NFPA 13-Installation of Sprinkler Systems

advertisement

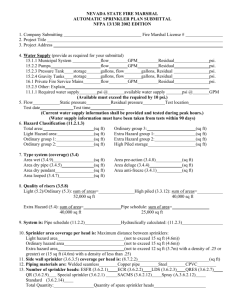

“Meet the DBI Pros” Summit October 12, 2007 WELCOME TO THE AUTOMATIC SPRINKLER ‘SUMMIT’ PRESENTED BY THE SAN FRANCISCO FIRE DEPARTMENT “MEET THE DBI PROS” THE SAN FRANCISCO FIRE DEPARTMENT PRESENTS NFPA 13-Installation of Sprinkler Systems: Transition from 1999 to 2002 Editions By: Gerald Zari and Jon Corbett Reorganization of the NFPA 13 Standard: • NFPA 13, 2002 Complies with the NFPA Manual of Style: – First Chapter is “Administration” – Second Chapter is “Reference Publications” (previously Chapter 13) – Third Chapter is “Definitions” – Changes/additions indicated with a vertical bar The “Administration” Chapter provides general guidance for the following aspects of Sprinkler Systems: – Scope: Minimal design & installation of systems. – Purpose: Reasonable degree of protection – Application: Water Supplies, sprinklers, piping, fittings and Materials used – Retroactivity Clause: The AHJ can apply this standard to existing systems where there is an “unacceptable degree of risk” – Equivalency: Allows the AHJ to accept alternate approaches, based on engineering judgment, that meets the intent of the standard – New Technology: Accepts the use of newly developed sprinkler, fittings, etc…within their listings Referenced Publications: – Updated to the most current, applicable Standards – Directs user to other standards for design of sprinkler systems not addressed in NFPA 13 New Definitions: – Bathrooms in Dwelling units – Ceilings: Flat, Horizontal, and Sloped – Materials: Non-Combustible and Limited Combustible; consistent with NFPA 220 Chapter 4: Owners Certificate (4.3) • A new form with information provided by the • • • • Owner or an Authorized Agent States intended use of building, materials within and storage heights Provides a preliminary building plan for design of the sprinkler system If applicable, special information about the water supply and Microbiologically influenced corrosion (MIC) SFFD may require this form on the approved plans Chapter 6 (1999 Chpt.3): System Components and Hardware • Specially listed products (6.1.1.1) – Installation must conform to all conditions required by the listing, this information is found in the product literature and installation instructions – Examples: WS sprinklers, extended coverage, flex heads and residential sprinklers Chapter 7 (1999 Chpt.4): System requirements • Gauges are now required above and below check valves in a Riser, i.e. both sides • Freezing conditions: areas where Temperatures are below 40 degrees Fahrenheit Chapter 8 (1999 Chpt.5): Installation Requirements • Sprinkler thermal sensitivity (8.3.3) – Per 8.3.3.3, where Quick Response (QR) sprinklers are installed, all sprinklers in that room/compartment are required to be QR ordinary temperature-rated (135-170 0F) – The exception is a circumstance that requires a higher temperature sprinkler, e.g. a heat source like a Fire Place Stove or skylight, then use of Standard sprinklers is permitted – Does NOT apply to Residential Sprinklers Chapter 8, continued: • Sidewall Spray Sprinklers (8.4.2): – Light Hazard: Allows installation of sidewall sprinklers in smooth, horizontal or sloped ceilings – Deflector Orientation (8.7.4.2.2): • In sloped ceilings: locate sprinkler in highest point of slope with deflector parallel to slope – Definitions: • Smooth Ceiling: a continuous ceiling free of significant irregularities • Horizontal Ceiling: 2:12 slope or less (10o) • Sloped Ceiling: Greater than a 2:12 slope (>10o) Chapter 8, continued: • Skylights and Similar (Small) Ceiling Pockets (8.5.7): – Omission of Sprinklers allowed in openings if: 1. Opening does not exceed 32 ft2 AND 2. Edges of openings are horizontally separated by 10feet or more to other openings Example: 4’-0 Max 32 ft2 8’-0 10 feet or more 2’-0 Max 32 ft2 16’-0 Chapter 8, continued: • Ceiling Pockets (8.6.7) – Sprinklers required except where ALL of the conditions listed below are met: 1. Volume (cubic feet) is 1000 ft3 or less 2. Maximum of 