Increased Water Absorption of Wheat Flours through Attrition Grinding

advertisement

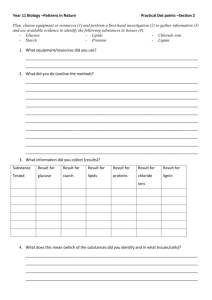

ALPINE Increased Water Absorption of Wheat Flours through Attrition Grinding Increased Water Absorption of Wheat Flours through Attrition Grinding A good water absorption of flours is a desire which may exist since the invention of dough making and baking. This is due to the manifold advantages the bakers could ascribe to an increased water content of dough and thereby of bread. Advantages of Increased Water Absorption Dry Dough Surface Good Machineability of Dough Increased Bread Yield Improved Fermentation Better Taste Percentage Points Water Absorption Cereal research could establish that Softer Crumb water binding of wheat flours is to be Delayed Staling attributed to protein, soluble pentosans Avoidance of Water Binding Additives and damaged starch. To increase the Longer Keepability amount of the very effective soluble pentosans no measure is known. The protein content can be influenced by breeding and agricultural measures (e.g. application of fertilizers). But, when the wheat has already entered the mill, damaged starch is the only component, which can be increased by Water Absorption of Wheat Flours milling procedures. Many efforts were made to achieve a higher water absorption of flour through damaging 30 starch than was given with usual 25 equipment, but, with limited success 20 only. Different investigators could not overcome a threshold of additional 10 15 percentage points Farinogram Water 10 Absorption though using aggressive 5 milling or crushing devices. As, at least up to the aforementioned 0 Sol. Damaged increase, in normal cases a high Protein Pentosan Starch content of damaged starch via the improved water absorption is advantageous for baking and the bread properties, it seems to be only fair to use the term “activated starch” instead of “damaged starch”. In the given limits the influence of activated (damaged) starch on the baking results were exactly examined by Farrand. He found out that the gluten matrix formed out of wheat protein and water is able to integrate a certain volume of starch. After activation starch has taken up a remarkable amount of water thereby Possible Measures for Influencing Water Binding of Wheat Flours expanding its volume. As long as the Protein Soluble Damaged starch with the thus increased volume Pentosans Starch can be still integrated in the gluten Breeding x (x) matrix the baking effect is advantaAgriculture x ? geous. Once the gluten matrix cannot Milling ? xx longer integrate and cover the swollen starch granules the given ruptures in the dough cells cause a loss of carbon dioxide ex fermentation, this loss being responsible for a decrease in bread volume. Thereby the benefit of starch activation is revealed to be dependent on the protein- respectively gluten-content of flour. For the gluten quality as well as the enzy1 matic status of the flours play an important role in this relation, the Farrand model unfortunately cannot be used for exact calculations. Good quality “hard” wheats show obviously a better response to milling efforts with respect to the content of activated starch. It is assumed that a firmer structure of the starch granules allows a more effective crushing, whereas the more elastic starch granules ex “weak” wheat varieties can better overcome the milling stress without being activated. Another theory ascribes the better activating properties of hard wheat starch to the strongly adhesive protein on the surface of the starch granules which is missing on weak wheat starch. Water Absorption Starch Activation As a result the efficiency of a milling process is not only depending on the equipment but on the wheat quality, too. A really accurate prediction of the activating performance therefore cannot be given, for the quality Influence of Wheat Quality on Efficiency of Starch Activation of a flour made of a commercial wheat is normally not exactly known. In Germany the poorer E wheats w.r.t. baking quality are characterised as “C” and “B” A whereas the better wheats are rated as “A” and “E” (Elite). B There are qualitative indications but no quantitative data in how C far this rating influences the Test Flour resulting content of activated Wheat Quality (German Classification) starch. Nevertheless