What is Wood used for at the moment

advertisement

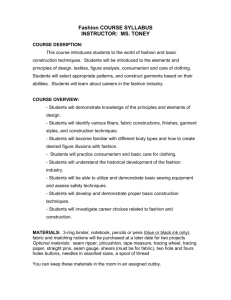

FEASIBILITY STUDY A feasibility study for WOOD FASHION Technology Project Date: 24/08/2010 By: Catharina Eden Ltd INDEX PROJECT SCOPE .................................................................................................................................................................... 3 CURRENT ANALYSIS ....................................................................................................................................................... 4-12 CURRENT FASHION TRENDS ...................................................................................................................................... 13-15 REQUIREMENTS .................................................................................................................................................................. 16 POTENTIAL MARKET ................................................................................................................................................... 16-17 RESEARCH AND DEVELOPMENT ................................................................................................................................... 18 CONCLUSION ........................................................................................................................................................................ 18 APPENDICES .................................................................................................................................................................... 19-20 Project Scope The Flexible Wood Technology Project (Eden Wood) is Finland based and aimed at researching the possibilities of developing and producing sustainable and environmentally friendly fabric using Finnish wood as its core composition. Students from three leading universities (Lahti, Mikkeli and Lappeenranta) will jointly carry out the work, lead by professors from each university. The universities will collectively study wood fibres physical and chemical properties as well as mechanical properties of untreated and treated fibres. They will attempt to explore and expand the possibilities wood is suitable for and to find out whether modern polymerisation processes such as mechanized defibreing, classification, refinement processing, softening, cottonization, spooling and finally fabric manufacture are available for wood. The possibility of making wood flexible by manipulating its natural properties will also be explored. The research and development work will be carried out with the joint collaboration between Mikkeli Technology Centre Ltd (Miktech),The Centre of Expertise Programme (OSKE), Lappeenranta University of Technology and Lahti University. The majority of the work, however, will be done at Lappeenranta University. Miktech supports development activities in research institutes and in enterprises. Miktech concentrates on exploitation of new technologies and inventions. Miktech is an activator for new inventions and it promotes technology-based businesses. Lappeenranta University’s areas of strength include energy efficiency and a long-standing relationship with the Finnish forest industries. They also have a cluster called Forest Industry Futurem which objective is to find new solutions for forest industry and to accelerate the growth of especially sm-enterprises and to speed up the regeneration of the field. Oske combines high-level research and diverse innovative activities with the necessary technology, design and business competence. The programme is a tool for regional innovation, which contains ready-made operating models and networks for the national and international markets. Catharina Eden will play a management role expanding understanding of the possibilities of new wood technologies being used in the fashion sector. Catharina will be using her experience of the cutting edge fashion, being the founder of her own label and one of the few Finns working in the international high fashion, to bring the project to life and take it to the international market. Catharina is also a passionate and active believer in sustainable fashion; one of the key drivers of the Eden Wood -project. Current Analysis Similar products currently in the market TENCEL® is the brand name owned by Lenzing Fibers of Austria for a recently improved fabric from a fiber generically called lyocell. Lyocell is made from cellulose found in wood pulp which has been harvested from tree farms. Cellulose is the natural polymer that makes up the living cells of all vegetation. The fiber is produced via an advanced 'closed loop' solvent spinning process, with minimal impact on the environment and economical use of energy and water. Lyocell uses an amine oxide as a non-toxic solvent which is continually recycled during the production process. Production plant emissions into the air from smokestacks and from wastewater are significantly lower in comparison to many other man-made fiber operations. Tencel won the European Union Environmental Award 2000 for "technology for sustainable development". Despite its green credentials though, some of