36-inch deep 3. Entire floor area below has sprinkler coverage 4. Adjacent openings are horizontally located 10-feet or more away from any other pockets 5. Construction is limited/non-combustible 6. Skylights allowed to be plastic if 32 ft2 or less 7. Quick Response sprinklers are used in the room Chapter 9 (1999 Chpt.6): Hangers, Bracing , and Restraint of System Piping • Fasteners in Concrete (9.1.3) – Installed in the Horizontal position unless one of the following conditions is met: • Used in concrete with gravel/crushed stone for supporting up to 4-inch pipe • Alternated with hangers connected to structural members or sides of concrete beams for 5-inch or larger pipe • Spacing is 10-feet or less for 4-inch and larger pipe Chapter 9, continued. • Unsupported Ends of Branch Lines (BL) and Armovers with static/flow pressures exceeding 100 psi (9.2.3.4.3 and 9.2.3.5.2): – Steel Pipe requires a hanger and vertical restraint within 12-inches of the BL and armover end – Copper Tube requires a hanger and vertical restraint within 6-inches of the BL and armover end Chapter 9, Continued. • Risers (9.3.5.5) – 4-way braces required for risers more than 3feet in length. – 4-way braces not required where riser penetrates intermediate floors of a multistory building where clearances required by 9.3.4 are not exceeded. A QUICK COMPARISON OF NFPA 13, 13R, AND 13D STANDARDS QUICK COMPARISON OF NFPA 13, 13R, AND 13D STANDARDS REQUIREMENT NFPA 13 SPRINKLERS THRU-OUT ALL AREAS/ALL OCCUP. NFPA 13R NFPA 13D X SPRINKLERS IN ‘R’ OCCUPANCIES UP TO 4 STORIES X X SPRINKLERS IN ‘R-3’- 1 & 2 FAMILY DWELLINGS X X EXTRA STORY 2007 CBC TBL 503 X NOT ALLOWED NOT ALLOWED MORE AREA 2007 CBC TBL 503 X NOT ALLOWED NOT ALLOWED X CLOSETS:* HOTEL/MOTEL CLOSETS 24 sq. ft. or less N/A HOTEL/MOTEL CLOSETS greater than 24 sq. ft. X X N/A CLOTHES/LINEN CLOSETS/PANTRIES (nonhotel/motel) 24 sq. ft. or less X CLOTHES/LINEN CLOSETS/PANTRIES (nonhotel/motel) Greater than 24 sq. ft. X X X X X X BATHROOMS:** BATHROOMS 55 sq. ft. or less BATHROOMS greater than 55 sq. ft. DESIGN: NFPA 13 RESIDENTIAL @ 0.1GPM/sq. ft. (or listed flow >0.1 gpm, res. Sprinkler) X RES. OCC. USE QUICK RESP./ CALC. 1500 sq. ft. X RES. OCC. USE RES. SPRKLRS/ CALC. 4 HEADS X NFPA 13R X RES. OCC. USE RES. SPRKLRS/ CALC. 2 HEADS & 1HEAD CALC. X NO HOSE ALLOWANCE REQUIRED (must include domestic use) RES. OCC. ADD 100 GPM HOSE ALLOWANCE MUST USE LISTED RESIDENTIAL SPRINKLERS X X X X X X X QR or RES. MINIMUM DENSITY 0.05GPM/sq. ft. (listed sprinkler flow) MINIMUM OPERATING PRSS. OF 7 PSI NFPA 13D X X X MISCELLANEOUS AREAS: NFPA 13 GARAGES (requires 250gpmhosedemand) X ATTICS/CRAWL SPACES/CONCEALED SPACES-NOT INTENDED FOR STORAGE OR LIVING PURPOSES X NFPA 13R NFPA 13D Refer to NFPA 13 Refer to NFPA 13 *The least dimension not exceeding 3’. **The walls and ceilings must be non or limited-combustible construction. 4.02 Fire Department Connection Omission • In the past, it was the Fire Department's position to allow the • • • • • omission of a Fire Department Connection in buildings with fewer than 20 sprinkler heads per floor. This was allowed by N.F.P.A. 13, as it left the decision up to the Authority Having Jurisdiction. However, due to Standard changes, the 2002 edition of N.F.P.A. 13 (8.16.2.2) no longer allows the omission of an FDC except in the following circumstances: Exception 1. Buildings located in remote areas that are inaccessible for fire department support. Exception 2. Large-capacity deluge systems exceeding the pumping capacity of the fire department. Exception 3. Single-story buildings not exceeding 2,000 sq. ft. in area. Two additional exceptions for the requirement for FDC's are found in the 2001C.B.C. , Section 904. The first pertains to combination domestic/fire services. When approved by the Fire Department, the FDC may be omitted in these systems. The second exception applies to Group I Occupancies housed in existing single family dwellings under certain conditions (see 2001 C.B.C. , section 904.1.2, exception 4). It is the Fire Department's position that an FDC will be required except in the instances outlined above. 