Rapid Manufacturing

advertisement

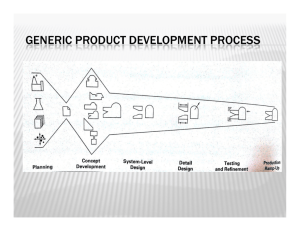

Rapid Manufacturing The product development landscape has evolved tremendously over the last 20 years. Product designs have become much more complex in both their shape and functionality, while the need of reducing time-to-market has increased. The evolution of CAD and computer technologies have brought forth a new way to produce prototypes know as Rapid Prototyping (RP). Rapid Tooling (RT) while developing from the same requirements as RP is generally is concerned with the production of tooling inserts. Both RP and RT help compress time-to-market of products and are therefore competitiveness enhancing technologies. Rapid Manufacturing (RM) is a term that embraces both RP and RT. Where it once took many weeks and lots of money to produce a prototype or tool from a design, with RM it is now commonplace to produce the same component in a matter of hours for a fraction of the cost. This evolution of RM has afforded companies the ability to verify and change designs more often while spending less time and money doing so. In general, RM is only cost effective for low volume component production. Such components meet high tolerance, temperature and strength requirements. Today, RM parts can be used as: Functioning components Moulds for plastic injection moulding Patterns for other tooling and manufacturing process Focus group models for sales analysis Marketing models to create literature and ad campaigns There are number RP technologies on the market, most of which work under the same fundamental principals. CAD data for the designed part, in a specific file format (usually STL nowadays), is processed and oriented in an optimal build position. The data is then sent to the RM machine where it is numerically sliced into thin layers. The RP machine then fabricates each two-dimensional cross section and bonds it to the previous layer. A complete prototype is thereby built by stacking layer upon layer until the prototype is completed. The automotive and aerospace industries are using RP to check the fit of specific parts as well as product design. Architects can use it in designing scaled models of proposed buildings and other structures. In the medical industry, Baxter Healthcare Corporation is using rapid prototyping to aid in the design of their medical products. Also, it is used in the design of telecommunications, computer, and consumer products. Rapid prototyped parts can also be tested for air and fluid flow. There are two main types of RM, subtractive and additive. Subtractive techniques involve the removal of material from a block to produce the prototype. The CAD data is converted into CNC data in order to control the CNC equipment for automated cutting of the block. Generally softer materials are machined to produce the prototype so that high cutting speeds can be used (for example polystyrene or plastic). Similarly, a prototype aluminium injection mould tool may be produced for evaluation, with this technique, whereas conventional prototyping methods would produce a steel die. Most modern RP techniques are however additive. The main RP techniques are discussed below. Rapid Prototyping Techniques Stereolithography (SLA) Patented in 1986, stereolithography started the rapid prototyping revolution. The first commercial system was introduced in 1988 by 3D Systems of Valencia, CA. The technique builds three-dimensional models from liquid photo-curable polymers that solidify when exposed to ultraviolet light. As shown in the figure below, a platform is lowered into the resin (via an elevator system), such that the surface of the platform is a layer-thickness (~ 0.1 mm) below the surface of the resin. A low-power highly focused UV laser then traces the boundaries and fills in a two-dimensional cross section of the model, solidifying the resin wherever it touches. Once a layer is complete, the platform descends a layer thickness, resin flows over the first layer, and the next layer is built. This process continues until the model is complete. Once the model is complete, the platform rises out of the vat and the excess resin is drained. The model is then removed from the platform, washed of excess resin, and then placed in a UV oven for a final curing. The model is then finished by smoothing the "stair-steps". Materials The materials used by SLA equipment are photo-curable epoxy-based resins that offer strong, durable, and accurate models. It is ideal for form, fit, and function testing as well as for visual aids and patterns for tooling. In many cases, SLA is capable of reproducing snap fits. In general SLA materials have a low heat tolerance with typical heat deflection temperatures around 46 ºC. Figure 1 Stereolithography machine. Selective Laser Sintering (SLS) DTM Corporation introduced selective laser sintering to the commercial world in 1992. SLS uses a laser to sinter powder based materials together, layer-by-layer, to form a solid model. The system consists of a laser, part chamber, and control system. The part chamber consists of a build platform, powder cartridge, and levelling roller. A