Final Design Proposal - Villanova University

advertisement

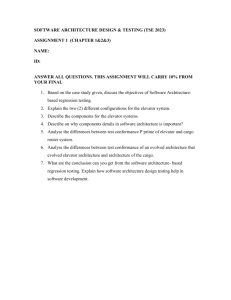

A Proposal For VERTICAL TO HORIZONTAL TRANSITION SYSTEM FOR UNITED STATES NAVY CARGO/ORDNANCE ELEVATOR By Daniel Ballister Ben Campanella Jr. – Team Leader Brian Griffin Timothy Troy Submitted to Department of Mechanical Engineering Villanova University 25 November 2003 Table of Contents 1 2 INTRODUCTION ...................................................................................................... 3 BACKGROUND INFORMATION AND STATE-OF-THE-ART ........................... 4 2.1 BACKGROUND INFORMATION ................................................................... 4 2.2 DESIGN REQUIREMENTS .............................................................................. 7 3 PROBLEM STATEMENT AND DESIGN OBJECTIVES ..................................... 10 3.1 QUALITY FUNCTION DEPLOYMENT (QFD) ............................................ 10 3.2 PRODUCT DESIGN SPECIFICATION (PDS) ............................................... 11 4 PRELIMINARY DESIGNS ..................................................................................... 13 5 STATEMENT OF WORK AND DESIGN SCHEDULE ........................................ 18 6 REFERENCES ......................................................................................................... 25 APPENDIX I – EXISTING PATENTS ........................................................................... 26 Table of Figures Figure 1 - Current United States Navy Cargo/Weapons Elevators [2] .................... 4 Figure 2 - Basic Design of Linear Induction Motor (LIM) [3]...................................... 5 Figure 3 - ENNA Linear-Motor-Driven Vertical Transportation System [7] ............. 7 Figure 4 - Land Based Engineering Sight Elevator System at Naval Surface ....... 8 Figure 5 - Quality Function Deployment Diagram (QFD) [1] ................................. 10 Figure 6 - Preliminary Design Concept #1 ................................................................. 13 Figure 7 - Preliminary Design Concept #2A .............................................................. 14 Figure 8 - Preliminary Design Concept #2B .............................................................. 15 Figure 9 - Preliminary Design Concept #3 ................................................................. 16 Figure 10 - Preliminary Design Concept #4 ............................................................... 17 Figure 11 – Gantt Chart ................................................................................................ 22 Figure 12 – PERT/CPM Chart...................................................................................... 23 Index of Tables Table 1 – Decision Matrix ............................................................................................. 20 Table 2 – Total Manpower Estimate ........................................................................... 21 1 INTRODUCTION The current system for conveying weapons and supplies aboard United States naval vessels consists of a cable operated elevator configuration. The U.S. Navy has taken the initial steps to radically redesign this system through the use of linear induction motors thereby eliminating the need for cables. The application of linear induction motors will theoretically allow the elevator to operate on three axes rather than just one. This proposal will outline the efforts of this design group to create a transition system that will transfer an elevator from vertical to horizontal motion. The ability of a weapons and supply elevator to move vertically and horizontally through the ship will dramatically improve the capability of the ship to prepare for war as well as decrease the time needed to replenish its supplies while at sea.[1] The need for an elevator that operates in more than one axis has become clearly apparent to those in charge of United States naval operations. Currently, ships that must be replenished at sea require several days to process and stow supplies (known as “strike down”) that have been dropped off by aircraft or transferred via a pulley system. The primary reason for the sluggishness of this process is the current elevator system. Supplies must be placed on the elevators, taken to the appropriate deck, and then manually transported across the deck to their proper stowage places. This process is not only slow, but also inefficient and arduous for all involved.[1] The design of a vertical to horizontal elevator transition system will greatly improve the standard U.S. naval ordnance/cargo elevator. Preliminary design concepts have been discussed among the four group members. A choice has been made to go forth with a design effort to implement the most viable of the preliminary design concepts. Later in this report the design requirements outlined by the United States Navy, a Quality Function Deployment (QFD), and a Product Design Specification (PDS) are included to further specify the aim of this design effort. In addition, the needs and wants of the navy will be addressed. The design group will show how these needs and wants are satisfied by the chosen design concept. Lastly, this proposal will set forth a list of tasks and objectives needed to complete the design effort. This list is used to create an appropriate timeline to finish each portion of the design effort. In addition, it is used to estimate the manhours needed to properly design, prototype and report this design effort. Having now chosen a design and set forth a plan for making that design a reality, the major tasks of designing and analyzing the system must be undertaken. Barring unforeseen setbacks, it is the belief of the design group that the project will be completed on time, and within budget. 2 BACKGROUND INFORMATION AND STATE-OF-THE-ART 2.1 BACKGROUND INFORMATION In order to implement the type of elevator system the navy is requesting, the team will require the use of a different type of propulsion system. Current supply elevators aboard navy ships use a standard cable and wound drum configuration.[2] Figure 1 shows the cargo/weapons elevators that exist on current United States Navy vessels. The elevator on the left of Figure 1 has a load capacity of 16,000 lbs, while the elevator on the right has a load capacity of 12,000 lbs.[2] Figure 1 - Current United States Navy Cargo/Weapons Elevators [2] The elevator cars ride on rails at each of the four corners, and are raised and lowered from above by steel cables. This elevator design is unable to move in more than one axis due to the hindrance of the cables. For this reason, the navy is currently researching the use of linear induction motors (LIMs) for use with a new elevator design.[1] The incorporation of LIMs would dramatically increase the capabilities of elevators. Several cars could ride in the same elevator shafts, and current height restrictions for cable driven elevators would be nullified.