4.04 Color Coding of Existing Standpipes • Reference: 2007C.B.C. Section 905.4.2 • It is the Bureau of Fire Prevention's policy that all standpipe systems with multiple risers be interconnected at their base. However, existing systems that were approved and installed without such interconnection may have their use continued if such standpipe system is provided with an approved color code. Color code markers shall be of a permanent material at least one inch wide surrounding the flange of the standpipe inlet. All outlets supplied by this inlet shall be equipped with similar marking. • If the standpipe is exposed, the pipe directly above the outlet handle shall be marked with a color band at least one inch wide which is the same color as installed at the inlet which supplies such outlet. If the standpipe is enclosed by construction, such markings shall be located on the wall directly behind the standpipe outlet. This marking may be a 3 inch color disk or 3 inch square area and shall be the same color as the inlet which supplies such outlet. • The Bureau of Fire Prevention will accept five colors which must be florescent: hospital white, royal blue, canary yellow, fire engine red, and bright orange. 4.05 Protection of Standpipe Inlets • Reference: 2007C.F.C. Section 912, 2003 NFPA 14 Section 12.9 • THE SAN FRANCISCO FIRE DEPARTMENT'S REQUIREMENTS FOR THE PROTECTION OF STANDPIPE INLET THREADS ARE: • 1. Hose connections for standpipes shall be • equipped with an approved plastic or metal plug which may be removed and reused. 2. The use of cast iron caps which are not threaded shall not be used. 4.06 Design Criteria for Fire Department Connections and Standpipe Outlet Valves • Reference: 2003 N.F.P.A. 14 • Fire Department connections shall be located not less than 18 inches nor more than 48 inches above the level of the adjoining ground (NFPA 14 sec. 6.3.6). • Each standpipe shall be equipped with approved outlet valves which discharge horizontally. They shall be located not less than three feet nor more than five feet above the floor. NFPA 14 sec. 7.3.1 • The recommended height is 42 inches from the finished floor to the center line of the valve.) It shall be placed to provide a minimum clearance of six inches on all sides of the handle and 12 inches on all sides of the threaded outlet. All measurements are to be taken from the finished surface to the handle or outlet • Connections and outlets shall be placed so that doors or walls do not interfere with the use of the outlet valve. • Fire Department connections and outlet valves shall have "3" inch National Standard hose threads. 4.08 Design Criteria for Installation of Underground Piping for Fire Sprinkler Service Reference: 2007 C.B.C. Sec. 903 NFPA 24, 2002 edition, section 10.4.3, requires that the depth of cover for fire service main pipe be not less than 30 inches or one foot below the frost line for the locality. Where frost is not a factor, the 30 inch depth of cover is required to protect the pipe from mechanical damage. The San Francisco Water Department supplies domestic water meters for all fire services of two-inch and smaller, including combination fire/domestic services. These meters require that the pipe be installed less than the 30 inches required by N.F.P.A. 24. Due to the practical difficulty of compliance with this standard, all twoinch and smaller fire services, including combination services, shall be allowed to be installed following the criteria listed below which will prevent mechanical damage: 1. All installation of piping shall comply with San Francisco Plumbing Code section 609.1 which requires a minimum depth of cover of 12 inches below finished grade. 2. A minimum four inches of concrete shall cover the area above the pipe. The four inch concrete installation shall extend a minimum of 12 inches horizontally on both sides of the pipe. 3. A minimum of three inches of earth shall be maintained between the pipe and concrete. Exception: Pipe and joints that have been coated and wrapped do not have to comply with requirement number 3. 