Document

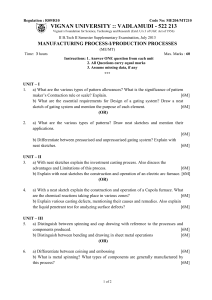

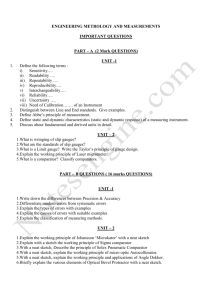

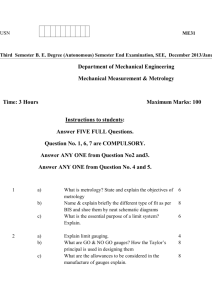

advertisement

No: R22034 SET - 1 R10 II B. Tech II Semester Supplementary Examinations January - 2014 PRODUCTION TECHNOLOGY (Mechanical Engineering) Time: 3 hours Max. Marks: 75 Answer any FIVE Questions All Questions carry Equal Marks ~~~~~~~~~~~~~~~~~~~~~~~~ 1. a) Explain different types of patterns with neat sketches. b) What are the advantages casting? 2. a) What is the function of a riser? Write note on the shape and size of risers. b) Explain the steel making processes. 3. a) How do you classify the welding processes? b) Explain 'Thermit Welding' process with a neat sketch. 4. a) Explain the term HAZ in welding and its role in the success of a weldment. b) Bring out the difference between TIG and MIG welding processes. 5. a) Distinguish between Hot rolling and Cold rolling. b) What is strain hardening? Explain in detail. 6. a) How do you classify presses? Explain them briefly. b) Briefly explain the metal spinning operation. 7. a) Explain briefly the Open-die forging and Impression die forging. b) State the advantages and disadvantages of forging. 8. a) How do the thermoplastics differ from thermo-setting plastics? b) With the help of neat sketch explain the processing of plastics by compression moulding method. 1 of 1 ||'''|''|''||''|'''| SET - 2 R10 Code No: R22034 II B. Tech II Semester Supplementary Examinations January - 2014 PRODUCTION TECHNOLOGY (Mechanical Engineering) Time: 3 hours Max. Marks: 75 Answer any FIVE Questions All Questions carry Equal Marks ~~~~~~~~~~~~~~~~~~~~~~~~ 1. a) Explain using a simple sketch the layout of a typical foundry. b) Explain the sequence of steps involved in casting. 2. a) What is the difference between the solidification of pure metals and metal alloys? Explain b) Describe the Centrifugal casting process and its applications. 3. a) Describe the gas welding process with neat diagram. b) Sketch and explain various welding positions? Give their applications. 4. a) Explain briefly the welding defects. b) How is Brazing different from Welding and Soldering? 5. a) Explain the terms 'Recovery', 'Recrystallisation' and 'Grain growth'. b) Compare the properties of cold worked and hot worked parts with examples. 6. Describe the following: i) Blanking ii) Deep drawing and iii) Spinning processes. 7. a) What is Extrusion? List the advantages, limitations and applications of Extrusion process. b) Discuss hydrostatic extrusion process with a neat sketch 8. a) Write brief note on properties of plastics and types of plastics. b) Describe with a neat sketch the processing of plastics using injection moulding method. 1 of 1 ||'''|''|''||''|'''| R10 Code No: R22034 SET - 3 II B. Tech II Semester Supplementary Examinations January - 2014 PRODUCTION TECHNOLOGY (Mechanical Engineering) Time: 3 hours Max. Marks: 75 Answer any FIVE Questions All Questions carry Equal Marks ~~~~~~~~~~~~~~~~~~~~~~~~ 1. a) Show the components of a gating system with a diagram and explain them in detail. b) Briefly explain the various types of allowances provided in patterns. 2. a) What steps are involved in the preparation of a Casting? Explain briefly the die casting process. b) Explain the two types of crucible furnaces with diagrams. 3. a) What are the basic requirements of welding? Explain. b) Sketch and explain the submerged arc welding. 4. a) Differentiate between destructive and non-destructive testing of Welds. b) Explain the following: i) Friction welding and 5. ii) Laser welding. a) Explain hot rolling operations through: i) Two high ii) Three high and b) How do you estimate rolling load? iii) Four high rolling mill 6. Explain briefly the following processes: a) Tube drawing b) Embossing. 7. a) Briefly describe the Drop forging and Machine forging processes. b) Explain the various defects in forging. 8. a) What are the advantages and limitations of plastics? b) Differentiate between injection moulding and extrusion moulding. 1 of 1 ||'''|''|''||''|'''| Code No: R22034 1 of 1 SET - 4 R10 II B. Tech II Semester Supplementary Examinations January - 2014 PRODUCTION TECHNOLOGY (Mechanical Engineering) Time: 3 hours Max. Marks: 75 Answer any FIVE Questions All Questions carry Equal Marks ~~~~~~~~~~~~~~~~~~~~~~~~ 1. a) Why casting is preferred over other methods of manufacturing? Discuss. b) Define gating ratio and write a brief note on the design of gating system. 2. a) Explain briefly the Investment casting and Die casting. b) With the help of a neat sketch explain the construction and working of Cupola Furnace. 3. a) Explain the principle involved in resistance welding with a neat sketch. b) Explain briefly the Oxyacetylene cutting process. 4. a) What are the essential steps in Brazing? Explain why it is suitable for joining dissimilar metals? b) Discuss electron beam welding with its advantages. 5. a) Enumerate the typical applications of Cold working. b) Write a note on thread rolling process. c) What are the forces and power requirements in rolling process? 6. a) Explain with a neat sketch 'wire drawing' process. b) Briefly describe Deep drawing and Stretch forming processes. 7. a) With the help of neat sketches explain briefly the various Cold Extrusion processes. b) Briefly describes the Extrusion defects. 8. a) Distinguish between thermosetting plastics and thermoplastics. Give their applications. b) Describe with a neat sketch the processing of plastics using Blow moulding method.