Curriculam vitae

advertisement

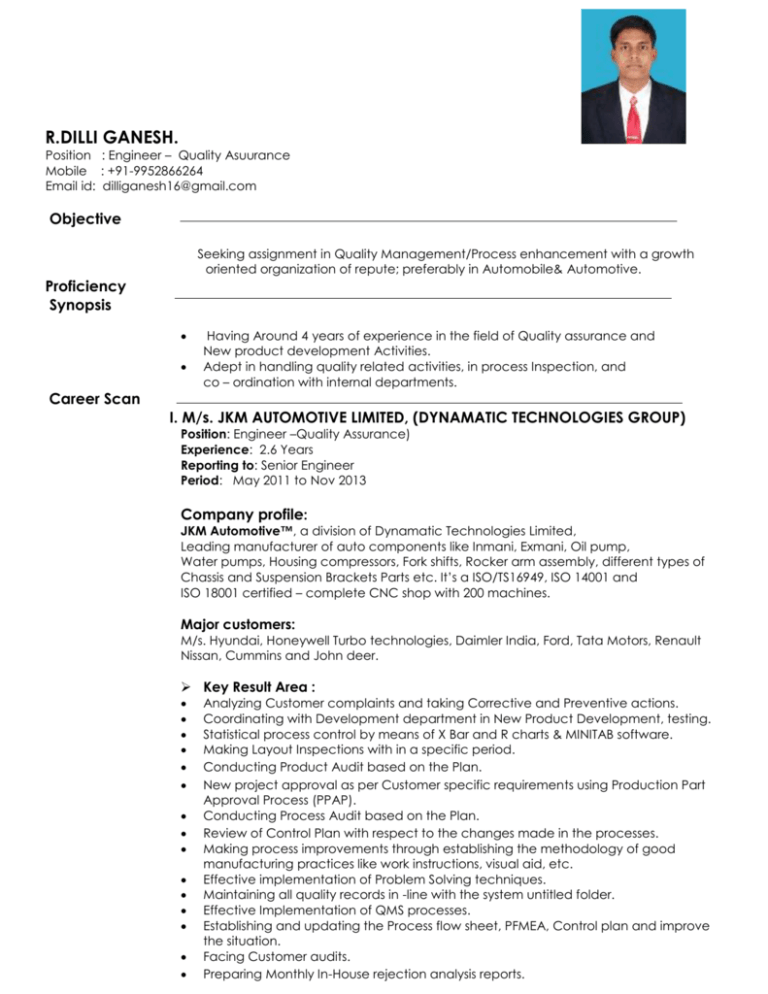

R.DILLI GANESH. Position : Engineer – Quality Asuurance Mobile : +91-9952866264 Email id: dilliganesh16@gmail.com Objective Seeking assignment in Quality Management/Process enhancement with a growth oriented organization of repute; preferably in Automobile& Automotive. Proficiency Synopsis Having Around 4 years of experience in the field of Quality assurance and New product development Activities. Adept in handling quality related activities, in process Inspection, and co – ordination with internal departments. Career Scan I. M/s. JKM AUTOMOTIVE LIMITED, (DYNAMATIC TECHNOLOGIES GROUP) Position: Engineer –Quality Assurance) Experience: 2.6 Years Reporting to: Senior Engineer Period: May 2011 to Nov 2013 Company profile: JKM Automotive™, a division of Dynamatic Technologies Limited, Leading manufacturer of auto components like Inmani, Exmani, Oil pump, Water pumps, Housing compressors, Fork shifts, Rocker arm assembly, different types of Chassis and Suspension Brackets Parts etc. It’s a ISO/TS16949, ISO 14001 and ISO 18001 certified – complete CNC shop with 200 machines. Major customers: M/s. Hyundai, Honeywell Turbo technologies, Daimler India, Ford, Tata Motors, Renault Nissan, Cummins and John deer. Key Result Area : Analyzing Customer complaints and taking Corrective and Preventive actions. Coordinating with Development department in New Product Development, testing. Statistical process control by means of X Bar and R charts & MINITAB software. Making Layout Inspections with in a specific period. Conducting Product Audit based on the Plan. New project approval as per Customer specific requirements using Production Part Approval Process (PPAP). Conducting Process Audit based on the Plan. Review of Control Plan with respect to the changes made in the processes. Making process improvements through establishing the methodology of good manufacturing practices like work instructions, visual aid, etc. Effective implementation of Problem Solving techniques. Maintaining all quality records in -line with the system untitled folder. Effective Implementation of QMS processes. Establishing and updating the Process flow sheet, PFMEA, Control plan and improve the situation. Facing Customer audits. Preparing Monthly In-House rejection analysis reports. Analyze the In house rejection and final inspection non – conformance. Analyze the complaint by using root cause analysis. Eliminate the manual error and develop / implement the poke – yoke system Maintain and track the effectiveness of non-conformance through final inspection and quality kaizen. II. SAMSUNG INDIA ELECTRONICS PVT LIMITED Position: Engineer – PQC (Process Quality - Washing Machine) Reporting to: Manager Period: Since Nov 2013 to till date Company profile: Samsung India Electronics Pvt Ltd in Sriperambadur is a leading provider of Home Appliances Electronic in Chennai. Samsung Electronics leads the global market in