4.09 Removal of Class II Standpipe Hose Cabinets in Sprinkler-Retrofitted Buildings Section 901.8 of the 2007 C.F.C. requires written Fire Marshal approval in order to remove existing fire appliances. In order to speed the permit process, buildings subject to the San Francisco High-rise Sprinkler Ordinance will be permitted to remove Class II Standpipe hose cabinets on individual floors after they have been fully sprinklered. The applicant shall state his or her intention to remove the hose cabinets on the approved sprinkler plans. • Buildings not subject to the ordinance will continue to require written Fire Marshal approval in order to remove any fire appliance. These written requests will be considered on a case-by-case basis. 4.10 Testing of Fixed Extinguishing Systems (Standpipes and PRV's) • Reference: C.A.C. Title 19, Chapter 5 • Title 19, California Administrative Code , includes regulations for Automatic • • • Extinguishing Systems. Chapter 5 contains the criteria and time frames for maintenance and service inspections for all fixed automatic extinguishing systems. Sections 904.2(i) and (j) permit the local Fire Department to require notification prior to any service inspection and also to be sent a report of the results. The San Francisco Fire Department shall be notified at least twenty-four (24) hours prior to any servicing of a system. Also, a report of the results of any service inspection shall be forwarded to the San Francisco Fire Department at: San Francisco Fire Department Bureau of Fire Prevention 698 Second Street San Francisco, California 94107 4.10 Testing of Fixed Extinguishing Systems (Standpipes and PRV's) - continued • Pressure Reducing Valves-Certification Of • Section 904.4(c)(3) and (d)(3)-Service Regulations for Class III and • • • • • Combined Standpipe Hose Outlets state that "Each Hose Valve Outlet shall be inspected in a manner that will indicate the valves are fully operable." The primary function of a PRV type hose outlet is to reduce pressures under both flow and no-flow conditions. The only way this pressure reducing feature can be tested and certified as operational is to flow test the valve. All PRV type hose outlets shall be flow tested for certification. The following test results and information shall be submitted to the Fire Department for review: valve type or model, valve pressure setting, reduced static pressure, outlet residual pressure flowing 500 g.p.m. for the first standpipe and 250 for each additional standpipe with the pump running at its rated capacity. PRV hose valves shall be certified as per the design criteria at the time of their installation. Hose valve design criteria for new installations require outlet pressures of 100 to 125 psi residual pressure flowing 250 g.p.m. and 75-100 psi residual pressure when flowing 500 g.p.m. from the roof manifold of the hydraulically remote standpipe and 250 g.p.m. for each additional standpipe. Maximum static pressure must not exceed 150 psi. All test results will be reviewed by the San Francisco Fire Department. 4.20 Design of Fire Pump Suction Piping and Fire Pump Location • Reference: NFPA 20-2003, Section 5.2.4 • Design of the fire pump suction pipe must be approved by the Fire Department. As required by NFPA 20, fire pump suction piping from the city main and fire water storage tank to the fire pump suction flange shall be designed and installed to avoid air pockets. For this reason, the location of the fire pump will also be reviewed and approved by the Fire Department before the Site Permit is approved and issued. • For new building installations, air pockets in the fire pump suction piping is not allowed. Providing an automatic release valve for the air pockets instead of avoiding air pockets is not acceptable. • For existing buildings, design of the fire pump suction piping must avoid air pockets. If it is impossible to do so, the Fire Department will review these installations on a case-by-casebasis. • 4.23 Combination Fire Services • Reference: 