the it’s goodness is lost in the manufacturing process as it uses a lot of harmful chemicals when dyed and finished. Tencel is now used in the company’s own branded bedding linens, covers and mattresses and is increasingly used in clothing too with H&M being the latest brand to adopt it in its range. More about Tencel’s technical properties in the appendices. H&M Summer 2010 Lenpur Lenpur is a textile fibre from cellulose from a variety of trees including pine trees. The main differences in Lenpur compared to other cellulose fibres is its softness, its moisture absorption capacity, its ability to release dampness (as a yarn or fabric), its deodorant properties, and its adsorption characteristics (due to its morphology). When mixed with other fibres, Lenpur is in "mechanical synergy" with them. Lenpur is mainly used in underwear and in women’s stockings. It is also used as yarns. More about the techncal properties of Lenpur in the appendices Feuille/Abeflex Intended for the furnishing, automobile, interior decoration, fashion accessories and packaging industries. Albeflex sheets are flexible wood claddings that are defibrated and sanded down before being stuck onto leather or imitation leather, thereby allowing them to be sewn. This material is not used in the fashion industry as it is too hard to be worn or made into intricate details. It has, however been adopted in the accessories industry in handbags and shoe heels. Bark Cloth It is made by beating sodden strips of fibrous inner bark of the Mutuba trees into sheets, which are then finished into a variety of items. This is a decorative textile and is mainly used in African countries and in traditional clothing. Bark Cloth is also used in Western countries in the interior as wall coverings, furnishing, the automobile and sailing industries. All in all there are very few clothing textile products from wood in the market at the moment. The majority of the current offerings are more suitable to the interior world than for textiles. However, the interest towards sustainable and eco fabrics in general is tremendous and the supply to support such interest is not there. The few fabrics that are on offer at the moment is just a drop in the ocean and more can be added to the market with relative ease. Natural sources such as cotton, silkworm and sheep have offered relatively easy and manageable fibres for refinement. New additions to the opened natural fibre market (not in history though) include hemp, jute, kenaf flax, ramie and most notably bamboo (listed below). Wood, however, is seen as a harder fibre to tackle. In addition to this, man-made fibres such as acetate and polyester have saturated the desire for cheap fabric for the masses and hence advances in natural fibre technology have not been in a high demand. Today, however, man-made fibres are slowly becoming less popular and natural fibres, produced in a sustainable way, are in return becoming more sought after. This is partly due to the textile supply chain reacting to their consumer being more aware of local and global impacts of their fabrics produced in an environmentally aware way, but also because the cultivation and refinement methods have advanced to the point where the producers can offer more competitive pricing than before. This means that garments made from natural fabric sources are more accessible to the average consumer. Properties such as softness, durability and colourfastness have also been improved, which makes garments made from these fabrics more wearable than before and equal or even surpassing their man-made counter parts. In addition to the technological advances in material innovations, the fashion industry is also playing it’s vital part as fashion design is all about creativity and resourcefulness, pushing its creativity to new horizons. Livia Firth’s (actor Colin Firth’s wife) open and genuine support for designers with eco credentials is widely supported and her actions are applauded in the fashion industry as is Stella Mc Cartney’s stand on all aspects of sustainable sourcing and manufacturing. Both high profile ladies, to name just a few, serve as prime examples on how fashion is ready and receptive for innovations in sustainability. Overview of other bast fibres currently available Bamboo Bamboo has had the most success among all the new "eco-textiles" on store shelves—fabric billed as environmentally friendly and made from materials such as soybeans, corn, milk, seaweed and recycled plastic. Bamboo shows up in clothes sold in Nordstrom and Saks Fifth Avenue, as well as sheets sold at Target, and it bears such deluxe labels as Ermenegildo Zegna, Rag & Bone and Ralph Lauren, as well as more eco-focused brands. Because it is so exotically soft, bamboo is often marketed alongside luxury fibers like silk and cashmere. Bamboo's story sounds clear and appealing: like hemp, the plant grows quickly without the irrigation, pesticides or fertilizer often used to grow cotton. It's often sold as "biodegradable," and the plant's antimicrobial properties have been used to market athletic clothes made from the fiber. "People are switching from cotton to bamboo," says Aarti Doshi, regional