lab #2 spec sheet

advertisement

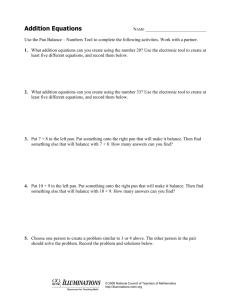

Fall 2006 Intro to Fluid and Thermal Transport – ME 331 Laboratory Assignment #2 Impact of a Fluid Jet C. J. Kobus The schematic above shows the apparatus used to investigate the force resulting from the impact of a jet on a target plate. The apparatus consists of a clear acrylic test cylinder, into which water is fed vertically through a nozzle. The water strikes a target plate mounted on a stem that is free to move upwards or downwards as a result of the force applied by the water jet. A weight pan is mounted at the top of the stem and is attached to a compression spring. The vertical force exerted by the water jet on the target plate is measured by adding weights to the weight pan until the weight pan is aligned with a level gage. The objective of this experiment is to measure and model the fluid jet impact force as a function of the volume flowrate, ∀& , of the fluid leaving the nozzle for three different deflector plates, having deflection angles of 90, 120 and 180 degrees. 1. Using the equipment and the instrumentation provided, run experiments for each of the three deflector plates to determine the steady volume flowrate of the fluid, gpm, necessary to counterbalance the weight pan for a known applied mass, m. Vary the applied mass in the range g 150 m 20 ≤ ≤ , or until you have reached the maximum flowrate that can be measured by the flowmeter. Use weight combinations that allow you to increase the mass by 10-20 g increments. 2. On one graph, plot the applied force (N) versus the volume flowrate (m3/s) for all three deflector shapes. Determine a best-fit curve through the data. Discuss the effect of deflector angle on the force. 3. Plot a graph of the applied force versus velocity squared, V2, for all three deflector plates and show the experimental uncertainty. 4. Using the conservation of mass and conservation of momentum equations, derive the following equation that relates the applied force, W, to the exit velocity, V, of the jet, W=AV 2 (1+ cos where ρ is the water density, A is the cross-sectional area of the nozzle, and θ = π - α, where α is the flow deflection angle. You may neglect the friction between the water jet and the deflector plate and hence assume that the velocity of the sheet of water leaving the deflector plate is essentially the same as the velocity, V, exiting the nozzle. 5. Compare the model predictions to the measured force values. Superimpose the model predictions on the same force versus V2 graph. Comment on the agreement between your theoretical and experimental results. Discuss any sources of discrepancy. Procedure: These instructions cover the steps to be taken in setting up and operating the Armfield F1-16, Impact of a Jet apparatus. Parts of these instructions are extracted from the manufacturer’s complete manuals, which are available upon request or on the manufacturer’s website1. First you will need to remove the three knurled nuts which retain the top plate on the clear acrylic test cylinder, then remove the top plate. Next, screw the selected target plate on the end of the vertical shaft in the apparatus, close the top and hand tighten the knurled nuts on the top. Make sure that the top plate remains level and that the vertical shaft is free to move and is supported by the spring beneath the weight pan. You will need to zero the position of the weight pan by adjusting the height of the level gage until it aligns with the datum line on the weight pan. The apparatus should now be ready for use. Place a weight on the pan. The flow to the Impact of a Jet apparatus is controlled by what is known as a Hydraulics Bench. To control the flow, first close the bench flow valve, start the service pump, then gradually open the bench flow control valve until the level is again aligned with the datum line on the weight pan. Make sure you gently oscillate or spin the weight pan during this process to make certain that pan is in fact free to move and is not stuck. At equilibrium, the downward force exerted by the weight is counteracted by the upward force of the water acting on the target plate. Record the values of flowrate and applied weight, then increase the weight on the pan and increase the flowrate. Make sure that the flow is steady. Repeat until you have either covered the range of weight values specified on your lab handout or until you have reached the maximum flowrate that can be measured by the flowmeter. Next, change deflector plates and repeat the procedure described above.