HighTech electronics manufacturing and digital media.Through innovative, reliable products and services, talented people, a responsible approach to business and global citizenship and collaboration with its partners and customers, Samsung is taking the world in imaginative new directions.A digital leader, a responsible global citizen, a multi-faceted family of companies, an ethical business - Samsung is all of these and more.At Samsung Group and Samsung Electronics, their products, their people and their approach to business are held to only the highest standards so that they can more effectively contribute to a better world Products: Washing Machine Front loading and Top loading, LED a Televisions, Refrigerator and Air Conditioner etc. Key Result Area : Input Problem Analysis and taking Corrective action. Critical to Quality data monitoring and Applying SPC tools on Daily basis. Defect trend Analysis and Taking Action to Reduce Defect. Making Process Improvement through Visual aids, Best Practices, Work instruction etc. Conducting Product Liability Audit and Premium Quality Audit on Daily Basis. Maintaining all quality records in -line with the system untitled folder. Verifying Patrol inspection on every two hours once. Good knowledge about daily 5S & Kaizen Activities. Significant Achievements : Achieved 0 PPM at customer end. Successfully developed different types of Chassis and Suspension Brackets Parts for ”BHARAT BENZ” a brand of Daimler India Commercial Vehicles Pvt Ltd,Chennai. Successfully Developed HEAVY DUTY & LIGHT DUTY TRUCK Parts For Daimler Project. Part in Preparing modified QCI (Quality control Instruction) to reduce the rejection Percentage. Reduction of in-house PPM to <500PPM by conducting meeting on daily basis and continual improvements. Awarded prizes for KAIZEN improvements In Equipment’s Co-ordinate Measuring Machine (ZEISS & Mitutoyo), Contour tracer (ZEISS), Millipore testing, Surface roughness tester, Linear Height gauge (2D), Profile projector & Table Measuring Instruments. Technical Qualification Year 2011: B E Mechanical in Pallavan Engineering College with 76%. Year 2008: DME in Pallavan Polytechnic College with 85% (DOTE). Training Exposure Statistical Process Control (SPC BY USING MINI TAB & ANALYTICAL) Internal Quality Auditor Measurement System Analysis (MSA) Failure Mode Effects Analysis (FMEA) Advance Product Quality Planning (APQP) Awareness of ISO/TS 16949 Quality improvement tools Kaizen 5 S Improvements Good communication and inter personal skills. Good leadership qualities. Willing to face any challenge encountered. Soft skills Personal Profile Father’s Name : M.Ruthira kotti. Date of Birth : 16/09/1990 Gender : Male Nationality : Indian Passport number : H9112659 Address : No. 151, vellai gate, Thimmasamuthiram post & Village Kanchipuram, Pin code-631 502. Declaration I hereby declare that all the details given above are true to the best of my Knowledge and belief. Place: Date: (R.DILLI GANESH)