manager for bamboo-fabric distributor Doshi Group, based in Mumbai, India. However, when looked below the surface bamboo fabric is less "eco" and "sustainable" than it seems. The bamboo used in textiles has to be heavily manipulated to go from stem to store. To create fabric, it's chopped up and dissolved in toxic solvents—the same process that recycles wood scraps into viscose or rayon. Indeed, bamboo fabric technically is rayon. Sameunderneath Summer 2010 Catharina Eden Spring Summer 2008 Hemp Hemp is used for a wide variety of purposes, including the manufacture of cordage of varying tensile strength, clothing, and also nutritional products. Hemp can be used as the sole composition, but is commonly blended with other organic fibres such as flax, cotton or silk, for apparel and furnishings, most commonly at a 55%/45% hemp/cotton blend. This fiber is not favoured mainly due to its coarse texture. The luxury brand Virdis Luxe, however, endorsed by actresses Uma Thurman and Laura Dern, makes desirable clothing using hemp and the trend can only be predicted to grow even more popular. Virdis Luxe Jute Jute can be used to create a number of fabrics, but the most commonly known are Hessian cloth, which is used for bags, wrappers, wall-coverings, upholstery, and home furnishings, and Sacking. The latter is used as sacking for its heavy duty properties. Diversified jute products are becoming more and more valuable to the consumer today. Among these are floor coverings, home textiles, high performance technical textiles, Geotextiles, composites, and more. Hessian cloth has been used from time to time in fashion with varying results. Most recently in Calvin Klein resort collection, which received very poor reviews. Calvin Klein Resort 2010 Kenaf This bast plants stems produce two types of fibre, a coarser fibre in the outer layer, and a finer fibre in the core. It matures in 100 to 200 days. The main uses of kenaf fibre have been rope, twine, coarse cloth (similar to that made from jute), and paper. There are many other uses of kenaf fibre such as insulation, cloth, soil-less potting mixes, animal bedding, packing material, but none relating to the clothing industry. No evidence of Kenaf being used in fashion was found. Ramie This is one of the strongest natural fibres and exhibits even greater strength when wet. Ramie fibre is known especially for its ability to hold shape, reduce wrinkling, and introduce a silky lustre to the fabric appearance. It is not as durable as other fibres, and so is usually used as a blend with other fibres such as cotton, linen or wool. It is similar to flax in absorbency, density and microscopic appearance. However it will not dye as well as cotton. Because of its high molecular crystallinity, ramie is stiff and brittle and will break if folded repeatedly in the same place; it lacks resiliency and is low in elasticity and elongation potential. Despite its strength, ramie has had limited acceptance for textile use. The fibre's extraction and cleaning are expensive, chiefly because of the several steps—involving scraping, pounding, heating, washing and exposure to chemicals. Korean ramie showcase Flax / Linen Flax is stronger than cotton fiber but less elastic. The best grades are used for linen fabrics such as damasks, lace and sheeting. Coarser grades are used for the manufacturing of twine and rope. Flax fiber is also a raw material for the high-quality paper industry for the use of printed banknotes and rolling paper for cigarettes and tea bags. Some fashion designers are of the opinion that, unlike other fibre materials, the beauty of linen lies in its unique quality to crush. The outcome of crushes gives an exclusive look to linen, even when worn formally. The cloth mills are making linen from colours ranging from creamy white to light brown; dying linen is easy and does not fade after washing. Presently, trousers, dresses, shirts are being made by linen. Interesting cuts, well-defined edges, frills, handpainting, delicate embroidery and machine work can further highlight the look of the fabric. The variety and uses of linen have gone broader in fashion industry. It has become daily-wear fabric; it has come a long way with cotton-mix, poly-mix and lycra blend. Linen is, no doubt, ruling the market. Another distinct quality of linen is that dresses made out of it blend very well with accessories of other materials. The different types of linen available in the market further broaden the chances of experimentation. Fashion designers usually prefer Egyptian, Japanese and the wrinkle-free poly- mixed Egyptian linen. Irish linen is prized for its fine white colour as it is the colour of summer. Scottish linen is lighter in colour than Irish linen, but it is an extraordinary summer choice. French linen is differentiated by fine designs, ranks high on the summer calendars. All mentioned types of linen are ideal for every type of garment. When it comes to colours, beige and white are the best choices for linen dresses. Orange, tangerine and fuchsia are also used by fashion experts to make a personalized statement. Another aspect of this fabric is that it has somehow still