thin layer of build material is spread across the platform where the laser traces a two-dimensional cross section of the part sintering the material together. The platform then descends a layer thickness and the levelling roller pushes material from the powder cartridge across the build platform, where the next cross section is sintered to the previous. This continues until the part is completed. Once the model is complete, it is removed from the part chamber and finished by removing any loose material and smoothing the visible surfaces Materials Duraform is a hard plastic and an example of a material used with this process. It processes high temperature resistance with a heat deflection temperature of around 140ºC @ 455kPa and has a tensile strength of about 44 MPa. Figure 2 Selective laser sintering machine. Fused Deposition Modeling (FDM) Stratasys Inc. introduced fused deposition modeling in 1990. FDM is a solid-based rapid prototyping method that extrudes materials, layer-by-layer, to build a model. The system consists of a build platform, extrusion nozzle, and control system. The build material is melted and then extruded through a specially designed head onto a platform to create a two-dimensional cross section of the model. The cross section quickly solidifies, and the platform descends where the next layer is extruded upon the previous. This continues until the model is complete, where it is then removed from the build chamber and cleaned for shipping. FDM is a good choice for conceptual models, as its dimensional tolerance is adequate (~ ±0.25 mm typical). Parts with finely detailed features are not recommended with this process as layer thickness used is generally around 0.25 mm. Layer thickness has an effect on the model dimensional exactness. Materials ABS is a hard plastic and an example of a material that is used with this process. It is ideal for form, fit and function testing as well as for other visual aids. In its finished form it is offered in several colours. The melting temperature of ABS is around 177ºC. Figure 3 Fused deposition modeling machine. Laminated Object Manufacturing (LOM) In this process, the laser cuts the slices from a sheet of paper which is then attached to previously cut layers. Unlike other processes, only the outline of the shape need be cut, but areas which are to be internal free space in the final model are finely crosshatched by the laser, producing a collection of small cubes in the final model. These provide support for material which may come on top, and can normally be removed at the end of the process. Occasionally, the unwanted cubes could become entirely enclosed within the model, and thus the process has to be interrupted so that the extraneous material can be removed before enclosure occurs. After the first layer is cut, the platform lowers out of the way and fresh material is advanced. The platform rises to slightly below the previous height, the roller bonds the second layer to the first, and the laser cuts the second layer. This process is repeated as needed to build the part, which will have a wood-like texture. Because the models are made of paper, they must be sealed and finished with paint or varnish to prevent moisture damage. In recent years Helisys, CA (the original developer) has developed several new sheet materials, including plastic, water-repellent paper, and ceramic and metal powder tapes. The powder tapes produce a "green" part that must be sintered for maximum strength. Figure 4 Laminated object manufacturing machine. Solid Ground Curing (SGC) SGC was developed by Cubital Ltd., which is jointly owned by Harwix GmbH, Clal Electronics Industries, Scitex Corporation, and private investors. Cubital is headquartered in Israel with subsidiaries in the United States and Germany. SGC (also known a the solider process) is illustrated in Figure 5. The production machine uses the CAD data to cure an entire layer of photopolymer in a solid environment. An ultraviolet light completely cures the material through a photomask. No post-curing is required. The machine currently marketed by Cubital can build parts to a maximum size of about 500 x 350 x 500 mm, which is around average for relatively large RP producing machines, and has building speed of about 55 layers per hour. This machine costs $470,000 [Cubital, 2000]. In this process, firstly photosensitive resin is sprayed on the build platform. Next, the machine develops a photomask (like a stencil) of the layer to be built. This photomask is printed on a glass plate above the build platform using an electrostatic process similar to that found in photocopiers. The mask is then exposed to UV light, which only passes through the transparent portions of the mask to selectively harden the shape of the current layer. After the layer is cured, the machine vacuums up the excess liquid resin and sprays wax in its place to support the model during the build. The top surface is milled flat, and then the process repeats to build the next layer. The entire building process concludes with the part embedded in a block of wax. The water-soluble wax is melted in a microwave oven, and