Slides

advertisement

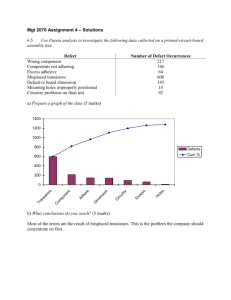

An Introduction to Statistical Process Control Charts (SPC) Steve Harrison Monday 15th July 2013 12 – 1pm Room 6 R Floor RHH Topics • Variation – A Quick Recap • An introduction to SPC Charts • Interpretation • Quiz • Application in Improvement work Variation Common Cause Variation • Typically due to a large number of small sources of variation • Example: Variation in work commute due to traffic lights, pedestrian traffic, parking issues • Usually requires a deep understanding of the process to minimise the variation 5 Special Cause Variation • Are not part of the normal process. Arises from special circumstances • Example: Variation in work commute impacted by flat tire, road closure, ice-storm. • Usually best uncovered when monitoring data in real time (or close to that) 6 Special Cause - My trip to work 120 Upper process limit 100 Mean 80 Lower process limit Min. 60 40 20 0 Consecutive trips Two Types of Variation Common Cause: • chance cause • noise Special Cause: •assignable cause •signal Statistically significant (not good or bad) 8 SPC Charts 9 SPC, Statistical Process Control or The Control Chart Elements 1. Chart/graph showing data, running record, time order sequence 2. A line showing the mean 3. 2 lines showing the upper and lower process ‘control’ limits •You only need 25 data points to set up a control chart, but 50 are better if available The Anatomy of an SPC or Control Chart 80 Upper process control limit 70 60 Mean 50 40 Lower process control limit 30 20 10 0 F M A M J J A S O N D J F M A M J J A S O N D Measures of Central Tendency •Mean = Average – SPC Chart •Median = Central or Middle Value – Run Chart •Mode = Most frequently occurring value 12 Standard Deviation or σ In statistics, standard deviation shows how much variation exists from the mean. A low standard deviation indicates that the data points tend to be very close to the mean; high standard deviation indicates that the data points are spread out over a large range of values. Standard Deviation and a normal distribution PRACTICAL INTERPRETATION OF THE STANDARD DEVIATION 99.6% will be within 3 s Mean - 3s Mean 0.4% will be outside 6s in a normal distribution Mean + 3s 3s AND THE CONTROL CHART UCL 3s 3s 6s Mean LCL Run Charts vs. SPC Charts Run Chart • Simple SPC • More Powerful • Easy to create in Excel • Control lines show the degree of variation • Less Sensitive • Need Special Software • Only need 10 data points • Need 25+ data points Ward x – % of total TTOs completed by 12 noon April 4 - May 15, 2012 70 60 50 40 30 20 10 17 15-May 13-May 11-May 9-May 5-May 3-May 22-Apr 20-Apr 18-Apr 14-Apr 12-Apr 8-Apr 6-Apr 0 4-Apr % Daily TTOs Completed by Noon 80 Special cause variation 90 80 70 60 50 40 30 20 10 0 F M A M J J A S O N D J F M A M J J A S O N D SPECIAL CAUSES - RULE 1 UCL Point above Upper Control Limit (UCL) MEAN LCL SPECIAL CAUSES - RULE 1 UCL MEAN LCL Or point below Lower Control Limit (LCL) SPECIAL CAUSES - RULE 2 UCL MEAN LCL Eight points above centre line A 1 in 256 chance or 0.3906% SPECIAL CAUSES - RULE 2 UCL Or eight points below centre line MEAN LCL A 1 in 256 chance or 0.3906% SPECIAL CAUSES - RULE 3 UCL Six points in a downward direction MEAN LCL SPECIAL CAUSES - RULE 3 UCL Or six points in an upward direction MEAN LCL SPECIAL CAUSES - RULE 4 UCL Considerably less than 2/3 of all the points fall in this zone MEAN LCL SPECIAL CAUSES - RULE 4 UCL Or considerably more than 2/3 of all the points fall in this zone MEAN LCL Quiz – 1. Does the chart show A. Special Cause Variation? B. Common Cause Variation? C. Both of the above D. No Variation 100% nt io e ria Va No he of t 0% t io n 0% ab ov n tio ia na l Va r ria Va In te Ca us e on Al l tio ia Va r se Co m m lC au cia Sp e 0% t io n? n? 0% 2. How many special cause signals are present on this chart? A. 0 B. 1 C. 2 D. 3 E. 16 90% 0% 0% 16 2 1 0 0% 3 10% 3. How many special cause signals are present on this chart? A. 0 B. 1 C. 2 D. 3 E. 16 90% 0% 0% 16 2 1 0 0% 3 10% 4. How many special cause signals are present on this chart? A. 0 B. 1 C. 2 D. 3 E. 16 70% 20% 10% 16 3 2 0% 1 0 0% What use is this? • Evaluate and improve underlying process • Is the process stable? • Use data to make predictions and help planning • Recognise variation • Prove/disprove assumptions and (mis)conceptions • Help drive improvement – identify statistically significant change Example Annotated SPC Charts •One of the most powerful tools for improvement •Describe a process captured over time (as opposed to being a single sample) •Reveal any trends a process might be experiencing •When combined with careful annotation they track the impact of change Why We Want to Annotate Our Charts… 'And this is the period when the cat was away. ' Example – Renal DT247J PDSA 1 PDSA 2 Application – Responding to Variation 36 Responding to Special Cause Variation •Identify the cause: • If positive then can it be replicated or standardised. • If negative then cause needs to be eliminated 37 Responding to Common Cause Variation 1. Reduce variation: make the process even more predictable or reliable (and/or) 2. Not satisfied with result: redesign process to get a better result 38 Process with special cause variation Process with common cause variation Identify the cause: if positive then can it be replicated or standardized. If negative then cause needs to be eliminated Reduce variation: make the process even more reliable Not satisfied with result: redesign process to get a better result 39 DISCUSSION Evaluation 1. Absolute Rubbish 2. Terrible 3. Fairly Bad 4. Not that Great 5. Alright 6. Quite Good 7. Really Quite Good 8. Very Good 9. Excellent 10. Amazing! 50% 40% 10% 41 0% 0% 0% 0% 0% 0% Te rr Fa ible N o ir l tt yB h a ad tG re a Al t Re Qu rig h al i ly te G t Qu o ite od G Ve oo ry d Go Ex o d ce ll Am ent az in g! Ab so lu te Ru bb i sh 0% THANKS! 2 1 4 3 45