Manufacturing Technology

advertisement

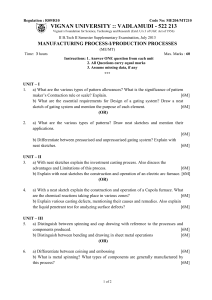

SUB 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 24. 25. 26. 27. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. QUESTION BANK : MANUFACTURING TECHNOLOGY - I ( ANNA UNIVERSITY CODE :ME 6302) -R 2013 UNIT - I ( METAL CASTING PROCESSES) PART - A ( 2 Mark questions ) What is meant by Grain fineness number ? (AU 2014) Mention few applications of Centrifugal casting. (AU2014) What is meant by core print ? (AU 2012, 2008) Name the different melting furnaces employed for metal casting. (AU2012) State any four types of patterns. (AU2012) What are the causes for the formation of blow holes in sand casting ? (AU2012) Mention the different terms by which moulding flask is referred to in three piece moulding. (AU2009) Give the merits and demerits of Aluminium and steel pattern materials. (AU2009) Name the materials used for making patterns. (MQ) Compare the advantages of metal moulds over sand moulds. (AU 2013 ) What are the functions of flux in melting metals and alloys ? (AU 2013) State the essential properties of moulding sand. (AU2005) Give any two merits and demerits of investment casting process. (AU2005) Mention any two merits and demerits of die casting. (AU2006) Write the requirements of a good pattern. (AU2007) What is core venting ? (AU2007) What are the ingredients of core sand ? (AU2008) Differentiate the terms ‘mould’ and ‘core’ . (AU2008) What are the advantages and applications of ceramic moulds ? (AU2008) What is the function of core ? (AU2008) Which process is called “Lost wax process”? Why ? (AU2008) What is the difference between a pattern and a casting ? (AU2010) What is Fettling ? (AU2009) Why is a pattern larger than the casting ? (MQ) What are the reasons for providing pattern allowances ? (MQ) Define permeability number. (MQ) PART - B ( 16 MARKS ) What are the allowances given while making pattern ? Explain . (AU2013, 2012) Describe the process of Investment casting. What process controls are needed in this case ? (AU2013) Briefly explain the principle, operation, advantages, disadvantages and applications of CO2 moulding . (AU2013) Describe, with a neat sketch, cold chamber die casting machine. Give its advantages and Limitations. (AU2013) How are castings defects classified ? Enumerate the procedure of testing castings by X-ray radiography. (AU2010) What are the desirable properties of mould sand for sand casting ? Explain briefly each one. (AU2014, AU2012, 2008)) With illustrative sketches, explain the various casting defects indicating their causes and remedies. (AU2012, 2008) Explain the stages of preparing Shell mould, with suitable sketches. List the unique advantages of making castings in shell moulds. (AU2012) Explain the various steps involved in ‘Lost wax process’ with suitable sketches.(2012) Write short notes on (i) Ceramic mould and (ii) Centrifugal casting. (AU2012) Explain with neat sketch the working of cupola furnace. (AU2009) 12. 13. 14. 15. 16. 17. 18. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 25. 1. 2. 3. 4. Explain the Hot chamber die casting process with suitable sketches. (AU2009, 2008) What are the common materials used for pattern making ? Discuss their relative merits and demerits. (AU2010) Describe the procedure of making castings by Centrifugal casting process. (AU2010) Briefly explain the different methods for inspection of castings. (AU2008) Briefly explain (i) Match plate pattern and (ii) Gated patern (AU2007) Briefly explain the working of Cupola furnace. (AU2014) Explain the various steps involved in sand core manufacturing. (AU 2014) UNIT - II ( JOINING PROCESSES) PART - A ( 2 Mark questions ) What is the minimum distance maintained between two successive spot welds made by resistance welding ? Why ? (AU 2013) Write short notes on transferred arc in Plasma arc welding. (AU2013) What is meant by “Carburising flame” in gas welding ? (AU2012) What is the principle of Thermit welding ? (AU2012) What are the functions of flux in welding electrodes ? (AU2012) What are the types of adhesives used in adhesive bonding ? (AU2012) Define the term ‘electrode’ and mention its major classification. (AU2011) What is brazing ? (AU2011) What are the advantages of AC equipment over DC equipment in arc welding.(AU2010) Differentiate Fission welding from Fusion welding. (AU2010) Why is flux used in soldering and brazing ? (AU2010) Mention the applications of Friction welding . (AU2010) What is the application of Carburising flame ? (AU2009) What are the diameter and length of the electrodes available in the market ?