an influence as given in the accessory graph has to be expected. The reference (test-) flour used for the below described examinations is a medium quality one. That intensity of the milling procedure correlates positive with starch activation and hence water absorption of flour can easily be understood. Roller mills and pin mills were extensively tested to which extent starch activation could be achieved. The results exhibited for both kind of mills a limit of additional 10 per cent points Farinogram Water Absorption. The particular reasons shall here not be discussed in depth. Some investigators found strong indications that ball milling of flour could be quite more effective in this regard. As the research was not followed up it can well be assumed that some restrictions caused by the used small scale equipment and the batch process could not be eliminated. 2 Having negotiated these first findings, the engineers and scientists of Hosokawa Alpine reflected upon the basics of the different milling processes. Pin milling seemed not to be a viable procedure to activate starch. The strong impact applied for a split second causes an elastic deformation and in a very short time the deformed starch granule recovers its original shape. Starch activation but was found to be due to an irreversible deformation of the granule, combined with the formation of fine fissures allowing water to enter and swell the granules. Comparison of Milling Principles Cylinder Ball Pin Stress, Shear Stress, Punch Impact Roller milling performed with a pair of cylinders rotating with different speed offers better measures to activate starch. UnforWorking Area of Cylinder and Ball tunately the necessary energy dissipation takes place in a very restricted area, i.e. the cylinder surface near the milling gap. The investigators found, what was to be expected: strong energy input resulted in 40 strongly increasing temperatures, thereby damaging flour protein, creating flaking effects or even causing fire hazards. d Cylinder: = 300 mm; d = 4.90 mm Ball: = 5 mm; d = 0.63 mm The ball milling (attrition) procedure is based on similar principles as roller milling. The space between cylinders or balls respectively in which starch granules possibly can be influenced and energy input may occur has a width from 0 up to 40. A calculation based on this assumption shows that milling balls (better: pearls) do offer not only an obviously higher specific surface but an energy dissipation area which is several orders of magnitude larger than that of cylinders. This allows a high specific energy input distributed on thousands and thousands contact places, each locally separated from the other. Overheating problems do not arise at all; if necessary, the cycled balls (pearls) can be cooled down with quite simple methods, e.g. air cooling. 3 Backbone of the designed attrition plant is the well-tried Hosokawa Hosokawa Alpine Ball Mill ATR Alpine ATR ball mill. The milling 1 2 pearls are passed through the milling chamber together with the flour to be milled. The pearls are then separated in a sieve and, in a cycle procedure, Legend: transported back to the feeder of the 1 Controlled Drive mill. This machine was in a first step 2 Right Angle Gear 3 combined with appropriate equipment 3 Stirring Axle 4 Stirring Rods to form a plant for the attrition 5 Controlled Conveyor treatment of wheat flour in which the flour is milled in a cycle procedure. 4 The created fine fraction is then separated by a classifying unit (Hosokawa Alpine ATS). The thus removed material is replaced by freshly 5 introduced unground flour. As it was assumed that starch activation preferably was achieved with the fine particles these are effectively extracted out of the process. It has to be checked, however, whether the assumed higher starch activation of the Circular Process 3 2 7 8 4 1 9 5 6 10 Legend: 1 Elevator 2 Ball Mill 3 Feeding Bin 4 Vibrating Sieve 5 Collector for Milling Pearls 6 Collecting Bin 7 Classifying Unit 8 Filter Separator 9 Aspiration 10 Outlet fine flour fraction is really given. For this purpose an analytical investigation was made. Evaluating the analytical data one has to consider that the process starts unbalanced as in the beginning the separated fine material has an increased protein content. The balance is given, when