maintained itself as a symbol of style, elegance and comfort. Lundstrom 2010 Hoss Intropia Summer 2010 Abaca Abaca fibres is widely known as Manilla or Manila Hemp and is known to be the strongest fibre existing. It is made of Abaca leaf heath which physically appears beneath the bark of a type of banana tree. Indigenous tribes people such as the T’boli in the Philippines have made fabric from Abaka for many generations using very basic and traditional methods. Today it’s use has been refined and made into modern fabrics used across the furnishing and clothing worlds. It can also be blended with other fibres such as cotton and silk. Doo-Ri 2009 Current Fashion Trends The world is changing, and as ever, fashion follows. In my profession I make one off evening garments and wedding dresses, but I also run the UK’s first garment sampling and small production unit that has been based on environmentally and socially aware principals. In Eden Studio, the sewing unit, I meet a very broad spectrum of UK based designers everyday and am thus in the centre of gaining knowledge on what designers are looking for and need. Current trends are picked up very quickly and thoughts are transferred into the coming trends of the future. More and more designers are talking to me about eco-friendly fabrics and having difficulty with the supply and choice. As and average at the moment 30% of designers with me use a variety of sustainable eco fabrics, mainly bamboo and blends of bamboo, but more importantly the rest would seriously consider. In the UK alone there are countless individual designers, either just starting out or more established, who only use 100% certified sustainable/ eco fabrics. Esthetica, the initiative by British Fashion Council is the environmental wing of London Fashion Week and will now be in it’s seventh season. Another example is the large ethical section of Pure, the bi annual trade exhibition in London that is even bigger in market sale power than LFW. Websites such as Ethical Fashion Forum and Eco Fashion World as well as the Center for Sustainable Fashion in London College of Fashion combined have thousands of new designers as members, all sharing the same eco values. These designers are shaping the future of our fashion and with their growing rate it is an inevitable truth that non-harmful fabrics will be the most popular choice. A few years back a ground breaking “Earth Pleadge FutureFashion” show was held in New York in August 2008, where Givenhy, Ralph Lauren and Versace came together with designers such as Diane Von Furstenberg, Stella McCartney, Donna Karan, Michael Kors, Jill Sanders and Narciso Rodriques to kick off Fashion Week. Organized by Earth Pleadge, the show was a one of a kind event displaying sustainable fabrics and organically grown, natural fibres such as hemp, abaca, silk and wool as well as new materials such as bio-plastics and man made cellulosics. “ These materials are all selected because the reduce harmfull chemical and energy use, and protect land resources for future generations,” Leslie Hoffman, Earth Pledge’s executive director. The event was sponsored by Barneys New York and Lexus Hybrid. Rodarte, for Earth Pledge FutureFashion 2008 Rogan, for Earth Pledge FutureFashion 2008 Back in the UK, the Financial Times, a highly revered newspaper has published three articles in their monthly supplement “How to Spend It” about wood in its many forms. First one in August 1 2009 talks how the modern jewellery and accessories market is tapping into the organic qualities of wood and holding the ancient material as precious and versatile. Some designers highlighted here include famous names such as Browns, Ericson Beamon, Louis Vuitton and Harrods. In October 17 2009 a three page article about Finnish wood design graces its pages with large images and very complementary reviews on Finnish design values. It concludes in the thoughts “Increasignly, Finnish designers are daring to explore these wider reaches of their imaginations. Such idiosyncrasy has combined with real zeal for innovation and a sensibility attuned to ecological concerns to bring the work of Finnish designers back to international attention.” By Emma Chrichton-Miller Most recent article on this subject was buplished in May 1 2010, where they talk about rattan, bamboo and wicker as utterly contemporary choices for interior design. Since these there have been many more other articles in other publications too, but as Helsinki will be the 2012 World Design Capital, the focus from wood use has shifted to highlighting the design history of Finland. So with all of the potential market ready and available, wood fabric is not yet featured in fashion. This is not, however, because it has been rejected by the fashion world, but because it is not a choice yet. I have personally spoken to individual designers through my work who were entertaining the idea of using wood in their collection, in one way or another. One designer even wanted to carve the entire collection out of wood. So in short not only is the natural direction of fashion and consumer behaviourism in favour for a new and innovative fabric such as one made from