[3] The basic linear induction motor design is shown in Figure 2. A LIM is a rotary motor reconfigured by laying out its primary and secondary parts in a linear fashion. Here, the secondary part is on the vehicle and the primary on the track. The opposite configuration is also possible but unrealistic, as electricity would have to be supplied to a moving car. [3] Figure 2 - Basic Design of Linear Induction Motor (LIM) [3] The linear induction motor has many modern applications. They are implemented on roller coasters, monorails, and baggage carriers to name a few. They are also capable of launching aircraft from naval carriers through the use of a catapult system. A major manufacturer and distributor of LIMs is Force Engineering. [4] The basic operation of rotary induction motors (RIMs) is relatively simple. An RIM has only 2 main parts, the rotor and the stator [5]. Around the stator are wound two or three wires in a specific pattern – two or three wires depends on whether the RIM is a two current or three current motor. As the appropriate current is supplied to the windings, a rotating magnetic field is produced in the air gap between the two main parts. This magnetic field induces currents within the rotor which, at any instant, oppose the direction of the magnetic field. This causes the rotor, as it spins, to be alternately attracted and repelled from the stator. Thus, an induction motor is basically a constant speed motor. The speed can be changed only by changing fixed parameters within the motor design.[6] This system can be linearized by laying the rotor and stator flat against each other. In this configuration, the rotor will move along a extended track of stators, or vice versa. Therefore, in order to accelerate a roller coaster car, many motors must be used along the track, each one inducting at a slightly higher speed. This configuration creates a magnetic "wave" along the track, and the cars are pushed ahead of the wave with permanent magnets affixed to the bottom of the cars.[5] There are many advantages to linear induction motors over conventional motors. LIM’s have no moving parts to get clogged or dirty, and therefore maintenance is very minimal. On regular motors complications can be found in gears, chains, and belts, while on LIM’s, these mechanisms are nonexistent. [4] Induction motors can work at variable speeds and are able to accelerate and decelerate rapidly despite the working conditions – underwater, hot or cold surrounding temperatures, or even nuclear conditions. Linear induction motors can serve in many ways, and Force Engineering has distributed LIM’s for both means of transportation and pleasure. In 1991, they sold 130 LIM’s to Euro Disney for use in the theme park rides, while in 1993, 500 LIM’s were purchased for use in the Senate People Mover in Washington, DC. [4] The most significant success in the expanding use of the linear induction motor was its first implementations into catapult systems in two roller coasters in the United States. These catapults accelerate seven to nine ton cars to 70 miles per hour in under four seconds. [4] Beginning in 1989 and ending in 1995, the Underground Development Utilization Research Center of the Engineering Advancement Association of Japan (ENNA) began work on a linear-motor-driven vertical transportation system. The test system was designed to run without the use of cables on a vertical-to-horizontal curved or branched path. A schematic of the test system is shown in Figure 3. [7] Figure 3 - ENNA Linear-Motor-Driven Vertical Transportation System [7] This test system was built to investigate and validate the use of LIMs in elevator design. LIMs were used as the main propulsion while a cantilever beam hung away from the track, connected to a carriage. The carriage was connected to the cantilever in such a way that it rotated as the main cab rode along the track and transitioned from vertical to horizontal travel. In this way, the designers of the system were able to keep the carriage upright while it traveled the length of the track. The design proved to be successful, but did not receive further funding for implementation in mining as it was originally intended. [7] A search was conducted on the United States Patent Office website regarding elevators. The purpose of this research was to identify any existing designs that would either aid or hinder this design effort. This search resulted in the determination that there are no existing elevators which are capable of performing the tasks required by this design effort. Patents which had some correlation with this project were recorded and are provided in Appendix I along with a short description. 2.2 DESIGN REQUIREMENTS The Naval Surface Warfare Center (NSWC) has set forth some design requirements that need to be incorporated into the finalized system. They have also mentioned some features that they would like to see incorporated, but these are not critical to the functioning of the system. Finally, some portions of the project have remained undefined and have been left to the design group to create. Figure 4 shows the current elevator system in operation at the Land Based Engineering Sight at the Naval Surface Warfare Center in Philadelphia, PA. This elevator will be the basis for future research and development. [2] Figure 4 - Land Based Engineering Sight Elevator System at Naval Surface Warfare Center (Philadelphia, PA) [2] The vertical to horizontal transition system must have a vertical trunk that has four T-rails as in the current elevator system. The four rail system needs to be kept in place for several reasons. Since this is the existing system, the navy has the resources for building and maintaining the current trunks, and it would be economical in the long run to keep this structure. The four rails also provide stability for the platform while at sea. In the case of a failure of up to three linear induction motors, the brakes on the elevator platform will engage the four rails, preventing the platform from free falling. The rail followers themselves must also be in contact at all times. In the current aircraft carrier weapons elevators, rail gaps are encountered because of explosion-proof hatches in the trunk that open to let the platform travel through. The platform was designed with two sets of rail followers, also called guide shoes, for each rail. When one is disengaged at the gap, the second follower still remains in contact. The maximum rail gap distance has been predefined to be 20 inches. The design parameters present in the existing system may need to be altered due to the innovative nature of this project. The new elevator will be rated at 24,000lbs and the platform itself will weigh 10,000lbs. According to naval requirements, the dynamic load of the elevator is considered to be 150% of the rated load to account for sea state conditions. The combined stresses for each guide rail component shall not be greater than 35 percent of the yield point of the material at any point. Another criterion, while not finalized, requires that the reaction plates for the linear induction drive be placed at the four corners of the long ends of the platform. Most importantly, the entire rail switching process must be failsafe. If