2007C.B.C. , Sections 903.3.1.5.2, NFPA 13• • • • 2002, NFPA 13R-2002 A. Combination fire service will be permitted only when the combined sprinkler system and domestic water demand through the meter will not exceed the manufacturers' listed maximum, intermittent delivery rate. The following guidelines will be used to comply with this policy: SPRINKLER SYSTEM DESIGN CRITERIA Sprinkler systems supplied by the combination fire service must be hydraulically designed in accordance with NFPA 13D, 13R and/or 13 as required by the C.B.C. , the Department of Building Inspection, and the Fire Department. The domestic water demand must be included in the sprinkler flow at the domestic water system point of connection to the combination fire service line. Domestic water demand shall be at least 5 gpm per unit for two dwelling units or less. For three or more dwelling units, the domestic demand shall be as estimated using the Tables in NFPA 13R. – The maximum delivery rates for combination fire service are: 1 inch service = 50 gpm 1 1/2-inch service = 100 gpm 2 inch service = 160 gpm The meter friction losses to be used in the hydraulic calculations are: Service size\flow 25 gpm 50 gpm 75 gpm 100 gpm 150 gpm 160 gpm 1 inch 5 psi 9 psi 1.5 inch 1 psi 3 psi 7 psi 12 psi 2 inch 1 psi 1 psi 3 psi 5 psi 8 psi 12 psi – B. Combination Fire Service Pipe – For all sizes, the service line must be copper (Type K with brazed joints) from the meter to the sprinkler connection to minimize problems of tuberculation. • 4.24 FDC Requirement for Low-Rise Buildings • Reference: NFPA 13 NFPA 14 • The San Francisco Fire Department may require more than one FDC in a low-rise building when: • 1) The building fronts on more than one public way. • 2) It has significant floor area where firefighter response to the seat of the fire may be delayed. • 3) The adjacent streets or public way characteristics may hinder firefighting operations. – 4) Deemed necessary for any other reason by the Fire Department. – FDC locations to be approved by Fire Department. Some 2007 CBC new requirements: • 1. All buildings with a R-1 (hotels) and R-2 (apartments) fire area must be sprinklered throughout. Sec. 903.2.7 • 2. All valves controlling the water supply for automatic sprinkler system must be electrically supervised. Sec. 903.4 • 3. Alarm, supervisory, and trouble signals…… and automatically transmitted to an approved central station, remote supervising or proprietary supervising station as defined in NFPA 72. Sec. 903.4.1 • 4. Systems with 20 or more sprinklers must be supervised and monitored by a central station or equivalent. Sec. 903.4 • 5. All Group ‘A’ occupancies shall be sprinklered throughout and all the floors between the ‘A’ occupancy and the level of exit discharge. Sec. 903.2.1 SEISMIC BRACING REQUIREMENTSCBC 2007 and NFPA 13-2007 CBC Sec. 1613.1 • Design of sprinkler supports and attachments shall be in accordance with ASCE-7 (American Society of Civil Engineers). • Some exceptions are allowed based on specific criteria. • ASCE Sec. 11.4 Seismic Ground Motion Values (SDS or SD1), Occupancy Category values determined by a California registered Engineer. • ASCE Sec. 13.6.8.2 and 13.6.8.3 Seismic design requirements based on Occupancy Category Occupancy Category ‘C’ is based on NFPA 13-2007 Occupancy Category ‘D’, ‘E’, and ‘F’ are required to comply with ASCE 7 • Most buildings in San Francisco appear to fall into the D to F Occupancy Categories. • Categories D to F: ASCE Section 13.6.8.3 Hangers and Bracing designed in accordance with NFPA 13 Design strength, Force and Displacement calcs. by a Calif. Registered Engineer • The SFFD will issue an Administrative Bulletin concerning the specific submittal requirements for Fire Sprinkler Seismic Bracing Thank you for attending! • We value you and your opinion • We want you to feel that we’re here to help assist you • Our goal is to improve the value of our services to better serve you • We’ve been listening to you telling us what’s important • New improvements are on the horizon • Please fill out evaluation form