the part is cleaned in warm water. Figure 5 Solid ground curing machine. Ink-Jet Printing Unlike the above techniques, Ink-Jet Printing refers to an entire class of machines that employ ink-jet technology. The first was 3D Printing (3DP), developed at MIT and licensed to Soligen Corporation, Extrude Hone, and others. As shown in Figure 6a, parts are built upon a platform situated in a bin full of powder material. An ink-jet printing head selectively "prints" binder to fuse the powder together in the desired areas. Unbound powder remains to support the part. The platform is lowered, more powder added and levelled, and the process repeated. When finished, the green part is sintered and then removed from the unbound powder. Soligen uses 3DP to produce ceramic moulds and cores for investment casting, while Extrude Hone hopes to make powder metal tools and products. Sanders Prototype of Wilton, NH uses a different ink-jet technique in its Model Maker line of concept modellers. The machines use two ink-jets (see Figure 6b). One dispenses low-melt thermoplastic to make the model, while the other prints wax to form supports. After each layer, a cutting tool mills the top surface to uniform height. This yields extremely good accuracy, allowing the machines to be used in the jewellery industry. 3D Systems has also developed an ink-jet based system. The Multi-Jet Modeling technique (Figure 6c) uses an array of 96 separate print heads to rapidly produce thermoplastic models. If the part is narrow enough, the print head can deposit an entire layer in one pass. Otherwise, the head makes several passes. Figure 6 Ink-jet printing machines. Rapid Tooling Techniques Tooling is one of the slowest and most expensive steps in the manufacturing process, because of the extremely high quality required. Tools often have complex geometries, yet must be dimensionally accurate to within a hundredth of a millimetre. In addition, tools must be hard, wear-resistant, and have very low surface roughness (about 0.5 micrometers root mean square). To meet these requirements, moulds and dies are traditionally made by CNC-machining, electro-discharge machining, or by hand. All are expensive and time consuming, so manufacturers would like to incorporate rapid prototyping techniques to speed up the process. Instead of several weeks to make a prototype mould, RT allows for the prototype to be made within a few days or hours. RT technology is also much less expensive than conventional mould prototype production, which can run into the €100,000’s. There are two RT methodologies, indirect and direct. Indirect methods use a RP model, as produced for example by one of the above RP techniques. Indirect RT methods The most widely employed RT techniques use RP masters to make silicone room temperature-vulcanising (RTV) moulds for producing plastic parts, and as sacrificial parts for investment casting of metal parts. These processes which are suitable for batches of 1-20 are known as ‘soft tooling’ techniques. RTV moulds RTV tools (also known as silicone rubber moulds) are an easy, relatively inexpensive, and fast way to fabricate pre-production tools. The main steps in this process are: 1. Start with a vented and gated RP pattern. 2. Place the pattern, supported by plasticine, flat against the bottom surface of a mould box. 3. Pour silicon rubber to form the first half of the mould. 4. Invert the first half of the mould, remove the plasticine, and attach the top mould box. 5. Pour silicon rubber to produce the second half of the mould. RTV tools can be used for moulding parts in wax, polyurethane, and a few epoxy materials. This process is best suited to parts where form, fit, or functional testing can be done with a material that mimics the characteristics of the production material. Investment casting The use of RP sacrificial models for investment casting was one of the first applications of RP. The RP model for this purpose can be made by most of the RP techniques. Investment casting is considered to be the quickest and most robust method available to accurately produce complex metal prototype parts with good surface finish. The integrity of investment cast parts means that cast parts are ideal for the most demanding applications. The technique of using a disposable pattern (the investment) as the basis for casting a metal object dates back to the 15th century. In the modern era, World War II provided an urgent need for accurate, complex metal parts with good surface finish that traditional machining could not address. The initial discovery that a lost art provided a practical metalworking technique caused great enthusiasm. Investment casting was found practical for many wartime needs, and during the postwar and modern periods it expanded into many applications where complex metal parts were needed. Growth of the investment casting industry has continued. The process has an excellent reputation for reliability, value, accuracy, versatility, integrity and good surface finish. The marriage of investment casting and rapid prototyping techniques as a means to rapidly produce the investment pattern has resulted in even greater economies and timesavings in the manufacture of small quantities of complex metal parts. The investment casting process follows these steps: A gating system is added to the pattern(s) to form a ‘tree’. The tree is dipped into a ceramic or plaster slurry. The ceramic (plaster) coating is allowed to dry and forms a shell. Step 2 and 3 are repeated several times to build up a thicker shell coating that is strong enough to hold the molten metal during the casting process. 