anything were to stop working during the vertical/horizontal switch, the platform would not freefall. [1] According to Navy Elevator Mil Spec MIL-E-17807, the elevator system must be designed to be failsafe in operation such that the ability to maintain the safety of the weapons, cargo, equipment, and personnel at all times. Failure of the power source or powered operated drive mechanism shall not result in damage to the weapon, cargo or handling equipment, jeopardize the safety of personnel, or result in uncontrolled movement of the equipment and load. In the event of a power failure, the elevator shall be immobilized. [1] The NSWC has also requested, but not required, that the switching process be kept to a minimum amount of time and power. It was suggested that the actuators used in the design be electrical rather than hydraulic or pneumatic, since future naval vessels will be operated entirely on electrical power generated at a central location. The design should also mimic the current elevator in terms of general geometry, trunk orientation, control system, maintenance, and safety. [1] It has been left up to the design group to decide on the orientation of the horizontal rails. Ideally, the navy would like a system that is able to switch an elevator from the vertical direction to the fore and aft direction as well as the cross ship direction, but for this design effort they only require that the elevator move from vertical to horizontal and vice versa. The cross ship direction switch can be done at a separate point in the trunk. The horizontal rail orientation remains undefined; the constraints are stability in the pitch, roll and heave environment found on ships.[1] By using what is known about past elevator design and taking what is now known about linear induction motors, it will be possible to blend the two technologies together to create a radically new concept. The ultimate goal of this design effort will be to successfully demonstrate a feasible transition system for a LIM powered elevator. This system will allow the elevator to travel in three axes, while fulfilling the design requirements set forth by the United States Navy. 3 3.1 PROBLEM STATEMENT AND DESIGN OBJECTIVES QUALITY FUNCTION DEPLOYMENT (QFD) 1 3 9 9 3 1 9 3 3 9 9 3 3 1 3 9 Cargo Orientation 9 9 9 9 3 9 9 9 M S S 9 W M M 3 3 S M 9 9 3 3 3 3 1 3 3 S S S S M 3 9 9 3 Lift capability Fabrication Cost Acutators 3 3 9 9 3 9 3 3 50 3 S M M S S M years 34,000 S W lbs 9 S W M 50,000 S $ 9 9 W W M W M 15 3 sec. Units Transition Procedure Time of transition Reaction Plate Orientation 9 9 Customer Importance 3 3 9 9 3 1 Life Span of Apparatus 3 Guide Shoe Orientation Factor of Safety Rail Material 3 3 9 3 9 movments 5 Target Values 1 1.5 9 = Strong 3 = Moderate 1 = Weak Functions Vertical to horizontal transition Constant contact Stability During power failure immobilize elevator Dimensional similarity with current system Strength 24,000lbs Rated load 150% of rated load Total stress <35% of yield point Ergonomics Ease of use Ease of maintanence Ease of upgrade Materials Non-corrosive in seawater environment Lightweight Additional Features Reaction plates at 4 corners Minimize switching time Minimize space used Electric actuators Cost Technical Difficulty Platform Material Figure 5 shows the Quality Function Deployment Diagram (QFD). The customer requirements are stated in the left column and are broken down into categories of function, strength, ergonomics, materials and additional features. All of the requirements are considered “needs” except for the additional features, which are not critical to the design but still desirable. The engineering characteristics are listed across the top, and the relationship matrix in the middle shows the correspondence between the two groups. Customer importance is ranked on the far right column according to the same scale as the relationship matrix. Technical difficulty is along the bottom of the diagram; this row indicates how complicated the design process for this particular characteristic will be. The target values and units are based on preliminary design requirements and may change as the design process progresses. Figure 5 - Quality Function Deployment Diagram (QFD) [1] 3.2 PRODUCT DESIGN SPECIFICATION (PDS) The PDS Statement was constructed using the information provided by the Naval Surface Warfare Center in conjunction with research conducted by the design group. This information was evaluated and simplified to form the PDS. [1] Product Title Vertical to Horizontal Transition System for U. S. Navy Ordnance/Cargo Elevator Purpose The purpose of this design effort is to design a system capable of allowing a naval ordnance/cargo elevator to transition from vertical to horizontal motion. New or Special Features The cables used in typical elevator designs are eliminated. The elevator car/platform is driven by linear induction motors. The elevator car/platform will be able to move in more than one axis. Competition There are several contractors currently investigating this concept for the U.S. Navy. Intended Market This design will be used primarily by naval warships, but can be extended to civilian applications in the future. Need for Product The new capabilities of this design will greatly diminish the time necessary to replenish the supplies of warships at sea. It will become more convenient to transport ordnance and goods through naval vessels. Relationship to Existing Products Line No products currently exist with the capabilities of the proposed design. Market Demand The primary customer would be the United States Navy, but the overall concept could be marketed for hundreds of applications in the private sector. Most common would be people movers within high-rise buildings. Price Price is not a main concern for the customer, as this is an experimental design. Price considerations will be accounted for at a later date in the event the design is mass- produced. Functional Performance The elevator must ride smoothly through transition in the railway system. The elevator system must allow all possible ordnance and cargo configurations to be carried without hindrance. Physical Requirements The new elevator system will be dimensionally equal to the current design to facilitate ease of implementation and lessen the need for major redesign of naval vessels. The new design will need to meet the lifting capabilities of the current design. The new design will be designed to withstand 150% of the expected operational loads. Service Environment The elevator system will be implemented in future naval vessels. The system will need to be able to function properly despite the normal wear placed upon it by naval service. The system must not be affected by the pitch and roll of the naval vessel. Life-cycle Issues Elevator must last the operational life of the vessel in which it is installed. Normal repairs are expected, but should not affect the life of the elevator system. Human Factors Operation of the elevator system should be accomplished without the need for special training by the operator. Elevator system should transition from vertical to horizontal motion autonomously. Corporate Constraints Elevator system must conform to Navy Elevator Mil Spec MIL-E-17807. Legal Requirements Elevator system must not impinge upon current elevator design patents. 