wood, but also the interest for it has already begun. To date there are a few examples of wood in fashion. Most famously Hussein Chalayan created a very celebrated creation that begun as a table and then could be transformed into a skirt. The now late Alexander McQueen, created a false leg out of carved wood for athlete Aimee Mullins. Wood has featured more prominently in accessories in varying kind from shoes to bags. (Pictures below) Hussein Chalayan Autum Winter 2000-2001 Alexander McQueen 2009 In addition to these there are also others who have created articles of clothing using wood. A few select companies such as Tencel and Lenpur have even made fabric, but none have achieved what this project is out to achieve: a fabric made out of wood that is suitable for fashion clothing. In conclusion not only do the examples of fashion trends, press and current markets show a steady increase in eco materials, but the word on the streets about a fashion collection made entirely out of wood is already out. Requirements Funding Possible avenues for funding: -TEKES (the Finnish Funding Agency for Technology and Innovation) -Government grants -Corporate sponsorship Funds will be used to pay University research and development work (detailed below), experts’ input and consultation, press, fabric mills involvement and possible patenting costs. Research and development includes turning the fibres into fabrics by using already existing factory equipment and facilities in Finland. The estimated fund needed is 500,000€ Technology Currently available technology used for the processing of bamboo and other bast fibres will provide a starting point in The Flexible Wood Technology Project. These different fibres are listed on pages 3 and 4 with additional information in the appendices. Potential market for wood fabric According to the non-profit organization Organic Exchange, global retail sales of organic cotton apparel and home textile products reached an estimated $3.2 billion in 2008, a 63 percent increase from the $1.9 billion market in 2007. The top ten users of organic cotton include some of the biggest names in retail including Walmart, Nike, H&M, and the Inditex brand Zara. “The buzz around organic cotton will continue to increase. But as soon as it is public knowledge that organic cotton is going to remain a very small percentage of the overall raw material for the textile sector, we expect to see the emphasis shift toward other sustainable materials. We also expect to see a greater emphasis on reducing toxics and chemicals.” CKinetics report on Report on the Coming Decade, 2010 The message and direction of the use of organic cotton as an example is clear. As the market for varied sustainable textiles grows, many more firms will begin demanding sustainability from their manufacturers the same way they demand fair prices, fast delivery and high quality. On the next page is an example of how hemp and flax as an example is sold across the world Based on the market segmenting for flax and hemp the main market for the type of wood fabric we are developing lies in two main areas: clothing and furnishing (with linen being a distant tie with furnishing). Potential marketing strategies include: -Liasing with fabric agents across the globe -Selling directly to large companies in fashion, furnishing for interiors and luxury automotives -Subcontracting the sales to an already existing fabric mill supplier Research and development breakdown In the research we will explore whether wood is suitable for modern processes such as mechanized defibreing, classification, refinement processing, softening, cottonization, spooling and finally fabric manufacture. Wood properties that need research funding are: -Thermal properties -Mechanical properties -Shrinkage properties -Filler properties -Viscosity -Cottonization possibilities Viscosity explained Viscosity is a measure of the resistance of a fluid which is being deformed by either shear stress or tensile stress. It describes a fluid's internal resistance to flow and may be thought of as a measure of fluid friction. Cottonization of wood explained Cottonization mean using already existing fibre refinement methods to manipulate wood fibres suitable for blending with other natural fibres such as cotton, bamboo, silk, wool and linen. This process would allow endless possibilities for wood as a new sustainable fibre for the future. An example as to how wood fibre could be processed into being cottonizeable is by reducing its lignin levels in the same manor as in China’s Hemp Research Centre in Beijing, where through extensive development work the lignin content of hemp has been reduced from 8-10% to 0.2%. Conclusion There exists a rare and unprecedented opportunity to forge ahead with a new project with dual aims of promoting an new ethical and sustainable fabric production process and promoting the Finnish timber industry during Helsinki Design Capital year 2012. The market exists as has been described in the body of this feasibility study. The growing popularity of Bamboo fibre use by global fashion brands in particular has highlighted how an ‘innovative’ and sustainable fabric can be