Select Save and write down the Production Order

advertisement

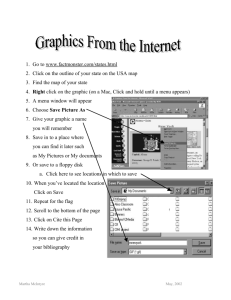

Manufacturing Execution (PP) Plug and Play Lab #5 Objectives: To demonstrate the manufacturing execution cycle from releasing a production order into production operations through deliver of finished production output into inventory. Exercises: Create a Production Order Release the Production Order to the shop-floor Issue required materials for the Production Order Confirm the progress/completion of the order Receive the completed quantity of the Production Order into stock Display completed order Display the material document To Get Started: If necessary, ask your lab Instructor to explain SAP log-on process. Complete the following exercises. You do not need to hand anything in to your instructor. The SAP R/3 system will track your progress as you execute the assignment. Your unique student number (XXX) for this exercise has been previously supplied to you by the instructor. This is for you ONLY. Do not share this number with anyone! Use the student number (XXX) as required during the exercise when asked for a student number. SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-1 Manufacturing Execution (PP) Step 1—Create a Production Order. Menu Path: Logistics Production Production Control Order Create With material Enter: Field Material Production Plant Order Type Data 2300-101 3000 PP01 Select the green check mark On the “Production Order Create: Header” Screen, enter: Field Total Quant. Finish Date Schedule Type Data 10 Last working day of next month Backwards Select the green check mark Note: The system is now busy doing the following tasks: TRANSFERING MATERIAL ROUTING INTO THE PRODUCTION ORDER TRANSFERING MATERIAL BOM INTO THE PRODUCTION ORDER RESERVING NEEDED STOCK FOR MATERIALS PLACING CAPACITY REQUIREMENTS ON WORK CENTERS SCHEDULING THE PRODUCTION ORDER CALCULATING PLANNED COSTS FOR THE ORDER Write down the following dates for the order: Basic Dates Finish _________________ Start _________________ Schedule Dates Finish _____________________ Start _____________________ Release _____________________ Select Save and write down the Production Order number __________________________________________________________________ Write down the message on the status bar __________________________________________________________________ Menu Path: Return to the Easy Access Menu SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-2 Manufacturing Execution (PP) Step 2—Release the Production Order to the Shop Floor. Menu Path: Logistics Production Production Control Order Change Enter: Production order number (if it is not defaulted) Select the green check mark. What is the status of the order? _________________________ Menu Path: Functions Release What is the system status now? _________________________ Save the Production Order Write down the message on the status bar ___________________________________________________________________ Menu Path: Return to the Easy Access Menu SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-3 Manufacturing Execution (PP) Step 3—Issue materials to the Production Order. Menu Path: Logistics Production Production Control Goods Movements Goods Issue Click on “To Order” Button on the application tool bar Enter Production order number xxxxxxx Storage location 0001 Select the green check mark to continue Select Save and write down the document number ___________________________________________________________________ Write down the message on the status bar ___________________________________________________________________ Menu Path: Return to the Easy Access Menu SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-4 Manufacturing Execution (PP) Step 4—Completion of the Production Order. Menu Path: Logistics Production Production Control Confirmation Enter For Order Enter: Production order number Select Enter Select the final confirmation radio button Yield to Conf.: should be 10 which is the production order quantity. Select Save Write down the message on the status bar ________________________________________________________________ Menu Path: Return to the Easy Access Menu SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-5 Manufacturing Execution (PP) Step 5—Receive Production Order output into Inventory Control. Menu Path: Logistics Production Production Control Goods Movements Goods Receipt Click on the box “To Order” Enter: Field MOVEMENT TYPE ORDER STORAGE LOCATION PLANT Data 101 YOUR PRODUCTION ORDER NO 0001 3000 Select Enter Select Save Write down the Material Document Number __________________________________________________________________ Write down the message on the status bar ___________________________________________________________________ Menu Path: Return to the Easy Access Menu SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-6 Manufacturing Execution (PP) Step 6—Display completed Production Order. Menu Path: Logistics Production Production Control Order Display Enter: Your production order number Select enter What is the Production Order Status ___________________________________________________________________ Click on Blue icon with i TO VIEW the DESCRIPTION OF STATUS. Write down the message on the status bar ___________________________________________________________________ Menu Path: Return to the Easy Access Menu SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-7 Manufacturing Execution (PP) Step 7—Display the material document for the Production Order. Menu Path: Logistics Material management Inventory Management Material Document Display Enter: Material document number Mat. Doc. Year Current Year Select Enter Select ACCOUNTING DOCS… Review the information by double-clicking on each of the documents. This reveals how the actions in logistics (such as receipt of materials) are fully integrated with the financial and managerial accounting modules. Write down the message on the status bar ___________________________________________________________________ Menu Path: Return to the Easy Access Menu Congratulations, you've successfully completed Plug and Play Introductory Course Lab #5! SAP America, 2003 Plug & Play Introductory Course The University of South Dakota California State University, Chico 5-8