4 PRELIMINARY DESIGNS The major challenges of this design effort originate from the ultimate goal of the project. The elevator must function while meeting all of the requirements set forth by the US Navy. First, the cargo/ordnance elevator must remain in contact with the four rails at all times. This makes transition from vertical to horizontal motion difficult and unorthodox. Second, vertical rails must be bypassed in order for the elevator to properly make the transition. Third, accommodations must be made to keep the proper clearances between the elevator and walls for the Linear Induction Motors. Fourth and most importantly, the elevator must make the transition safely while bearing the large loads that will be encountered through normal operation. The preliminary design idea shown in Figure 6 shows an overall diagram of the vertical to horizontal transition of the cargo/ordnance elevator. This design contains two major features. First, two support rails move into place under the elevator platform and engage the four corners of the platform. This action serves a dual purpose. It acts to support the elevator from below and permits the vertical rails at one end of the platform to disengage. This next major feature of the design, the disengagement of the vertical rails, clears the horizontal path of the cargo/ordnance elevator. The rails split in the middle and rotate ninety degrees until they reengage with the horizontal rails. With the path clear and the horizontal rails now fully engages, the elevator may pass from vertical to horizontal motion along the four horizontal rails. Figure 6 - Preliminary Design Concept #1 Figure 7 shows the basic layout of a stationary rail design. The stationary sail design consists of a four rail system where the four rails are located at the corners of the elevator platform. These rails are recessed into the surrounding walls so that the platform moves with a specified clearance between the platforms and the walls. Because of the spacing of the supporting rollers, the rollers do not need to move when the platform needs to transition to horizontal motion. At the rail intersections (Shown in Figure 8), the horizontal and vertical rails meet at a perpendicular angle and the horizontal rails fit into a space in the vertical rails as shown in the drawing. The elevator moves up or downwards until the rollers are lined up with the horizontal rail sections and then the elevator can simply move horizontally and the rollers will automatically engage the rails. Because the rails are recessed into the surrounding walls, the rails will not impede the elevator’s motion. If the elevator needs more stability while making the transition, additional rollers can be designed to move from the elevator and engage the horizontal rails. Figure 7 - Preliminary Design Concept #2A Figure 8 - Preliminary Design Concept #2B This design involves rotating horizontal, C-shaped rails about an axis between its to ends. The rails are also connected at its ends to a circular track which allows them to rotate about the vertical axis and switch to either the fore/aft or cross ship direction. This setup also uses the existing four T-rail (Parts D) system common to the cargo elevators currently in use. When the elevator platform approaches in the vertical direction the C-rails (Parts A in Figure 9) are in their disengaged position. The elevator will continue rising to a height marginally above the horizontal rails (Parts B). The C-rails will then move to the “engaged” position by rotating about the horizontal axis. The shape and size of the C-rails will allow them to move through a small gap in the vertical rails. This gap will be smaller than the 20 inches proscribed by the navy. When the C-rails are in the “engaged” position they will be in line with the horizontal rails, some system that has yet to be determined will move the vertical rails out of the way, and the car will lower onto the rails and be free to travel in the horizontal direction. Another strength of this design is that when the elevator platform is resting on the C-rails they will be able to rotate along the circular track (Part C). This gives the elevator a third direction of motion, which will be greatly advantageous when moving cargo through the ship. Figure 9 - Preliminary Design Concept #3 Figure 10 shows the basic layout of preliminary design concept #4. In this elevator design, there exist two systems of rails that the elevator platform will travel along. The first rails are in the vertical direction, and will allow the elevator to travel from level to level. In the drawing, the design is for the vertical rails to ride through the short sides of the elevator platform. This does not necessarily have to be the case. The rails can be located on the longer sides of the platform. In both cases, the rails are “T” rails that will allow the linear induction motors to travel along them. The second set of rails will be a horizontal pair, also “T” rails for the same reason, but can be either “T” up or “T” down. The ideal situation would be for the rails to be “T” down so as to reduce stress on the rails as the platform travels across them. These rails will allow the platform to slide horizontally through each individual deck. The engagement of the horizontal rails will occur as follows. The platform will travel along the vertical rails to a distance slightly above that of a given deck. The horizontal rails with then extend out underneath the platform and engage with the linear induction motors under the platform. After they engage, the vertical rails will then retract away from the elevator platform in either a linear fashion or a circular manner, and the cart will slide horizontally along the deck. (Note: the vertical linear induction motors on the platform are not drawn, as well as the followers on the vertical rails.) Figure 10 - Preliminary Design Concept #4 5 STATEMENT OF WORK AND DESIGN SCHEDULE The final design chosen from the preliminary designs set forth above is Preliminary Design Concept #3 (Figure 9). The decision matrix shown in Table 1 provides a full breakdown of the factors leading to this choice. The strength of this design lies in four main areas. First, the rotating rail feature allows for contact between the guide rails and the guide shoes at all times. Other preliminary designs either caused loss of contact between the rails and the rail followers, or contained complex rail motion unsuitable for keeping the platform stable. Secondly, the chosen design keeps the rails at the far corners of the long end of the platform, similar to the current layout. This position allows for easy loading and unloading of the elevator from any of its four sides, regardless of its location in the ship’s hull. Moving the rails to the corners of the short sides would obstruct the loading of the elevator at certain decks, and is