the separated flour has exactly the same protein content as the fed flour. In this status the cycled flour has a remarkable lower protein content. The set of obtained analytical data showed firstly that the balance of the process was given after 180 minutes. Furthermore it 4 Parameters of Original Flour, Delivered Flour and Circulated Flour in Balanced State of Process could be derived that the cycled flour - despite of its coarser particle size - exhibited nearly the same starch activation and Farinogram Water Absorption. Protein i. D.M. (%) 48421-Original F. 48421/9 180'-Fine FarinogramWA (%) 12.7 7.2 59.6 9.4 8.8 78.0 12.5 8.8 79.8 48421/9 180'-Coarse The conclusion is very pleasing: the quite complicated arrangement can be simplified. Act. Starch i. D.M. (%) The relevant pictures unveil that, compared with the circular process, the straight through process can work without a remarkable number of expensive components. Straight Through Process 2 3 Legend 1 2 3 4 5 6 7 4 1 7 6 5 Farinogram Water Absorption vs. Energy Input 95 90 85 Farinogram-WA in % The straight through process delivers an excellent correlation between specific energy input and water absorption. In the pilot plant an increase of approx. 30 percentage points Farinogram Water Absorption could be achieved. Higher values would have needed a stronger motor power. Based on these results in a commercial plant water absorption values of additional 40 percentage points will be realised. Elevator Ball Mill Feeding Bin Vibrating Sieve Collector for Pearls Outlet Aspiration R = 0.965 80 75 70 65 60 55 50 0 20 40 60 80 100 120 140 160 180 Specific Energy Input in kWh/t 5 200 The graph shown above is altered now. The additional water uptake can be ascribed to the extended amount of activated (damaged) starch. Farinogram-Units The course of the Farinogram is, compared with the Farinogram resulting from the original flour, not remarkably altered. Although nearly 30 percentage points more water was taken up the concerning Farinogram does not indicate any slackening of the dough what can be observed sometimes if flours are too finely milled. The quite normal appearance of the Farinogram, however, should not mislead to the expectation that a norFarinograms of Wheat Flour before and after Attrition Grinding mal baking result can be achieved with a dough having this 600 highly enhanced water WA 59.8 500 content. In this 400 context the afore300 mentioned has to be WA 88.1% pointed out: starch 200 activation, expressed 100 as increased water ab0 2 4 6 8 10 12 14 16 18 20 sorption, and gluten content has to be in an Time in Minutes optimum balance. Raster Electron Microscopy (SEM) examination can help to understand how the applied mechanical attack changes the structure of the starch granule thereby activating it. Normally the round starch granules are quite stable and elastic. After impact they easily recover their original shape. The first magnification shows, however, that after attrition grinding, they have flattened areas, “poles”, and a trend towards a polyedric shape may be detected. SEM-Photo of Wheat Flour after Attrition Grinding I 10 That may be not sufficient to explain the dramatically changed properties of the starch granules w. r. t. their water absorbing capability. A further, greater SEM-magnification reveals the reason: a lot of small fissures created by the specific influence of attrition grinding allows the water molecules to 6 easily enter and to penetrate into the starch granule. The water absorbed in this way shows a very strong bond to the starch; as already mentioned a release during dough kneading cannot be detected. SEM-Photo of Wheat Flour after Attrition Grinding II Viscosity in cp The temperature of the flour leaving the activating process does not exceed 1 40°C. This is not at all sufficient to inactivate the enzymes present in the flour. Consequently the Falling Number is not affected by the process. The same applies for the position of the viscogram-maximum the temperature of which does not shift remarkably. Of course it was expected that the level of the maximum viscosity decreased remarkably as it is shown in the accessory graph. Together with water the amylolytic enzymes can penetrate into the granules and effectively attack the amylose- and amylopectin-chains thereby breaking down the components developing the viscosity of a gelatinised flour slurry. As a second result the production of dextrins is strongly intensified with a lot of advantages (and a few disadvantages of course) causing an improved bread quality. So a very good Rapid Visco Analyser Maximum vs. Energy Input negative correlation is given between the specific energy 700.0 input and the height of the 600.0 viscogram maximum. 