(2009) What is the purpose of flux ? (AU2008) How can slag inclusions in welding be avoided ? (AU2008) How does brazing differ from braze welding ? (AU2008) Why is flux coated on filler rods ? (AU2008) What are the special features of friction welding ? (AU2007) Define resistance welding process. (AU2007) What is the disadvantage of flux ? (MQ) What are the factors affecting resistance welding ? (MQ) Name the types of resistance welding. (MQ) What is meant by Nugget in Electric Resistance welding ? (AU2014) What are the functions of flux used in welding electrodes? (AU2014) PART - B ( 16 MARK QUESTIONS ) Explain the principle of friction welding, its advantages and disadvantages. (AU2014) (a) What are the non destructive tests used in Welding Inspection ? Explain any one method. (b) Explain with a neat sketch the Equipment and process of Sub merged arc welding. (AU2011,2013) (a) Discuss the gas welding process and the necessary equipments needed with suitable sketches. (b) Explain the metal arc welding process with a neat sketch. (AU2012) (a) Explain the plasma arc welding process with a neat sketch and list out its advantages. (AU2011,12) (b) Sketch the different types of weld defects and mention how they occur. (AU2012, 2010)) 5. 6. 7. 8. 9. 10. 11. 12. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. (a) With the help of suitable diagrams, explain the following types of welding : (i) TIG welding process , (ii) Electro slag welding process (AU 2014, 2012) (a) What is the principle of Thermit welding ? Explain the same with a neat sketch of the welding arrangement. (b) Explain the principle of operation, advantages and limitations of Electron Beam Welding. (AU 2014, 2012) Sketch the three types of flames in Oxy-Acetylene welding and state its characteristics. (AU2014, AU2011) List out the different types of welding process. Briefly explain the working principle of any two welding process. (AU2010) (a) Describe with a neat sketch the components of Oxy-Acetylene gas welding equipments. (AU2010) (b) Discuss the principle of Adhesive bonding. List out any four types of adhesives. (a) Describe with neat sketches various steps in friction welding. (b) Describe with a neat sketch the principle of percussion welding. State its advantages and limitations. (AU2010) (a) Discuss the filler and flux materials used in Arc welding process. (b) Discuss the types of flames in Gas welding. (AU2009) (a) Explain the TIG and MIG welding process with their applications. (b) Explain the resisitance welding process giving the equipment, parameters controlled and the applications. (AU2009) UNIT III (METAL FORMING PROCESSES ) PART – A ( 2 MARKS ) What is meant by fullering ? (AU2013) Working on the metal lead at room temperature, is considered to be hot working. Why ? (AU2012) List two advantages of cold extrusion over hot extrusion. (AU2012) Distinguish between hot working and cold working of metals. (AU2012) Define Extrusion, as a manufacturing process. (AU2012, 2009)) Distinguish between Open die forging and Closed die forging. (AU2011) Define the term : Extrusion ratio. (AU2011) What is meant by closed die forging ? (AU2010) Mention the different types of shape rolling operation. (AU2010) What is meant by recrystallisation temperature ? (AU2010) List out any four parts that can be manufactured by shape rolling operations.(AU2010) What are the disadvantages of forging process ? (AU2009) Why are a number of passes required to roll a steel bar ? (AU2008) What is Sejournet process ? (AU2008) What is skew rolling ? (AU2008) What is impact extrusion? (AU2007) What is the difference between a bloom and a billet ? (AU2007) What are the four major drawbacuireds of hot working ? (AU2006) Classify the types of extrusion. (AU2006) How are seamless tubes are produced ? (AU2006) Why is drop forging called so ? (AU2014) What does angle of bite in rolling mean ? (AU2014) 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. PART – B ( 16 MARKS ) (a) Briefly explain about seamless rolled ring forging. (b)Briefly explain flat strip rolling operation. (AU2013) (a) Explain Hot working and Cold working forging operations with their advantages and limitations. (b) Explain with a neat sketch the process of wire drawing. (AU2013, 2014) With neat sketches, explain the following smith forging operations : (a)Upsetting, (b) Bending, (c) Swaging, (d)Fullering, (e)Punching and drifting and (f)Edging. (AU2012) With suitable sketches, explain the following : (a) Stages involved in ‘shape rolling’ of structural sections. (b) Cold extrusion forging (c) Seamless tube drawing. (AU2012) (a) Explain, with a neat sketch, the working of Pnuematic hammer for forging. (b) List four tools used in forging. Sketch any two of them. (AU2012) Explain, with neat sketches , the different types of roll stand arrangements used in Rolling mill and state their purpose. (AU2012, 2011) Distinguish between forging hammers and forging presses. Explain the working of Drop hammer with a neat sketch. (AU2011) (a) What are the defects in parts produced by rolling ? Explain any four defects. (b) Distinguish between wire drawing and tube drawing with sketches. (AU2010,2009) How do you compare forged components with cast components ? (AU2009) Explain with a neat sketch (i) Direct and Indirect Extrusion and (ii)Rolling process. (AU2014) UNIT – IV ( SHEET METAL PROCESSES ) PART- A ( 2 MARKS ) What is ironing, as applied to sheet metal work ? (AU2013,2011) What is the spring back effect in sheet metal component ? (AU2013, 