therefore unacceptable. The third characteristic that set the rotating rail design apart from the others is its ability to rotate. This attribute will need simple, off-the-shelf electric motors to actuate the major motion of the system. The other proposed designs had rails moving in a telescoping or pivoting motions, requiring expensive linear actuators. The rejected designs would also create cantilevered rails to support the weight of the platform. These designs would have been difficult to design to meet all of the necessary safety requirements. The C-shape of the “flip-up” rails in the chosen design avoids high stress concentrations and distributes the weight of the elevator car evenly. Finally, the rotating rail design would allow for transition of the rail car in two horizontal directions, thus allowing the car to move from bow to stern as well as port to starboard. These four design attributes greatly distinguished the chosen design from the other preliminary design. The manpower estimate shown in Table 2 is based on predicted completion times. The values displayed in this figure are liable to change during the course of the project. In addition, team members are assigned to each of the major design tasks. The Gantt chart shown in Figure 11 was based on the manpower estimates referenced above. In order to complete all of the tasks before the deadline for this design effort, it is necessary to divide the work between the four team members. During the course of the project, multiple design tasks will be split up between the four group members. This allows the resources of the group to be maximized and facilitates the timely completion of the project. The Pert and CPM chart in Figure 12 reiterates the schedule laid out in the Gantt chart. It also displays the critical path of the project, which dictates the limiting tasks hindering the progression of the design effort. The cost estimate analysis is being developed in conjunction with the navy and fabricators. A detailed figure was requested by the navy so the proper amount of money may be allotted to this design effort before the end of the calendar year. Talks are currently continuing between the design group, the U.S. Navy, and possible prototype fabricators. It is the understanding of the design group at this time that the navy has sufficient funds to allocate to this project. Table 1 – Decision Matrix Criteria Vertical to horizontal transition Constant Contact Stability During Power Failure immobilize elevator Dimensional Similarity with Current system Switch to cross-ship direction Rail Gap < 20" 24,000 lbs rated load 150% strength of rated load Total stress at any point <35% of yield point Ease of use Ease of maintenance Ease of upgrade Non-corrosive material in seawater environment Lightweight Linear induction motor does not obstruct load/unload Rail orientation does not obstruct load/unload Minimize switching time Minimize space used Electric actuators Cost Overall Rating Weight 10 10 7 9 6 2 8 6 9 9 4 4 5 7 7 6 6 3 5 2 4 129 Weight Fraction 0.08 0.08 0.05 0.07 0.05 0.02 0.06 0.05 0.07 0.07 0.03 0.03 0.04 0.05 0.05 0.05 0.05 0.02 0.04 0.02 0.03 I - Folding Rails 90 6.98 10 0.78 30 1.63 60 4.19 40 1.86 0 0.00 100 6.20 100 4.65 100 6.98 90 6.28 90 2.79 70 2.17 50 1.94 60 3.26 90 4.88 90 4.19 10 0.47 70 1.63 90 3.49 80 1.24 80 2.48 68.06 II - Stationary Rails 80 6.20 10 0.78 30 1.63 60 4.19 10 0.47 0 0.00 100 6.20 100 4.65 100 6.98 80 5.58 80 2.48 80 2.48 50 1.94 60 3.26 100 5.43 90 4.19 10 0.47 80 1.86 90 3.49 100 1.55 70 2.17 65.97 Concepts III - Rotating Rails IV - Retracting Rails V - Two Part Elevator 90 6.98 80 6.20 100 7.75 100 7.75 70 5.43 100 7.75 50 2.71 30 1.63 100 5.43 70 4.88 70 4.88 30 2.09 90 4.19 90 4.19 40 1.86 100 1.55 0 0.00 0 0.00 100 6.20 100 6.20 100 6.20 100 4.65 100 4.65 100 4.65 100 6.98 100 6.98 100 6.98 60 4.19 60 4.19 60 4.19 40 1.24 30 0.93 10 0.31 40 1.24 30 0.93 40 1.24 60 2.33 50 1.94 40 1.55 60 3.26 60 3.26 60 3.26 60 3.26 70 3.80 30 1.63 100 4.65 90 4.19 10 0.47 100 4.65 90 4.19 10 0.47 60 1.40 60 1.40 50 1.16 60 2.33 60 2.33 90 3.49 100 1.55 70 1.09 100 1.55 40 1.24 40 1.24 60 1.86 77.21 69.61 63.88 Table 2 – Total Manpower Estimate Task Number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 Project Tasks Design Elevator Chassis/Car Design Vertical Rail Reposistioners Design Flip-up Rails and Rail Mounts Design New Horizontal Rails Design Horizontal Rail Followers Analyze Stresses on Chassis/Car Analyze Stresses on Vertical Rails Repositioners Analyze Integrity of existing Vertical Rail Followers Analyze Stresses on Flip-Up Rails and Mounts Analyze Stresses on New Horizontal Rails Analyze Stresses and Integrity on New Followers and follower positions Analyze Stresses on actuators/motors Prepare for Mid-Semester report Choose appropriate actuators/motors Create Final Design drawings and specifications Choose Contractor to manufacture prototype Build working prototype Test working prototype Make design corrections based on prototype testing Update design drawings to include design corrections Prepare for oral presentation Write final design report for customer Number of Days to Complete 14 21 17 10 8 11 14 6 7 7 7 10 3 7 40 7 40 7 7 7 7 36 Team Member(s) Hours Per Day Per Man-hours Assigned Person Ben, Brian 2 56 Dan, Tim 2 84 Dan, Tim 1 34 Ben, Brian 0.5 10 Ben, Brian 0.25 4 Ben, Brian 2 44 Dan, Tim 2 56 Dan, Tim 1 12 Dan, Tim 2 28 Ben, Brian 1 14 Dan, Tim 2 28 Ben, Brian 1 20 Group Effort 2 24 Ben, Brian 0.25 3.5 Group Effort 1 40 Group Effort 0.25 1.75 Contractor and Group 2 80 Group Effort 1 7 Group Effort 1 7 Group Effort 0.5 3.5 Group Effort 1 28 Group Effort 1 36 Total Man-Hours 620.75 hours Figure 11 – Gantt Chart Analyze Stresses on Chassis/Car ET LT 8 days 14 days Design Elevator Chassis/ Car ET Analyze Stresses on Actuators/Motors LT 10 days 20 days Design Flip-up Rails and Rail Mounts ET 14 days 21 days Choose Contractor to Manufacture Prototype ET LT 4 days 10 days ET LT 5 days 10 days Update Design Draw ings ET LT 5 days 10 days ET ET Prepare Mid-Sem ester Report ET LT 1 days 5 days Build Working Prototype ET LT 35 days 45 days Create Design Drawings and Design Specifications LT 4 days 8 days LT 17 days 27 days ET LT 35 days 45 days Test Working Prototype ET LT 5 days 10 days Make Design Corrections ET Write Final Design Report LT ET 5 days 10 days Prepare Oral Presentation ET ET ET LT 7 days 14 days LT 12 days 21 days Design Horizontal Rail Follow ers ET LT 6 days 10 days Analyze Stresses and Integrity on New Horizontal Follow ers and Follow er Positions ET LT 5 days 10 days Analyze Stresses on New Horizontal Rails ET LT 5 days 10 days LT 5 days 10 days Analyze Stresses on Vertical Rail Repositioners Design New Horizontal Rails LT 5 days 10 days Analyze Integrity of Existing Vertical Rail Follow ers Design Vertical Rail Repositioners ET LT 12 days Analyze Stresses on Flip-up Rails and Mounts LT Begin Design Effort ET 7 days Choose Appropriate Actuators/Motors Figure 12 – PERT/CPM Chart (Note: PERT/CPM chart constructed using trial version of SmartDraw Software) LT 20 days 30 days End of Design Effort