500.0 As already was pointed out it is most likely that the enhanced water absorption of 400.0 300.0 200.0 R = 0.943 95 100.0 90 0.0 20.0 40.0 60.0 85 80.0 100.0 120.0 140.0 160.0 180.0 200.0 Farinogram-WA in % 0.0 80 Attrition Grinding Specific Energy Input in kWh/t 75 70 flours through attrition grinding is 65 generated by activation (damage) of starch. Thus, the amount of 60 Original Flour Pin Mill Grinding damaged starch is rising with spe55 cific energy input. The correlation 50 between energy input and starch 0 20 40 60 80 100 120 140 160 180 Specific Energy Input in kWh/t damage (measured acc. to ICC Standard 164), however, is not satisfying. This may be due to disturbing influences on the analytical procedure which could not yet be tracked down. 7 200 The evidence, that attrition treatment (ball milling) is a method particularly useful for increasing water absorption in flour (through activating starch) is given by a comparison between pin milling and ball milling. Pin milling has an influence on the water absorption of flour, too, but the steepness of the correlation straight line is remarkably lower than with ball milling. The integration of an attrition plant for activation of flour starch into a milling flow sheet can be managed according to the millers needs. The two examples given are not an exhausting survey. Although enhanced water absorption is doubtless a desirable property of many wheat flours, it must be justified by an economic advantage for the usual broad utilization in bakeries. Some tables in this paper offer an instrument for an user to check whether this is the case for his particular purpose; some exemplary calculations are given. Nevertheless it has to be mentioned that very interesting ATR: Prices and Figures additional applications in the food production other than baking may exist. Flours with high water binding capacity will be e.g. useful as component in breading mixes and as general substitute for thickeners. For the resulting commercial benefit figures cannot yet be given: firstly the applications have to be realised by way of trials. Cost Price (€) 250,000 Throughput (kg/h) 500 Production Days/a 300 8-Hr.-Shifts per Day 2 Production Hours/a 4,800 Production (t/a) 2,400 Energy/t (kWh) 190 Energy Cost (€/kWh) Energy/a (kWh) -.045 456,000 8 ATR: Production Costs/a Depreciation 10 Years (€) Interest 6% (€) Energy Costs (€) Working Costs 0,1 Man/d (€) Cost of Repairs 2% (€) Total Costs (€) Costs (€ /t) 25,000 7,500 20,520 5,000 5,000 63,020 26 Cost Advantages through Attrition Ground Flour € /% kg kg € € kg € kg € kg Flour T. 550 23.0 100.0 23.0 95.0 21.9 98.6 22.7 99.6 22.9 Attr. Gr. Flour T. 550 25.6 - - 5.0 1.3 - - - - Pregelatinised Flour 55.0 - - - - 1.4 0.8 - - 150.0 - - - - - - 0.4 0.6 - 60.0 - 62.0 - 62.0 - 62.0 - 160.0 23.0 162.0 23.2 162.0 23.5 162.0 23.5 Guar Gum Water Total Sum Mat. Costs/1000 kg Dough 144 Difference/1000kg Dough 1.- 143 145 - 145 2.- 2.- Raw Material Costs in €/t "Sensoric" WA in % In some cases mills fulfil the market demand for flours with higher water absorption with the integration of high quality (Elite-) wheat in the fed wheat mix. As this kind of wheat is remarkably more expensive (e.g. €/t 145.- instead of €/t 130.- for faq-wheat) a partly replacement of E-wheat by attriCosts for Increased WA: E-Wheat / ATR-Treatment tion ground flour can help 350 to remarkably reduce the 70 resulting costs while 300 maintaining the property 60 250 of high water absorption. 50 200 One has to confess that 40 150 this will not work in cases 60 62 62 162.5 168.0 165.2 30 where the improved 100 baking power of the flour 20 50 with high E-wheat portion 10 0 is necessary. The term 0 “sensoric” WA was R R q q E E chosen for the measure is fa fa AT AT + + + + q q a a E E f f + + rather based on the q q fa fa practical findings of a WA Costs baking expert than on the faq = fair average quality result of a Farinograph examination. 9