2012) Why is it necessary to provide proper clearance between the punch and die in shearing operation ? (AU2013) What is “Lancing” operation that is done on sheet metals. (AU2012) What are the limitations of Explosive forming ? (AU2012) What are the advantages of hydro forming process ? (AU2012, 2009) What are the advantages of Rubber pad forming process ? (AU2011) Define the term “Formability”. (AU2010) Define : Peen forming (AU2010) What are the applications of Peen forming ? (AU2010) Define “embossing”. (Au2009) Define degree of polymerization. (AU2009) What is the rotational moulding of plastics ? (AU2009) What do you mean by minimum bend radius ? (AU2008) How is hydro forming is similar to rubber forming ? (AU2008) Give the difference between punching and blanking. (AU2008) Define Hydro forming process. (AU2007) What is press brake ? (AU2007) What is super plastic forming process ? (AU2006) Define limiting drawing ratio. (AU2006,2008) What is shear angle ? Why is it given in punches and Dies ? (AU2014) What is flanging ? (AU2014) 1. 2. 3. 4. 5. 6. 7. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. 21. 22. PART – B ( 16 MARKS ) (a) Explain the basic nomenclature of tube bending with a simple sketch. (b) Discuss super plastic forming with necessary sketches. (AU2014) (a)Explain with a neat sketch the principle and operation of magnetic pulse forming. (b) What are the different types of stretch forming ? Explain any one. (AU2013,2014) Sketch and explain the following sheet metal bending operations : (a) sheet bending using V Die (b) Bending edge of a sheet using wiping- die (c) Roll bending (d) Bending a sheet to a round shape using four slide machine. (AU2012) (a) With a neat diagram, explain the principle of explosive forming. (b) Explain the Hydro forming process with neat sketches. Compare this processs with conventional deep drawing . (AU2012, 2011) (a) with a neat sketch, explain the rubber pad forming process. How does it differ from rubber hydro forming process ? (AU2014) (b) Describe the metal spinning process with a neat sketch. State its advantages and specific uses. (AU2012, 2011,2009) (a) Distinguish between blanking and punching operations. Sketch and explain the elastic phase, plastic phase and fracture phase that take place in a blanking operation. (b) Briefly explain what are compound dies and progressive dies, with suitable sketches. (AU2011) (a) Write a note on sheet metal characteristics. (b) Describe the shearing and bending operations with suitable examples. (AU2010) UNIT – V (MANUFACTURING OF PLASTIC COMPONENTS ) PART – A ( 2 MARKS ) What is polymerization? (AU2013) What is calendaring in processing of plastics ? (AU2013) Name two important differences between thermoplastics and thermosetting plastics. (AU2012) What is film blowing ? (AU2012, 2007)) Name two adhesives that are used for adhesive bonding process. (AU2012) What are the advantages of Transfer moulding ? (AU2011) Write a note on Thermoplastics. (AU2010) List the application of Transfer moulding. (AU2010) Write the principle of Thermoforming. (AU2010) What is rotational moulding of plastics ? (AU2009) Define Degree of polymerization. (AU2009) What is parison ? (Au2008) Name the parts made by rotational moulding . (AU2008) What is compression moulding ? (AU2008) What are the types of plastics ? (AU2007) List the advantages of cold forming of plastics. (AU2007) List out the materials for processing of plastics. (AU2006) What are the characteristics of Thermoplastics ? (AU2006) Define Plasticizers. (MQ) What are the major considerations in the design of plastic parts ? (MQ) What is polymerization ? (AU2014) List out any four adhesive used in adhesive bonding of plastics. (AU2014) 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. PART – B ( 16 MARKS ) (a) What is rotational moulding ? State its advantages and limitations. (b)Explain briefly any two bonding methods of thermoplastics. (AU2013, 2014) Explain briefly with neat sketches two commercially used methods of blow moulding for blowing of plastic bottles and mention their specific advantages. (AU2013) (a) Describe briefly the plunger type injection moulding process for producing plastic components. (b) Explain, with neat sketches, the thermo forming process. State its advantages over other processes. (AU2012) (a) with neat sketches, explain Compression moulding and Transfer moulding processes. (AU2012) Describe briefly the screw type injection moulding process for producing plastic components. (AU2012, 2010) Briefly explain the following methods of bonding of Thermoplastics : (AU2011) (a)Fusion bonding, (b) Vibration bonding, (c) Solvent bonding and (d)Induction welding. (a) Explain the application of Injection moulding. (b) Write down the characteristics of shaping processes for plastics. (AU2010) Discuss the various properties of plastics. (AU2009) Describe briefly about Transfer Moulding . State its Advantages and Limitations . (AU2014) With neat sketches , briefly explain Positive, Semi positive and Flash type compression Moulding. (AU2014)