Module Title: PRODUCTION AND OPERATIONS MANAGEMENT

advertisement

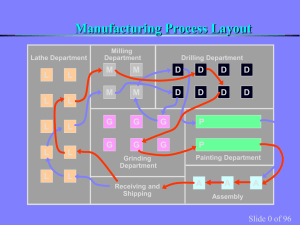

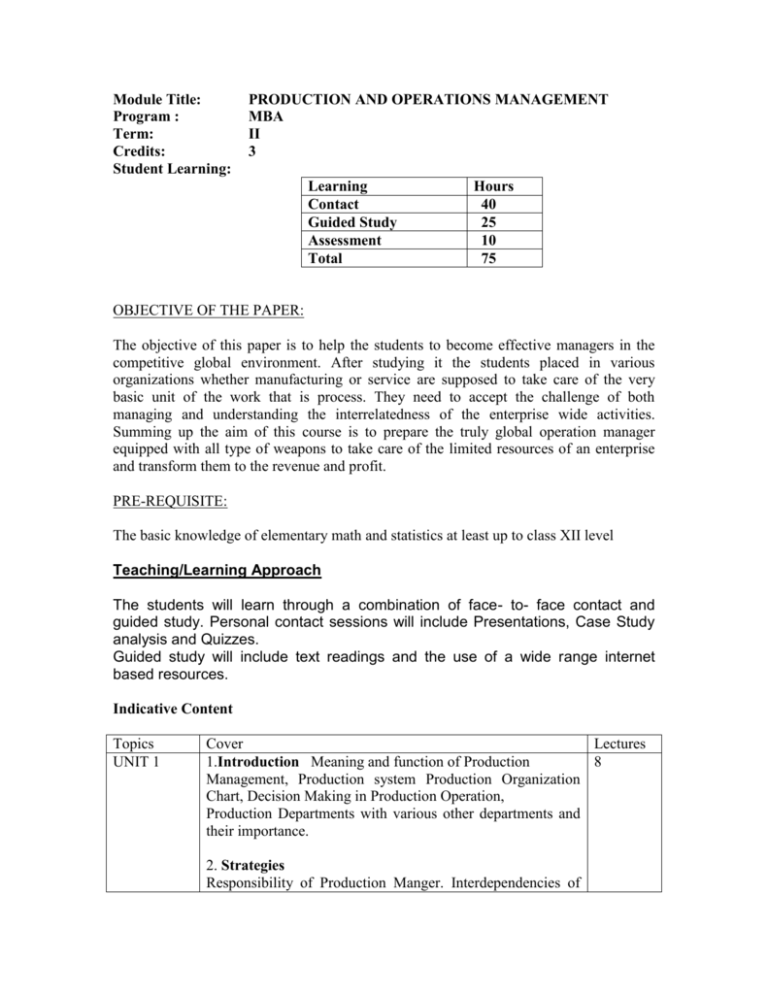

Module Title: Program : Term: Credits: Student Learning: PRODUCTION AND OPERATIONS MANAGEMENT MBA II 3 Learning Contact Guided Study Assessment Total Hours 40 25 10 75 OBJECTIVE OF THE PAPER: The objective of this paper is to help the students to become effective managers in the competitive global environment. After studying it the students placed in various organizations whether manufacturing or service are supposed to take care of the very basic unit of the work that is process. They need to accept the challenge of both managing and understanding the interrelatedness of the enterprise wide activities. Summing up the aim of this course is to prepare the truly global operation manager equipped with all type of weapons to take care of the limited resources of an enterprise and transform them to the revenue and profit. PRE-REQUISITE: The basic knowledge of elementary math and statistics at least up to class XII level Teaching/Learning Approach The students will learn through a combination of face- to- face contact and guided study. Personal contact sessions will include Presentations, Case Study analysis and Quizzes. Guided study will include text readings and the use of a wide range internet based resources. Indicative Content Topics UNIT 1 Cover Lectures 1.Introduction Meaning and function of Production 8 Management, Production system Production Organization Chart, Decision Making in Production Operation, Production Departments with various other departments and their importance. 2. Strategies Responsibility of Production Manger. Interdependencies of UNIT 2 UNIT3 UNIT4 UNIT 5 Operation strategies and decision making produce to stock and produce to order strategies, concept of using mixed strategies, advantages of having mixed strategies. 3. Long term planning/strategy 8 Facility location and facility layout. Factors affecting the location of facility, different types of layouts, product focused, process Focused, cellular and mixed layouts. Introduction to the methods for determining the location and layout of a facility. 4. Intermediate term planning/ strategy Capacities Planning, aggregate planning, hire and fire strategy etc. Identification and segregation of the operations based on the strategy selected. 5. Shop floor control Resource planning, sequencing and 8 scheduling, concept of JIT, manufacturing and assembly line balancing, preparation of Gantt Chart. 6. Project Management CPM, PERT forward pass and backward pass computations, resource leveling, resource allocation, and crashing of the project. 7. Inventory Management Inventory definition, types and models, managing the inventory, classification of inventories, MPS, MRP, ERP. 8. Work Study & Productivity Productivity improving techniques, Cost reduction approach, Work and Method study, Work Order, Production Control and its importance 9. Quality Concepts Production Quality Concepts and Internal Customer Approach, Introduction to the tools of quality management. 10. Safety Management Evolution of safety concepts, Electrical & Chemical hazards, ionizing and non ionizing Radiation, Personal protection, Material handling and shop floor design concepts, Environmental safety, fire prevention, introduction to OHSAS standards. Books for Reference: 8 8 1. Production and Operations Management K. Aswathappa, Himalaya Publishing House 2. Modern Production/Operation Management Buffa 3. Production/Operation Management Concepts E. Adam& J. Albert Prentice Hall 4. Theory & Practice of Production Operation Management S.N.Chary 5. Safety Management Grimaldi Simonds 6. Operations Management Russell & Taylor 7. Operations Management Ritzman & Krajewski 8. Operations Management Hanna & Newman 9. Production/Operation Management Manufacturing & Services Chase, Aquilano & Jacobs 10. Production & Operations Management , Norman Gaither, the Dryden Press 11. Operations Management, John O’ McClain & C. Joseph Thomas, PHI, 1987 12. Production and Operations Management, Martin K Starr, Cengage Learning India Edition. _____