5. The pattern is melted or burned out of the shell. 6. Metal is poured into the shell to form the parts. 1. 2. 3. 4. Specific example: Thermojet Wax Pattern fabricator is a RP machine that produces foundry-friendly wax patterns directly from the 3D model. The Thermojet Wax material is very similar to production investment casting wax material, and has proven over time to be a consistent high-quality performer for the casting of both ferrous and non-ferrous metals. The wax has a melting point of 85-95 C, and can be deposited to achieve an accuracy of 0.5% and a layer resolution of 0.04 mm. - Tolerances of ± 0.05 mm/cm on most parts and features - Aluminum (A356), stainless steel (304), and zinc (ZA8) (other alloys are available) - Part Sizes up to 500 x 500 x 500 mm - Typical IC surface finish is 125 RMS Direct RT methods Direct RT methods can be divided into two main groups, ‘firm’ tool producing methods and ‘hard’ tool producing methods. The first group produces tooling that is less expensive and with shorter lead times. These tools are capable of short prototype runs of approximately 50-100 parts using the same material and manufacturing route as for the final products. The second group includes RT methods that allow for pre-production and production tools to be built. This latter group is based on the fabrication of sintered metal (steel, iron and copper) powder inserts infiltrated with copper or bronze. These tools can be used to produce similar numbers of parts as conventionally produced moulds (250100,000 parts). Commercially available examples of RT processes that produce these moulds include KeltoolTM from 3D Systems, DTM RapidToolTM process, EOSINT Metal from EOS, and Three-Dimensional Printing of parts from Soligen. Aerospace Industry Example The Boeing Commercial Airplane Company has used rapid prototyping technology to produce parts for design support, proof of concept, and as a visual aid. Their rapid prototyping machines have been used to confirm the design of door seal support structures and to build parts and silicon rubber moulds for wind tunnel projects. Pratt & Whitney has been actively involved with rapid prototyping technology since 1988. This company finds a significant benefit in that this new technology aids in the identification of design errors prior to manufacturing involvement. Also, rapid prototyping facilitated concurrent engineering practices by improving communications among design engineers and between engineering and manufacturing departments. A physical part is more consistently interpreted than a sketch. Rapid prototyping aids in manufacturing producibility studies. The plastic replica of the part can help the manufacturing shop prove out tooling and fixturing while the actual parts are being produced. Automotive Industry Example Chrysler Corporation has been actively involved with rapid prototyping technology since 1990. Here are some instances of how this new technology has helped Chrysler. In the area of design verification, two engineers on an engine upgrade program were given the task of designing the mating of a distributor cap and body. The parts were built on an SLA, and when they were put together, they did not fit. The distributor cap engineer made a design change and built another part in 24 hours. The new part fit. If conventional methods had been used, the problem would not have been seen until the prototypes came back weeks later. In the area of air flow testing, Chrysler used SLA to find the optimum size for an ambient air duct. Three models were made in one day as opposed to four weeks using conventional prototyping. The models were tested, and the best choice was selected. Chrysler has also used rapid prototyping to quickly create precise master patterns for secondary tooling applications such as room-temperature vulcanising (RTV) moulding, sand casting, resin transfer moulding, vacuum forming, and squeeze moulding. Parts produced include centre consoles, interior trim panels, and instrument panel components. Other Examples In addition to being fast, RP models can do a few things metal prototypes cannot. For example, Porsche used a transparent stereolithography model of the 911 GTI transmission housing to visually study oil flow. Snecma, a French turbomachinery producer, performed photoelastic stress analysis on a SLA model of a fan wheel to determine stresses in the blades. Specific Surface (Franklin, MA) uses RP to manufacture complicated ceramic filters (which cannot be made by conventional means) that have eight times the interior surface area of older types. The filters remove particles from the gas emissions of coal-fired power plants.