacing: Composite wood Joist (Spacing less than 3-0) Size: Spacing: Panel Construction ( Beams Spaced More Than 7-6 ft. on center, Not over 300 sq. ft.) Beam Sizes: Wood Joist Construction: Size: Spacing: Concrete Twin “TT” : Size: Spacing: Other: 13.2 Type and description of unobstructed construction: Bar Joist: Size: Spacing: Smooth Ceiling: Open Grid Ceilings: Standard Mill Construction: Wood Truss Construction Size: Spacing: Other: 13.3 Roof Construction: Combustible: Non-Combustible: 13.4 Ceiling Construction: Combustible: Non-Combustible: 13.5 Attic Space uses as an air Plenum: 13.6 Fire Separation Walls / smoked Barriers / Floor Penetrations Fire Caulked: Y N 13.7 Draft Curtains: Y N Smoke / Heat Vents: Y N 13.8 Skylights / Glass Roofs: Y N Ceiling Elevation Defined: Y N 13.9 Earthquake and/ or Sway bracing Required: Y N 13.10 Hanger Material Defined: Y N Comments this Page: Steel Fire Proofed: 14. Sprinkler Head Spacing and Information: 14.1 Actual Head Spacing on Drawing: Light Hazard: Sq. ft. per Head Ordinary Hazard: Sq. ft. per Head Extra hazard pipe Schedule: Sq. ft. per Head Extra Hazard Calculated Sq. ft. per Head High piled storage with density below .25 (max 130 sq. ft.) High piled storage with density over .25 (max 100 sq. ft.) ESFR Sprinkler heads (Max 100 sq. ft.) Large drop sprinkler: Extended coverage or upright or pendent: Sq. ft. per head Sidewall heads: Sq.ft. Small room rule applied: Extended coverage: Y Other: 14.2 Deflector distance below roof or ceiling: Unobstructed Construction: Spray Heads 1” to 12” Sidewall Heads 4” to 6” 14.3 Special Considerations Min. 18” Clearance from deflector to top of storage: Y N Min. clearance from deflector to top of storage: Y N Temperature rating identified: Y N Heater Zones: Y N Ventilated Attic: Y N Unventilated Attic: Y N Skylights (Plastic or glass) Unventilated Showrooms: Y N Single level of sprinklers in rack: Y N Multiple Level of sprinklers in rack: Y N 15. Riser and Valve Arrangement: 15.1 Single Wet Riser: Y N 15.2 Single Dry Riser: Y N 15.3 Multiple System Riser Valve arrangement with a single lead in supply: Y N 15.4 The required relief valve is shown on a wet grid system: Y N 15.5 Water pressure gauges are provided above and below the main check valve: Y N 15.6 Is the inspectors Test connection valve and discharge location acceptable: Y N 15.7 Auxiliary drains are indicated on secondary mains of gridded system: Y N 15.8 Are auxiliary drains and discharge for trapped sections of piping shown: Y N Comments this page: Sq.ft. N Sq. ft. 16. Standpipe System: Low Rise Buildings 16.1 Interior Hose stations: Y N Exterior hose stations: 16.2 Supply from sprinkler System: Y N Separate control valves: 16.3 Size of sprinkler pipe supplying interior hose stations: 16.4 Size of pipe to interior hose stations: 16.5 Hose station with hose: Y N 16.6 Size of valve: 1.5 inch: Y N 16.7 Type of nozzle: 16.8 Minimum Nozzle operating pressure: 16.9 Other: 17. Standpipe System: 17.1 Height from grade to roof: 17.2 Roof Manifold piping equipped with ball drip drain: 17.3 Roof Manifold: 17.4 Hose valve cap: Pressure regulating type valve: Pressure restricting type valve: Pressure adjusting type: Factory set/ non adjustable: Hose valve with hose: Number of stories: Inch Pipe Inch 2.5 In. Adjustable: N Cabinet: Y N Y N 2.5 x 1.5 Reducer Y N Other: Discharge Gpm. Number of stories: Feet N N Y High rise building Y Y Feet Straight: Psi. N Feet Length of pipe: Rack: Y Pressure gauge at top: Roof manifold equipped with hose valves: Y N Y N Y N Y N Other: 17.5 17.6 Types of standpipe system: Class of standpipe system Automatic-Dry Automatic-Wet Manual Dry Manual Wet Semi-automatic Dry Class 1 (Trained for fire department use) Class 2 (Untrained Building Occupants) Class 3 (Trained and Untrained personnel) 17.7 Are valued outlets provided on each side of every pressure regulating device for testing and maintenance? Y N 17.8 Are manual control valves provided at the standpipe raiser? Y N 17.9 Is minimum residual 100 psi provided at the top most remote: Y N 17.10 250 gpm with a maximum of 1250 gpm required in a fully sprinkled property: 17.11 Class 2 minimum flow rates T the top of the most remote: Y N 17.12 Standpipe is sized by: 18. Special Fire Pump and Supplemental Water Supply Information: 18.1 Public City Water Supply 18.2 Elevated Tank Pipe schedule Circulating Capacity: Open Reservoir Feet Feet Y Inches N Rubberized Bladder tank Deadend Gallons Year installed: Ground Storage: Diameter: 18.4 Hydraulic Calculated System Name: Height to bottom of tank : 18.3 Total GPM Required: 100gpm Height: Y N Capacity: Gallons Feet Inches Capacity: Gallons Other: 18.5 Electric Driven Pump 18.6 Type of controller: 18.7 Gpm: Comments this page: Diesel Driven Pump Vertical Horizontal Transfer switch provided Discharge psi: Y Suction Pressure psi: N