course description - Alfred State College intranet site

advertisement

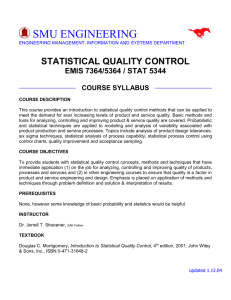

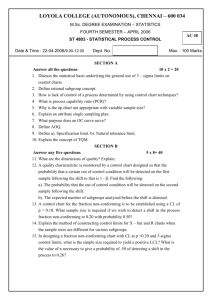

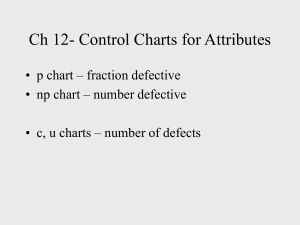

VPAA__________________________ Date____________________________ Vice President/ Academic Affairs Office use only SUNY College of Technology at Alfred SCHOOL: DEPARTMENT: COURSE NAME: COURSE NUMBER: SEMESTER OFFERED: PREREQUISITE: COURSE FORMAT: COURSE LEVEL: FINAL PROJECT: Management and Engineering Technologies Mechanical Engineering Technology Quality and Process Control MECH 6243 Spring Math 2124 3 Credits: Three 1-Hour Lectures. Upper No Date Approved by Faculty Senate: ____________________________________ COURSE DESCRIPTION Topics covered in this course include an introduction to quality control, statistical quality control in manufacturing, cost of quality, control charts, hypothesis testing and other quality improvement methods, process capability, methods and philosophy of statistical process control, process design and improvement, design of experiments, process optimization, lot-by-lot acceptance sampling, other acceptance sampling techniques. STUDENT OBJECTIVES Upon completion of this course the student will: 1. Demonstrate an understanding of the fundamentals of quality and process control through quizzes, tests, exams, and presentations. 2. Construct and use control charts as tools for continuous quality improvement. 3. Apply a statistical approach on quality and process control and perform an acceptance or rejection procedure. 4. Conduct a comprehensive and statistical quality and/or process assessment procedure in order to identify the causes of defects/poor process performance. 5. Construct and perform a design of experiments procedure and determine the factors that need to be adjusted and set up in order to improve quality and or process. Page 1 TEXTBOOK(S) Quality Control + CD, Dale H. Besterfield, ISBN: 0-13-113127-3, Prentice Hall, Latest Edition. PRE-REQUISITE BY TOPIC A general knowledge of basic statistics and adequate preparation in traditional lower division math will be helpful in this course. DIVISION OF SUBJET MATTER Topic A B C D E F G H I J K L M N O P Q R S Philosophy and Fundamentals Total Quality Management, Principles and Practice Total Quality Management, Tools and Techniques Fundamentals of Statistics, Review Statistical Concepts and Techniques in Quality Control Statistical Concepts and Technique in Quality Improvement Fundamentals of Probability, Review Statistical Process Control Control Charts for Variables Control Charts for Attributes Process Capability Analysis Lot-by-lot Acceptance Sampling by Attributes Other Acceptance Sampling Systems Reliability Design of Experiments (DOE) The Taguchi Method or Robust Design Quality Control in The Service Sector Management and Planning Tools Exam TOTAL Total Lecture Hours 2 3 2 3 2 2 3 3 2 2 2 3 2 3 3 2 1 2 3 45 LABORATORY PROJECTS None LIBRARY USAGE None Page 2 COMPUTER USAGE Extensive use of MinitabTM, and Microsoft ExcelTM to make student familiar with the statistical quality control features embedded in these software packages, and facilitate comparison with solutions by hand. BIBLIOGRAPHY Grant, Eugene, Statistical Quality Control, McGraw Hill, Latest Edition. Moen, Ronald, Thomas W. Nollan, Lloyd P. Provost. Quality Improvement through Planned Experimentation, McGraw Hill, Latest Edition. Montgomery, Douglas C. Introduction to Statistical Quality Control, John Wiley & Sons, Latest Edition ___________________________ _______________________ Dean of School Department Chair ____________________________ ________________________ Instructor of Course Date Page 3 STATE UNIVERSITY OF NEW YORK College of Technology at Alfred Request for Course/Curriculum Submission Request Submitted By: Dr. WM Anselm Tshibangu____________________ Date:_9/30/05__________________ Course/Curriculum Title: MECH 6243/Quality and Process Control/Curriculum 622_____________ Forward this with your proposal package to the Curriculum Development and Review Committee after answering the following questions. 1. What are the primary purposes of the course/curriculum change? To provide the high Tech and problem solving skills needed by local manufacturing companies, and industrial partners as well as to respond to SME recommendations in terms of filling up the competency gaps. 2. What will be the impact on current programs - dropping courses, combining courses taught less frequently, increase in required courses, ...? None 3. In what ways will faculty be affected - teaching load, professional development, ...? None 4. What are the resource requirements - faculty resources, equipment, supplies, travel, classroom and/or laboratory space, computer usage, library, ....? Only basic resource requirements will be needed. MS Excel, and statistical analysis packages such as Minitab or SPSS packages are enough for the course. Specific software package, if any, comes with the book. 5. What date do you recommend the change to become effective? Fall 05 6. What do you anticipate will be the effect on the employability and/or transferability of your students? Will enhance employability of students because course responds to employers’ needs, and at the same time, fills up the competency gaps identified by the Society of Manufacturing Engineers. Transferability to higher degree programs (e.g. Master’s) also increased because most MS programs list this course among the requirements. 7. Has the proposal been discussed at a full department meeting? New program, new course/proposal discussed with industrial experts (Industrial Advisory Board Committee) and department faculty. 8. Which other departments would this proposal affect; has it been discussed with them? No department will be negatively affected. To the contrary, students from all departments may benefit from this course. 9. Has a list of at least five (5) available resources, pertinent to the course, been included in the course outline? Yes. Page 4