CONCLUSION As previously stated, there are many challenges facing the design of this multidirectional elevator. The design must comply with all load requirements set forth by the navy and it must safely transition from vertical to horizontal motion. The four designs set forth try to incorporate all of the requirements of the elevator while using very different ideas of how the elevator will operate. They consist of both stationary and movable rails, and many different support and roller configurations. These designs will be critiqued and analyzed to determine which design will be pursued as the final design proposal. CONCLUSION This design effort will become successful by using what is known about past elevator design and taking what is now known about linear induction motors (LIMs). The two technologies will be blended together to create a radically new concept. The major requirement of this design effort will be to successfully demonstrate a feasible transition system for an ordnance/cargo elevator powered by LIMs. This system will allow the elevator to travel in three axes, while fulfilling the design and safety requirements set forth by the United States Navy. 6 REFERENCES 1. Poole, Kenneth J., Naval Surface Warfare Center - Carderock; Personal Conversation, 12 Sept 2003.. 2. McCammon, Thomas, 1997. U.S. Navy Shipboard Elevator. Elevator World Magazine; September 1997 Issue. Pp. 64-67. 3. Fabian, Lawrence, 2000. Going out on a L.I.M: Linear Induction Motors for Horizontal and Vertical Transport. Elevator World Magazine; March 2000 Issue. Pp. 63-67. 4. http://www.force.co.uk/, 29 September 2003. (No Authors Given) 5. http://www.me.utexas.edu/~uer/roller/tech.html, 29 September 2003. (No Authors Given) 6. Avallone and Baumeister, Ed., Marks' Standard Handbook for Mechanical Engineers, Tenth Edition, McGraw-Hill, 1996 7. Editorial. Linear-Motor-Driven Vertical Transportation System. Elevator World Magazine; September 1996 Issue. Pp. 66-73. 8. http://www.uspto.gov/, 28 September 2003. (No Authors Given) APPENDIX I – EXISTING PATENTS Note: All patent searches carried out on the United States Patent Office Website.[8] Patent Search for Elevators driven by Linear Induction Motors No Hits for “multi-directional elevators” or any variation. Multiple hits for elevators driven by linear induction motors. Search Criteria: “Linear Elevator”. Patent # 6,305,501 Elevator reluctance linear motor drive system Abstract A drive system for an elevator includes a drive machine by means of which the for moving and supporting an elevator car. The primary circuit of a linear motor is permanently fitted to a wall of a building while its secondary circuit is fitted in conjunction with the elevator car and moves with the elevator car. Pressurized air is supplied between the primary and secondary circuits of the reluctance-type linear motor to maintain an air gap between them. Inventors: Kahkipuro; Matti (Hyvinkaa, FI); Pelto-Huikko; Raimo (Vantaa, FI); Kallioniemi; Antti (Helsinki, FI) Assignee: Kone Corporation (Helsinki, FI) Appl. No.: 446063 Filed: March 14, 2000 PCT Filed: June 18, 1998 PCT NO: PCT/FI98/00531 371 Date: March 14, 2000 102(e) Date: March 14, 2000 PCT PUB.NO.: WO98/58866 PCT PUB. Date: December 30, 1998 The present invention relates to an elevator and in particular, to a drive system for an elevator. DESCRIPTION OF THE BACKGROUND ART In elevator technology, several methods are used to produce the motive power for elevators. A common method is to use a traction sheave connected to a rotating motor hoisting the elevator car by means of ropes, with a counterweight placed on the opposite side of the traction sheave to balance the load. Another established solution is found in hydraulic elevators, in which the hoisting power to move the car is obtained from hydraulic cylinders either directly or via ropes. Most modern elevators are based on these solutions, of which many variations have been developed. Although the above-mentioned elevator types have become established and are safe and reliable in operation, the solutions used in them comprise several factors that are objections of improvement and product development. For example, investigations are continuously being made to find ways of more effective utilisation of building space and reduction of energy consumption. For hydraulic elevators, the hoisting height is in practice limited to a few floors. By contrast, elevators with rope suspension have been installed in buildings as high as several hundred meters, in which case rope elongation and oscillation cause problems. Because of the rope suspension arrangements, the number of elevators in a shaft is practically limited to one. In addition to rope-suspended and hydraulic elevators, several solutions for the use of a linear motor in an elevator have been proposed. In this case the induction motor is completely located in the shaft space. Most linear elevator motors have been based on the induction motor principle, although other motor types, such as a linear motor based on permanent magnets have also been presented. Several different solutions have been proposed, but as yet it has not been possible to produce a competitive elevator. SUMMARY OF THE INVENTION The object of the present invention is to achieve a new elevator in which several drawbacks encountered in prior art solutions are avoided. The invention is based on a so-called switched reluctance linear motor or a variant developed from it, which makes use of the so-called microflux technique. In the switched reluctance motor, the windings of the linear motor are optionally placed either in a fixed primary circuit or in a movable secondary circuit. The motor is used to both move the car and support it by generating a force component in the direction of motion and a force component perpendicular to the direction of motion. The placement of the winding on the primary or secondary side can be selected separately for each application. According to a preferred embodiment of the invention it is utilised the combined effect of a linear motor and pneumatic air gap regulation. The linear motor is used to both move the car and support it by generating a force component in the direction of motion and a force component perpendicular to the direction of motion. The air gap between the primary and secondary circuits of the linear motor is maintained by means of the perpendicular component and pressurised air. According to a preferred embodiment of the invention, in a motor based on the microflux technique, called microflux motor, the windings are placed on both the primary and secondary sides, thus reducing the proportion of leakage flux and improving the power-to-weight ratio of the motor. The supply of current to the windings is so controlled that the magnetic flux will only pass through a minimal distance in the yoke part of the motor and that the flux loop will be completed in the first place via adjacent teeth. According to a preferred embodiment, the power is supplied to the windings using control equipment disposed along the entire length of the track of the elevator and