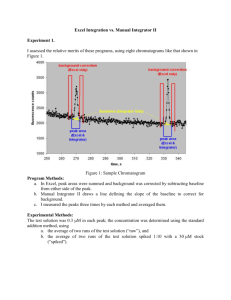

SIMULINK – Module 2

advertisement

SIMULINK – Module 2

Let’s consider the following.

1. Integrate a sine function.

sin d . The answer is cos 0 = 2

0

This could be visualized as a circuit

sine

function

integrator

output

To do this:

1. Go to Simulink library.

2. Open a new workspace.

3. Click on Commonly used blocks under Simulink

4. On the right column, find the integrator block, select it

and drag it into the workspace.

5. Go to sources (left column) under Simulink, find a

sinusoidal source, select it and drag it into the

workspace at the left of the integrator block.

6. Go to sink (left column), find a scope and drag it in at

the right of the integrator.

7. Connect them as shown

The output on the scope appears to be

If we want to change the initial starting value of the

integral, we double click the integrator and change it in

the parameter list.

How about changing the input source to a step function?

The view on the scope1 shows the input step function

And its integration is shown at the output scope (marked

scope):

How about using a single pulse function as an input? The

pulse function should appear as

Pulse height: 3

pulse width: 5

To produce this signal, we add two step functions.

Step function 1 would be a normal step function rising at

time = 1 of height 3.

Step function two would be a step function rising at time

= 5 of height 3, but added to the first one with reverse

sign (in effect, step function 2 is subtracted from step

function 1).

The two functions are added via a summing node

(polarities have to be changed). The entire system would

look like

The view on scope1 shows the input pulse:

The output on scope shows the integration of this

function.

Another example.

d2y

dy

Solve 2 a by sin t with a 0.01, and

dt

dt

b 0.2 .

This can be written as:

d2y

dt 2

Note that

( 0.01

dy

0.2 y ) sin t

dt

d2y

dt

2

dy

dt

integrator

dy

dt

integrator

y

The analog computer for this equation is:

The posted gain on gain1 a = 0.01, and on gain b = 0.2,

respectively.

The output on scope appears to be:

Lets make a 1.0 , and b 0.2

What if we switch these parameters? Now a 0.2 and

b 1.0 . With these,

PID controller.

The issue is: Control of a dynamic object (Plant)

R

error

_

controller

u

plant

Y

Plant is supposed to generate a signal y f (R) in response

to signal R . Three types of control are envisaged:

■ Proportional control: k p error

■ Integral control: k I (error)dt

d (error)

■ Differential control: kd

dt

The sum total control u at time t is therefore

de

dt

Note that the three control features are not independent.

Changing one affects the other.

u k pe k I edt kd

Suppose we have a dynamic system with a system equation

as follows:

m

d 2x

dt 2

b

dx

kx f (t )

dt

with the following parameters:

m 1

k 16 and f (t ) 1

b8

Our objective is to find out its

● rise time response (minimize)

● magnitude of the overshoot (minimize)

● magnitude of the steady state error (minimize)

We don’t know our system solution x(t ), but we assume its

Laplace transformation exists and is obtained as

t

L( x(t )) X s e st x(t )dt

0

Some typical transforms

(http://www.me.cmu.edu/ctms/modeling/tutorial/transferfunction/mainframes.htm)

Linearity

Time Domain

f(t) + g(t)

Function

x(t)

1st Derivative

x'(t)

2nd Derivative

x"(t)

nth Derivative

xn(t)

Frequency Domain

Also note some specific cases below

(http://www.intmath.com/Laplace-transformation/Table-laplace-transforms.php)

Time Function f(t)

f(t) =

-1

{F(s)}

Laplace Transform of f(t)

F(s) =

{ f(t)}

1

t (unit-ramp function)

tn (n, a positive integer)

eat

sin ωt

cos ωt

tng(t), for n = 1, 2, ...

t sin ωt

t cos ωt

g(at)

eatg(t)

eattn, for n = 1, 2, ...

Scale property

G(s − a) Shift property

te-t

1 − e-t/T

eatsin ωt

eatcos ωt

Thus, in our case, Laplace transformation of the equation

leads to (assuming all initial conditions are zero)

LT(model equation):

(ms 2 bs k ) X ( s) F ( s) or, in terms of transform

function

X (s)

1

ms bs k

2

F ( s ) tf F ( s )

The function X (s) is the response solution to the input

F (s) . Thus, the transform function determines the profile

of system response.

We try some approaches.

Case A: Open-loop solution (no feedback).

With output

Suppose we introduce proportional control only. Now the

transfer function changes to

TF

kp

s 2 8s (16 k p )

Suppose, we let k p 300 . Then the steady state solution

would be 300/316 = 0.95.

The output would appear as

With a significant overshoot. What if we accept it and

introduce the differential control on it? The transfer

function now changes to

TF

kd s k p

s 2 (8 kd ) s (16 k p )

Suppose we let kd 10 . Our system now changes to

With the scope output as

Note the improvement in response behavior. If we

introduce proportional integration error, our transform

function changes to (no derivative control)

TF

k p s kI

s3 8s 2 (16 k p ) s k I

Let k I 70 . Then our system would appear as

With the scope output (note the scale change)

With all the three controls in effect leads to the following

TF.

TF

kd s 2 k p s k I

s 3 (8 kd ) s 2 (16 k p ) s k I

With (kI , k p , kd ) (70,300,10) , we get

Not much improvement. But we note what we need to do.

Consider the following with a PID controller.

The following diagram shows the activity with

effectively three integrators.

The output on the scope depicts a forced damped

harmonic oscillation.