adopted into the mainstream. By working together with key Finnish institutions, harnessing new ideas, research and hard work the opportunity exists to truly innovate. With this in mind the proposed project partners are eager to move forward with the backing of TEKES. Appendices Tencel water absorption in extreme air humidity Lenpur Technical information: “The first phase of research was aimed at confirming the structural data available from IR studies, performed previously, using spectroscopic and chemical techniques. Confocal microscopic analysis was performed; however, it did not yield useful information regarding the structural differences in LENPUR and other cellulose fibres. Carbon-hydrogen analysis was performed with the objective of obtaining an in-depth chemical characterization. This testing established that fibre is composed of carbon, hydrogen, and oxygen thus ruling out the presence of other elements such as nitrogen and halogens. This result was confirmed by further SEM analysis. Based on these results, it was hypothesized that the deodorising action could be related to presence of natural substances, for example of terpenic nature, with double bonds able to easily react with components of perspiration (ex. α-pinene); or the structure of the fibre is characterized by elements that are present in larger quantities than in wood, like lignin, that are able to firmly bond these components by hydrogen bonding or other very firm bonds. It was presumed that the harsh chemical treatment that LENPUR fibre undergoes during spinning would extract any natural substances, such as the non-structural components of wood, so these substances would not remain in the yarn. In any case, it was determined that it would be useful to verify this by performing release testing on the fibre with possible reactive substances. Comparative extraction was performed on Modal, Viscose and Lenpur fibres with a low polarity solvent (CH2CL2) and with a polar solvent (CH3OH, C2H5OH). The extracts were analysed by NMR and did not highlight the presence of particular substances in any of the fibres. This result confirms that volatile components present in the pinewood used for producing LENPUR fibre are removed during the fibre preparation process and successive spinning operations. Evidently the difference between Lenpur and other fibres must be of a structural nature dependant on the wood raw material. Research was therefore turned to the examination of the adsorbent ability of substrates, examined using structurally defined molecules with different chemical and chemical-physical characteristics. Two active ingredients, Ketoconazole and Acetaminophen (or Paracetamol) were selected for testing purposes. The former has a complex structure, higher molecular weight, quite high lipofilicity, although it contains highly electronegative atoms with doublet electrons available for the formation of hydrogen bridges or electrostatic interaction with hydroxyfunctional groups present in cellulose or in lignin. Acetaminophen is a smaller, aromatic, molecule with a significantly lower molecular weight, characterized by a phenolic acid group and, on the whole, more polar than Ketoconazole. Considering that the adsorbent properties demonstrated by LENPUR are seen in finished fabrics used for making clothing, the adsorbent tests were performed on white fabric made using the previously analyzed fibres. Method used Known weights of fabric were soaked in a 0.2% Ketoconazole in ethanol solution for 1 hour. After that time, they were removed from the solution and the excess solution was allowed to drip off and the fabric was air dried. The samples were then extracted using methanol. The active ingredients in the extract solution and in the remaining saturating solution after the experiment were determined by HPLC. A second extraction was performed using the same method in order to have another measured parameter of absorbance power of the fibres. The results are shown in Table I. Table I FABRIC EXTRACT I mg/100 ml Cotton Viscose Lenpur 19.79 46.49 37.13 SOLUTION AFTER EXTRACTION I mg/100 ml 66.08 67.78 71.98 EXTRACT II mg/100 ml 9.79 12.54 7.87 Lenpur shows a trend of ability to bond with Ketoconazole that is similar to Viscose having a high absorbency value demonstrated by the total amount released in the two extractions. Testing with Acetaminophen was then performed under the same experimental conditions. The data is shown in Table II. Table II FABRIC EXTRACT I mg/100 ml Cotton Viscose LENPUR 4.05 10.35 0.29 SOLUTION AFTER EXTRACTION I mg/100 ml 77.15 71.78 58.98 All of the previously tested fibres showed a greater ability of bonding with Acetaminophen which is characterized by a lower molecular weight and by a greater polarity that permits it to better penetrate into their structure and remaining more strongly bonded. The greatest absorbency ability is shown by LENPUR demonstrated by the very low extraction concentration accompanied by a low concentration in the remaining solution. Evidently, LENPUR is able to establish stronger bonds with substrate demonstrating how different it is compared to the other fibres. “ By Professor .Fedele Manna