each winding is controlled separately. Alternatively, several windings can be combined to form a group with common control. According to another alternative implementation of the invention, the pneumatic equipment comprises a source of pressurised air and a pipe system with nozzles, fitted substantially in the air gap between the primary and secondary circuits of the linear motor. The pressurised air keeps the air gap clean and generates a smooth air flow from the center of the air gap towards its edges. The alternatives regarding the structural solutions of the invention are to dispose the linear motor and pneumatic equipment on one side of the elevator car or to dispose the linear motor and pneumatic equipment on two or more sides of the elevator car. The former solution provides more freedom regarding the placement of the elevator in the building and an independence of a traditional elevator shaft. The latter solution allows more freedom of variation of the physical dimensions of the elevator-specific motor. In an embodiment of the invention relating especially to the structure of the linear motor, the tooth pitch of the primary and secondary circuits is effected by applying the vernier principle. The motor power can thus be uniformly distributed over the entire length of the active part of the motor, i.e. the movable secondary side. According to a further embodiment, the primary circuit and/or secondary circuit is coated with a plastic film on the surface facing the air gap. The effective air gap of the linear motor can thus be adjusted without increasing the pneumatically regulated air gap at the same time. The new type of motor solution of the invention provides several advantages in elevator technology. As the motor applies a lifting force directly to the elevator car, it eliminates the need for hoisting ropes, which are an object of regular maintenance and renewal. Readjustments due to rope elongation naturally become unnecessary. Correspondingly, no traction sheave and no diverting pulleys need to be installed. The counterweight and associated shaft equipment, such as counterweight guide rails, become superfluous. No separate machine room is needed, but the control and operating equipment can be placed in the elevator or in conjunction with the equipment at the landings. The travel of the elevator car in the elevator shaft is controlled by a pneumatic bearing system, so there are no conventional car guides and guide rails installed for them. Safety gears as used in current technology are also left out. The overall degree of utilisation of the elevator shaft is higher because the only equipment that needs to be installed in the elevator shaft in addition to the elevator car is the very flat magnetic circuits of the motor. The lifting height is unlimited without any special additional equipment or rigging necessitated by height. The elevator can be implemented as a external installation in which the elevator climbs along the external wall of the building, thus allowing a further space saving inside the building. In the elevator solution of the invention it is further possible to use a light car construction because the magnitude of the friction does not limit the minimum car weight as in the case of traction sheave elevators. Based on the degrees of freedom of the elevator of the invention and the limitations of conventional elevators, this new solution provides advantages especially in the case of very high and very short elevator shafts. Furthermore, the elevator solution of the present invention makes it possible to develop multiple-car elevator shafts and also transport systems combining vertical and horizontal movement. The switched reluctance motor has a considerably higher power-to-weight ratio than conventional motor solutions. In the microflux motor, the power-to-weight ratio can be further improved as compared even with the reluctance motor. Further scope of the applicability of the present invention will become apparent from the detailed description given hereinafter. However, it should be understood that the detailed description and specific examples, while indicating preferred embodiments of the invention, are given by way of illustration only, since various changes and modifications within the spirit and scope of the invention will become apparent to those skilled in the art from this detailed description. Patent # 5,203,432 United States Patent Grinaski 5,203,432 April 20, 1993 Flat linear motor driven elevator Abstract A flat, single-sided linear motor driven elevator minimizes a moment on a primary element assembly towards a secondary element by aligning and balancing a center of gravity of the primary element assembly along the plane of an air gap between the primary and secondary elements of the linear motor. Ropes supporting the primary element assembly are attached thereto, and weights are positioned on a side of the plane, other than the side of the plane on which the primary element is disposed, to balance the centers of gravity and thrust of the primary assembly along the plane. Inventors: Grinaski; Timothy J. (East Hartford, CT) Assignee: Otis Elevator Company (Farmington, CT) Appl. No.: 793056 Filed: November 15, 1991 Current U.S. Class: Intern'l Class: Field of Search: 187/251; 187/404; 310/12 B66B 017/12 187/18,17,94,112 310/12,13,14 TECHNICAL FIELD This invention relates to an elevator, and more particularly to an elevator driven by a flat linear motor. BACKGROUND OF THE INVENTION Usually, an elevator's drive sheave and motor are arranged above the elevator car in a machine room. In buildings, where space is at a premium, machine rooms are not desirable. Some elevators are powered by linear motors, which provide motive force for the elevator within a hoistway, and do not require a machine room. Some linear motor driven elevators have a tubular primary element disposed around a tubular secondary element. The tubular secondary element is hung from the top of the hoistway. At present, it is impractical to hang a secondary element over an extended rise. UK Patent Application 2,237,555 A to Toshiba shows another type of linear motor driven elevator which has a flat secondary and a flat primary element. The secondary element is affixed to the hoistway thereby avoiding the problem of hanging the secondary element from the top of the hoistway. The primary assembly of Toshiba is guided by the secondary thereby avoiding the necessity of mounting additional guide rails for the primary assembly. Flat linear elevator motors balance the relatively large normal forces (as compared to thrust forces) between the primary and secondary elements to maintain an air gap therebetween. If the air gap is too great the motor is inefficient. If the air gap is too small, the motor may short itself out. DISCLOSURE OF THE INVENTION It is an object of the invention to provide an elevator linear motor which minimizes the effect of forces between the primary element and secondary element of the linear motor. It is a further object of the invention to minimize the forces upon guides disposed between the primary and secondary elements of the linear motor. It is a further object of the invention to provide a linear motor which has an air gap that can be more readily controlled. According to the invention, a flat, single-sided linear motor driven elevator minimizes a moment of a primary element assembly towards the secondary element by aligning and balancing the coincident centers of gravity and thrust of the primary element assembly along a plane of an air gap between the primary and secondary elements of the linear motor. Ropes supporting the primary element assembly are attached thereto, and weights are positioned on a side of the plane, other than the side of the plane on which the primary element is disposed, to balance the center of gravity of the primary assembly along the plane. By aligning the primary element assembly along the plane, guides disposed between the primary and secondary elements are protected against excessive wear because the forces of any moment due to misalignment with the plane are minimized. Also, the air gap may be more closely controlled because the effect of moments on the primary assembly are minimized. These and other objects, features, and advantages of the present invention will become more apparent in light of the following detailed description of a best mode embodiment thereof, as illustrated in the accompanying drawing. Patent # 5,141,082 United States Patent Ishii , et al. 5,141,082 August 25, 1992 Linear motor elevator system Abstract A linear motor elevation system comprising an elongated magnetic induction member (21) mounted along the hoistway. The induction member (21) has a plurality of magnetic poles (21a) disposed at equal intervals along the hoistway so that they face toward the armature (27). An elevator car (4) or a counter weight has attached thereto a field magnet (26) disposed in a facing relationship with respect to the magnetic induction member (21) for generating magnetic poles in the induction member (21). The field magnet (26) comprises an iron core (23) having a U-shaped cross section including a central web portion on which a field winding 24 is wound and parallel flange portions extending from the web portion toward the magnetic induction member (21). An armature (27) comprising armature windings (25) wound on teeth formed in the magnetic induction member (21) is also disposed on the car (4) in a facing relationship with resepct to the magnetic induction member (21) for generating a progressive magnetic field acting on the magnetic induction member (21) to generate an electromagnetic drive force for moving the car (4) along the hoistway. The magnetic induction element (31) may have a guide surface which is in guiding engagement with guide rollers (41) mounted on the car (4) for guiding it along the hoistway. Inventors: Ishii; Toshiaki (all c/o Mitsubishi Denki Kabushiki Kaisha Inazawa Seisakusho 1, Hishimachi, Inazawa-shi, Aichi-ken, JP); Ikejima; Hiroyuki (all c/o Mitsubishi Denki Kabushiki Kaisha Inazawa Seisakusho 1, Hishimachi, Inazawa-shi, Aichi-ken, JP); Yosikawa; Hirosi (all c/o Mitsubishi Denki Kabushiki Kaisha Inazawa Seisakusho 1, Hishimachi, Inazawa-shi, Aichi-ken, JP); Sugita; Kazuhiko (all c/o Mitsubishi Denki Kabushiki Kaisha Inazawa Seisakusho 1, Hishimachi, Inazawa-shi, Aichi-ken, JP); Sakabe; Shigekazu (both c/o Mitsubishi Denki Kabushiki Kaisha Sangyo System Kenkyusho, 1-1,, Amagasakishi, Hyogo-ken, JP); Sugimoto; Hidehiko (both c/o Mitsubishi Denki Kabushiki Kaisha Sangyo System Kenkyusho, 1-1,, Amagasaki-shi, Hyogo-ken, JP); Maehara; Toshiaki (both c/o Mitsubishi Denki Kabushiki Kaisha Nagoya Seisakusho, 1-14,, Nagoya-shi, Aichi-ken, JP); Kisimoto; Takesi (both c/o Mitsubishi Denki Kabushiki Kaisha Nagoya Seisakusho, 1-14,, Nagoya-shi, Aichi-ken, JP) Appl. No.: 712102 Filed: June 7, 1991 SUMMARY OF THE INVENTION Accordingly, an object of the present invention is to provide a linear motor elevator system free from the above discussed problems of the conventional linear motor elevator system. Another object of the present invention is to provide a linear motor elevator system simple in structure. Another object of the present invention is to provide a linear motor elevator system easily manufactured and installed. A further object of the present invention is to provide a linear motor elevator system which is inexpensive. A still further object of the present invention is to provide a linear motor elevator system improved in the power factor of the linear motor. Another object of the present invention is to provide a linear motor elevator system improved in the linear motor structure. With the above objects in view, the linear motor elevator system comprises a movable body such as an elevator car or a counter weight disposed within a hoistway and an elongated magnetic induction member installed within the hoistway and extending along the hoistway. The elevator system also comprises a field magnet disposed on the movable body in a facing relationship with respect to the magnetic induction member for generating magnetic poles in the magnetic induction member. An armature is disposed on the movable body in a facing relationship with respect to the magnetic induction member so that a progressive magnetic field acting on the magnetic induction member is generated to generate a drive force for moving the movable member along the hoistway. The magnetic induction member may comprise an elongated magnetic plate extending along the hoistway and a plurality of magnetic poles disposed on the elongated plate at a substantially equal intervals along the hoistway, the magnetic poles facing toward the armature on the movable body. The field magnet may comprise an iron core having a substantially U-shaped cross section including a central web portion and parallel flange portions extending from the web portion, the flange portions extending toward the magnetic induction member, and a field winding disposed on the web portion of of the iron core. The armature may comprise a magnetic iron core having a plurality of teeth arranged along the magnetic induction member and a plurality of armature windings wound on the teeth. Alternatively, the linear motor elevator system of the present invention may comprises an elongated, rigid magnetic induction member extending along the hoistway and defining a guide surface for guiding the movable body therealong. A pair of field magnets are disposed on the movable body in a spaced, opposing relationship to each other for receiving the magnetic induction member therebetween, for generating magnetic poles in the magnetic induction member. Armatures are disposed on the field magnets in a facing relationship with respect to the magnetic induction member and generating progressive magnetic fields acting on the magnetic induction member to generate an electromagnetic drive force for moving the movable member along the hoistway. The movable body has mounted thereon a guide unit including a guide rollers which is in guided engagement with the guide surface on the magnetic induction element for guiding the movable body along the hoistway.